A method for manufacturing modular recyclable wooden beer boxes

A manufacturing method and modular technology, applied in the field of packaging engineering, can solve problems such as poor environmental friendliness, short service life, and fast aging speed, and achieve the effects of increasing the number of recycling and reuse, low production input costs, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

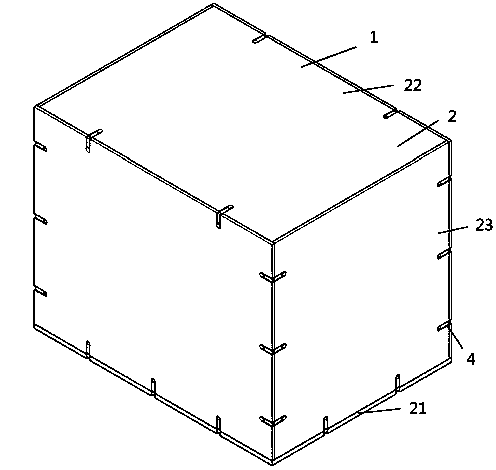

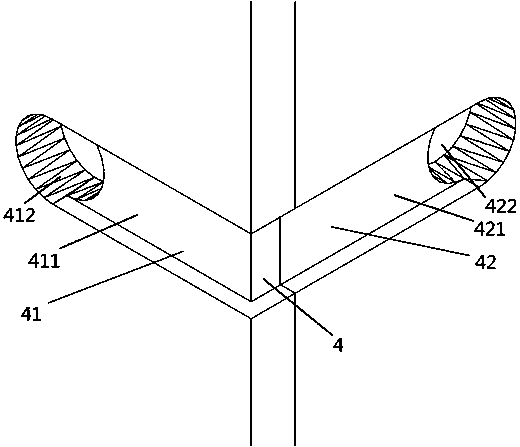

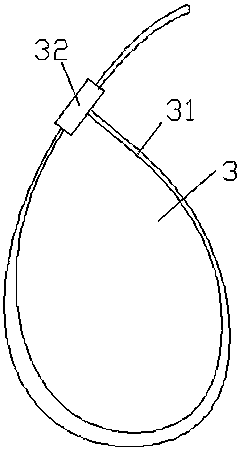

[0016] Such as Figure 1~3 As shown, a method for manufacturing a modularized recyclable wooden beer box, the modularized recyclable wooden beer box includes a box body 1, and the box body 1 is formed by splicing several wooden boards 2, any two adjacent The wooden boards 2 are respectively arranged at intervals at the joints to provide buckles 3 to buckle two adjacent wooden boards 2 groove groups 4, and each groove group 4 is correspondingly provided with at least one buckle 3. The buckle 3 includes a belt-shaped main body 31, and the head end of the belt-shaped main body 31 is covered with a ring-shaped body 32 for the end of the belt-shaped main body 31 to pass through and be fixed. The structure of the buckle 3 is similar to nylon on the market The cable tie, the groove group 4 includes a first groove 41 arranged on the outer side of one wooden board 2 in any two adjacent wooden boards 2 and a second groove arranged on the outer side of the other wooden board 2 42. Both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com