Preparation of expanded graphite through compound modification and application of expanded graphite to printing and dyeing wastewater treatment

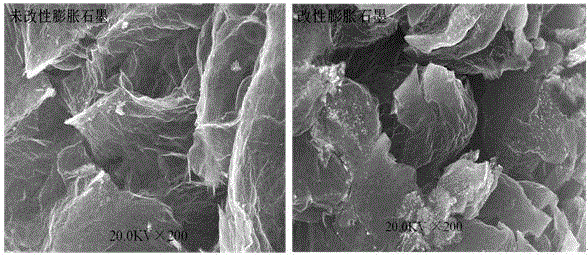

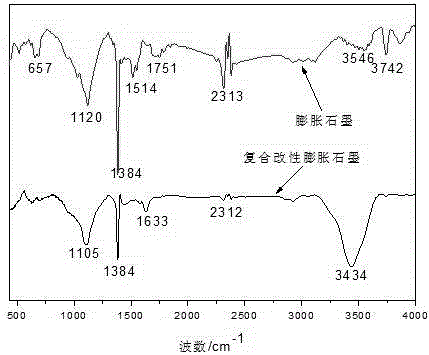

A technology of expanded graphite and composite modification, applied in the direction of adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc., to achieve the effect of improving adsorption capacity, increasing pore volume, and increasing surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

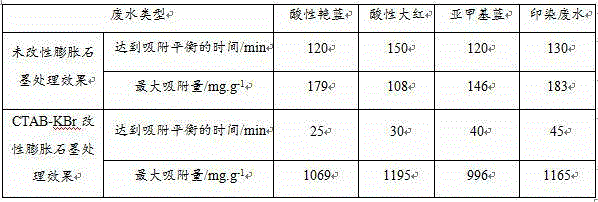

[0015] A certain amount of expandable graphite prepared from natural flake graphite is soaked in the ethanol solution of CTAB-KBr at a certain temperature, washed with water, dried, and expanded to obtain modified expanded graphite. Among them, CTAB and KBr The concentrations are 0.02mol / L and 0.05mol / L respectively, the ratio of expandable graphite to the solution is 1:0.2, the immersion temperature is 30°C, the immersion time is 5h, and the expansion equipment is a muffle furnace. The prepared modified expanded graphite was subjected to adsorption treatment of acid brilliant blue, acid scarlet, methylene blue and printing and dyeing wastewater at 30°C, and the maximum adsorption capacity was 219mg / g, 192mg / g, 181mg / g, 201mg / g, The time required to reach adsorption equilibrium is 150 min, 160 min, 180 min, 150 min.

Embodiment example 2

[0017] A certain amount of expandable graphite prepared from natural flake graphite is soaked in the ethanol solution of CTAB-KBr at a certain temperature, washed with water, dried, and expanded to obtain modified expanded graphite. Among them, CTAB and KBr The concentrations are 0.08mol / L and 0.2mol / L respectively, the ratio of expandable graphite to the solution is 1:0.2, the soaking temperature is 80°C and the soaking time is 8h, and the expansion equipment is a low-temperature electric furnace. The prepared modified expanded graphite is adsorbed on acid brilliant blue, acid scarlet, methylene blue and printing and dyeing wastewater at 30°C. The maximum adsorption capacity is 307mg / g, 279mg / g, 332mg / g, 321mg / g, reaching The time required for adsorption equilibrium was 180 min, 200 min, 180 min, and 180 min, respectively.

Embodiment example 3

[0019] A certain amount of expandable graphite prepared from natural flake graphite is soaked in an aqueous solution of CTAB-KBr at a certain temperature, washed with water, dried, and expanded to obtain modified expanded graphite, wherein the concentration of CTAB and KBr 0.08mol / L and 0.1mol / L respectively, the ratio of expandable graphite to solution is 1:0.2, the soaking temperature is 60°C and the soaking time is 5h, and the expansion equipment is a low-temperature electric furnace. The prepared modified expanded graphite is adsorbed on acid brilliant blue, acid scarlet, methylene blue and printing and dyeing wastewater under the condition of 30°C. The adsorption equilibrium time was 25 min, 30 min, 40 min, 45 min, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com