High-efficiency broad width air-permeable fancy reflection material and preparation method thereof

A reflective material and high-efficiency technology, applied in optics, optical components, instruments, etc., can solve the problems of lack of breathability, sweat absorption, single style, etc., and achieve the effect of improving reflectivity, clear patterns, and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

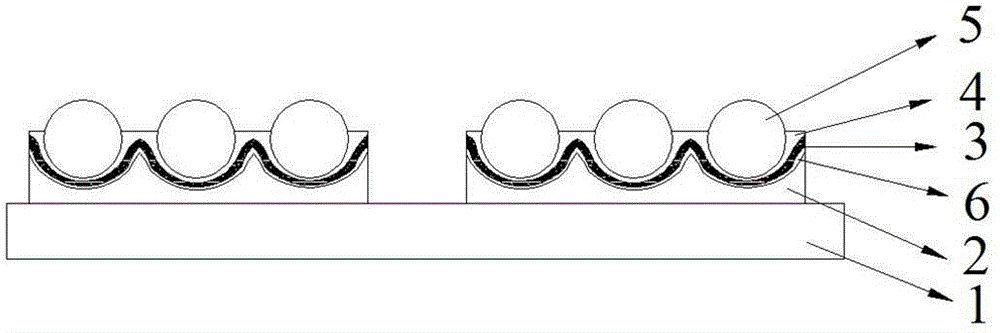

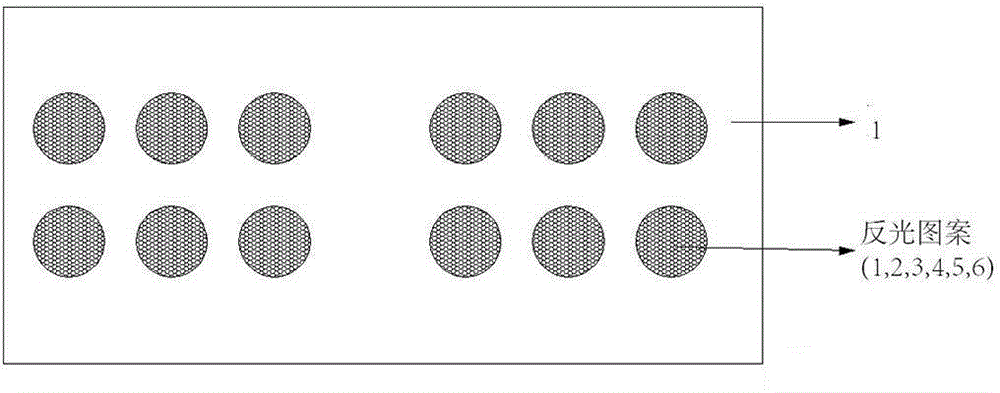

[0049] Kind of like figure 1 The high-efficiency and wide-width air-permeable fancy reflective material includes a substrate 1, a hot-melt adhesive film layer 2, a composite adhesive layer 6, a plating layer 3, a focusing layer 4 and a glass bead layer 5, on which part of the substrate 1 A hot melt adhesive film layer 2 is provided, a composite adhesive layer 6 is provided on the hot melt adhesive film layer 2, a plating layer 3 is provided on the composite adhesive layer 6, and a focusing layer 4 is provided on the plating layer 3. The focusing layer 4 is provided with a glass microbead layer 5, and the hot melt adhesive film layer 2 has a fancy pattern.

[0050] Here, the substrate is selected from chemical fiber cloth, TC cloth, stretch cloth, Oxford cloth, cotton flame retardant cloth, blended flame retardant cloth, aramid flame retardant cloth, PU leather, leather, PVC leather, warp knitted fabric, bird One of eye cloth, nylon spinning, polyester taffeta, and paper.

[0051] ...

Embodiment 2

[0056] Example 2: Method for preparing the high-efficiency wide-width air-permeable fancy reflective material of Example 1

[0057] A method for preparing the high-efficiency wide-width air-permeable fancy reflective material as described in Example 1, including the following steps:

[0058] (1) Implant glass beads: Place the PE / PET composite film in a heated roller, and the temperature is controlled between 140°C. As the PE film melts, the single layer of glass beads settle on the PE film. After cooling, the single-layer glass beads are fixed on the PE / PET composite film, thereby realizing bead planting;

[0059] (2) Focusing layer: coating the coating on the surface of the glass beads to form a focusing layer concentric with the glass beads, and drying the solvent in an oven to form a film, which is called a bead planting film;

[0060] (3) Coating: through resistance heating, it transforms from solid state to gaseous state, and after meeting the bead film, it condenses into a coati...

Embodiment 3

[0070] Example 3: Method for preparing the high-efficiency wide-width air-permeable fancy reflective material of Example 1

[0071] According to the method of Example 2, the difference is that the temperature in step (1) is controlled between 220° C., and the protrusion height of the convex roller in step (5) is 2 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com