Large timber milling turning lathe

A wood and lathe technology, applied in the field of lathes, can solve the problems of low processing precision and low degree of automation of processing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

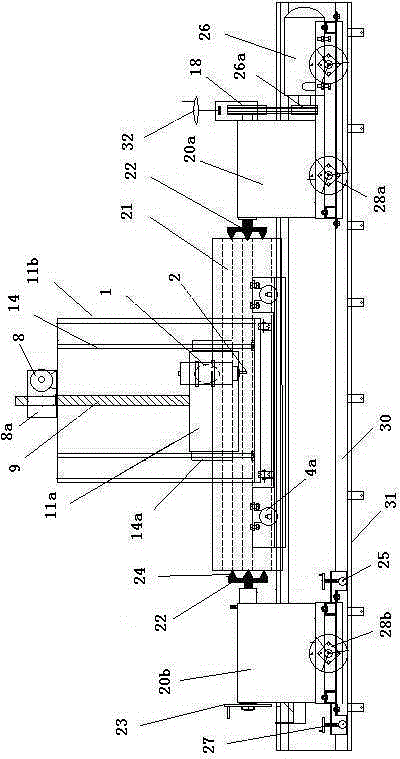

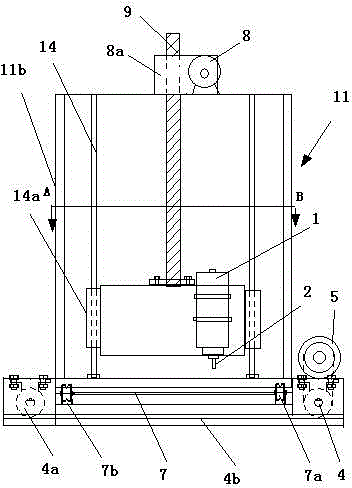

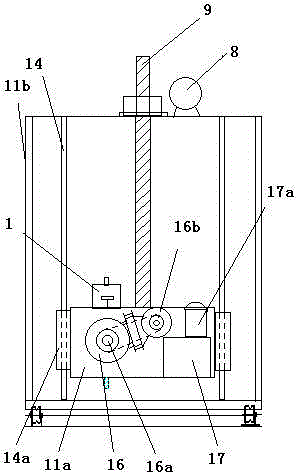

[0013] The technical solution of the present invention is a large wood milling and turning lathe, figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 It is a schematic diagram of the front enlarged structure of the movement in the rack, image 3 It is a schematic diagram of the back structure of the movement in the rack. Figure 4 It is the edge of the movement in the frame figure 2 Schematic diagram of the top view of the A-B direction in the middle.

[0014] This invention comprises a wood processing machine base 12 and a wood fixed base 31 parallel to the machine base 12. The machine base 12 is provided with a guide rail and a sports car 11 moving along the guide rail X, Y directions, and the base 31 is provided with a top seat 20a and a tailstock. 20b, the sports car 11 is provided with a frame 11b, the frame 11b is provided with a movement 11a, the movement 11a is connected with a driving device in the Y-axis direction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com