Preparation method for carbon-based catalyst of composite metal

A carbon catalyst and composite metal technology, which is applied in the field of carbon catalyst preparation, can solve the problems of few reusable times, poor catalyst stability, complicated preparation process, etc., and achieves many reusable times, strong selectivity, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of the carbon catalyst of composite metal of the present invention, first coconut shell charcoal is crushed and screened, and 10 g of coconut shell charcoal with a particle diameter in the range of 80 to 100 mesh is placed in a flask, 50ml of water is added, and heated to 40° C.; Then pass through ozone to oxidize for 18 hours, take it out and dry it, put it into a pre-configured compound solution with 20% solute (the ratio of the four compounds of CuSO4, KMnO4, AlCl3 and TiO2 is 1:1:1:2), and heat to reflux 4h, and then placed in a high-temperature heating furnace, heated to 800°C; and kept under a pressure of 0.2MPa and calcined for 4h to obtain a catalyst for the hydrogenation reaction of fatty nitriles.

Embodiment 2

[0023] The preparation method of the carbon catalyst of composite metal of the present invention, first coconut shell charcoal is crushed and screened, and 10 g of coconut shell charcoal with a particle diameter in the range of 80 to 100 mesh is placed in a flask, 50ml of water is added, and heated to 50° C.; Then add ozone, 30-50% nitric acid or sulfuric acid to oxidize for 21 hours, take it out and dry it, and put it into a pre-configured solute that is 30% in a composite solution (CuSO4, KMnO4, AlCl3 and TiO2 The ratio of four compounds is 1:1: 1.5:2.5), heated to reflux for 5 hours, then placed in a high-temperature heating furnace, heated to 900°C; and kept under a pressure of 0.3 MPa for 6 hours to obtain a catalyst for the hydrogenation reaction of fatty nitriles.

Embodiment 3

[0025] The preparation method of the carbon catalyst of composite metal of the present invention, woody charcoal and coal quality: after 1:1 mixing earlier, pulverize and sieve, get particle diameter and place 10 g of charcoal in the scope of 70 ~ 120 mesh in a flask, add 50ml of water , heated to 60 ° C;, then add ozone, 30-50% nitric acid or sulfuric acid to oxidize for 24 h, take it out and dry it, put it into a pre-configured compound solution with 40% solute (CuSO4, KMnO4, AlCl3 and TiO2 four kinds The ratio of the compound is 1:1:2:3), heated to reflux for 6h, and then placed in a high-temperature heating furnace, heated to 1000°C; after calcination at a pressure of 0.4MPa for 8h, a catalyst for the hydrogenation reaction of fatty nitriles was obtained.

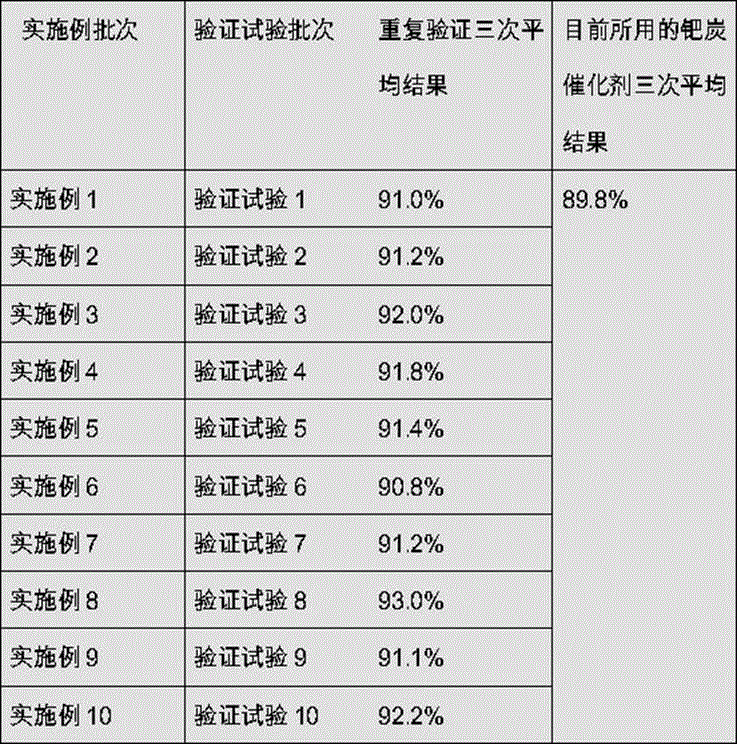

[0026] Examples 4-10 are obtained by changing the ratio of activated carbon with different particle sizes, the type and concentration of oxidant, oxidation time, calcination temperature and pressure and other conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com