Preparation of PIMs film having a cardo structure and applications of the film in the field of gas separation

A hinge structure, PIM-1 technology, applied in the fields of recovery, CO2 separation, and capture, can solve the problems of insufficient membrane separation performance and restrictions on the application of membrane separation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

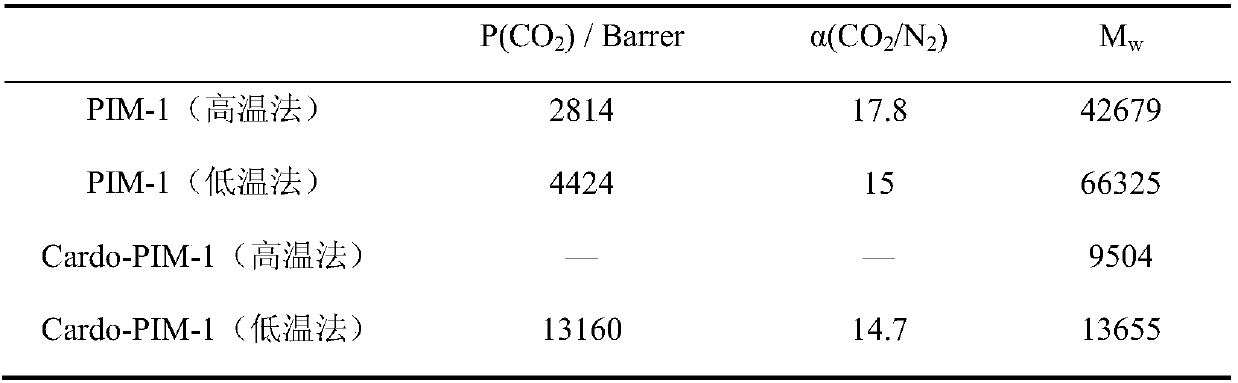

Embodiment 1

[0030] In a nitrogen atmosphere, take a certain proportion of TTSBI, TFTPN and anhydrous K 2 CO 3 Dissolve in an appropriate amount of DMF, heat and reflux at 140°C for 1 hour, pour into sufficient deionized water to precipitate and filter after cooling, heat and reflux in hydrochloric acid solution for 3 hours, filter, wash with water until neutral, wash with methanol 3 to 5 times, and vacuum dry Dry in oven at 120° for 24h. Take a certain amount of PIM-1 synthesized by the high-temperature method and dissolve it in chloroform to make a casting solution with a mass fraction of 3%, stir it overnight until it is fully dissolved, filter to remove the residue, flow the solution on the PAN bottom film to form a film, and dry it at room temperature After 24 hours, it was vacuum dried for 24 hours to obtain a PIM-1 gas separation membrane.

[0031] Test gas separation performance:

[0032] Pco 2 =2814Barrer

[0033] alpha i / j =17.8

Embodiment 2

[0035] In a nitrogen atmosphere, take a certain proportion of TTSBI, TFTPN and anhydrous K 2 CO 3 Dissolve in an appropriate amount of DMAc, heat and reflux at 65°C for 72 hours, pour into sufficient deionized water to precipitate and filter after cooling, heat and reflux in hydrochloric acid solution for 3 hours, filter, wash with water until neutral, wash with methanol 3 to 5 times, and vacuum dry Dry in oven at 120° for 24h. Take a certain amount of PIM-1 synthesized by the low-temperature method and dissolve it in chloroform to form a casting solution with a mass fraction of 3%, stir it overnight until it is fully dissolved, filter to remove the residue, flow the solution on the PS bottom film to form a film, and dry it at room temperature After 24 hours, it was vacuum dried for 24 hours to obtain a PIM-1 gas separation membrane.

[0036] Test gas separation performance:

[0037] Pco 2 =4424Barrer

[0038] alpha i / j =15

example 3

[0040]In a nitrogen atmosphere, take a certain proportion of TTSBI, BDPF, TFTPN and anhydrous K 2 CO 3 Dissolve in an appropriate amount of DMF, heat and reflux at 140°C for 1 hour, pour into sufficient deionized water to precipitate and filter after cooling, heat and reflux in hydrochloric acid solution for 3 hours, filter, wash with water until neutral, wash with methanol 3 to 5 times, and vacuum dry Dry in oven at 120° for 24h. Take a certain amount of Cardo-PIM-1 synthesized by the high-temperature method and dissolve it in chloroform to form a casting solution with a mass fraction of 3%. Stir it overnight until it is fully dissolved and then filter to remove the residue. Drying under vacuum for 24 hours and then vacuum drying for 24 hours gave Cardo-PIM-1 gas separation membrane.

[0041] Test gas separation performance:

[0042] The polymer has a low molecular weight and cannot form a dense film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com