Method for analyzing glucosamine content in whey protein glycosylation product by reverse-phase high performance liquid chromatography (RP-HPLC)

A reverse high-performance liquid phase and glucosamine technology, applied in the field of detection and analysis, can solve the problems of cumbersome processing and achieve the effects of convenient and simple operation, high sensitivity and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

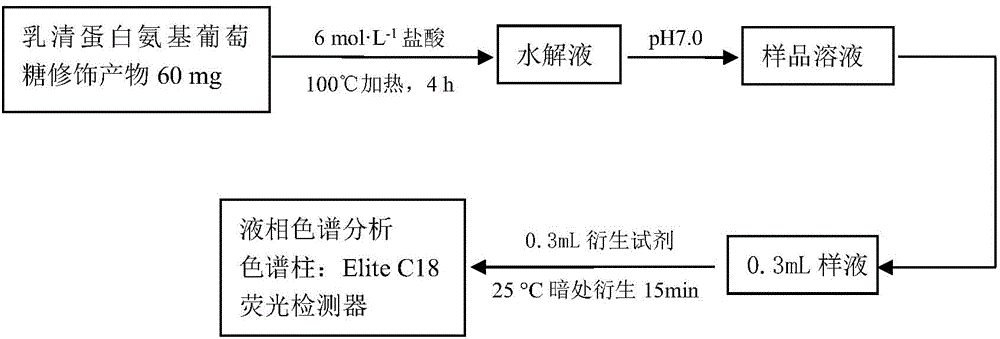

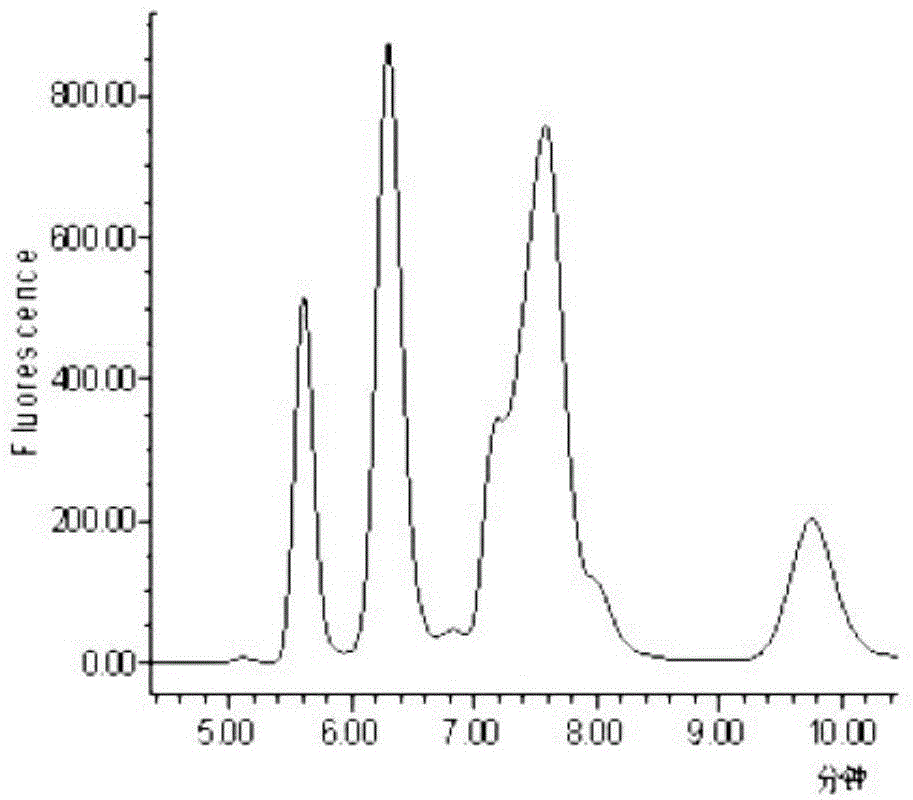

[0021] (1) Accurately weigh 60mg of whey protein glucosamine glycosylation product, add it to a hydrolysis bottle, add 5ml of 6mol / L hydrochloric acid to seal it, hydrolyze it at 100°C for 4 hours, take 1ml of the hydrolyzate, adjust the pH to 7.0, and Dilute to 25ml with pure water.

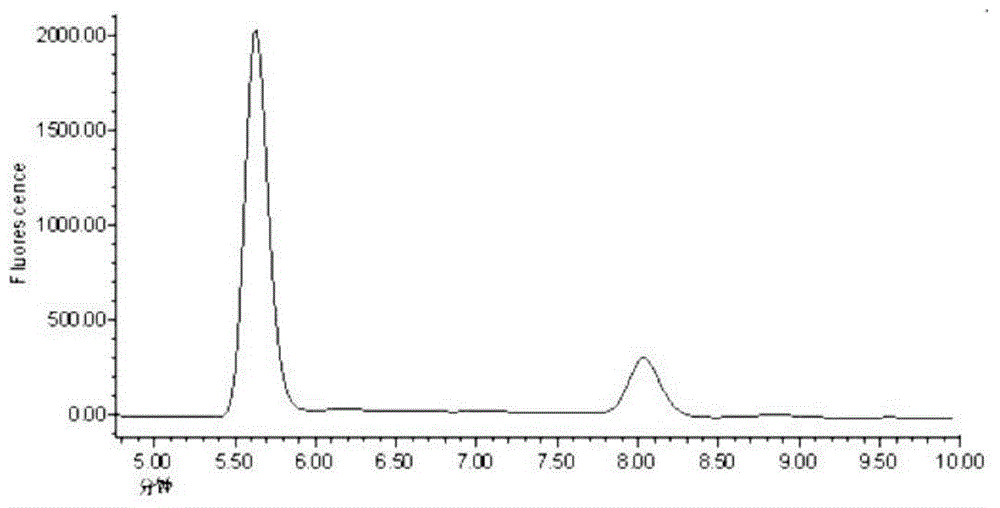

[0022] (2) Take 60 mg of raw whey protein, put it in a hydrolysis bottle, add 5 ml of 6 mol / L hydrochloric acid to seal it, hydrolyze it at 100°C for 4 hours, take 1 ml of the hydrolyzate, adjust the pH to 7.0, and dilute to 25 ml with ultrapure water.

[0023] (3) Add 0.7ml of boric acid buffer solution and 0.3ml of derivatization reagent to the sample and blank treatment solution obtained from step (1) and step (2), and mix well. Buffer and 0.1ml 3-mercaptopropionic acid, derivatized at 25°C for 15min in the dark.

[0024] (4) The derivatized sample liquid is subjected to reverse high-performance liquid chromatography analysis, the chromatographic column is Elite C18, and the chromatographic ...

Embodiment 2

[0026] (1) Accurately weigh 60mg of whey protein glucosamine glycosylation product, add it to a hydrolysis bottle, add 5ml of 6mol / L hydrochloric acid to seal it, hydrolyze it at 100°C for 3h, take 1ml of the hydrolyzate, adjust the pH to 7.0, and Dilute to 25ml with pure water.

[0027] (2) Take 60 mg of raw whey protein, put it in a hydrolysis bottle, add 5 ml of 6 mol / L hydrochloric acid to seal it, hydrolyze it at 100°C for 3 hours, take 1 ml of the hydrolyzed solution, adjust the pH to 7.0, and dilute to 25 ml with ultrapure water.

[0028] (3) Add 0.7ml of boric acid buffer solution and 0.3ml of derivatization reagent to the sample and blank treatment solution obtained from step (1) and step (2), and mix well. Buffer and 0.1mL 3-mercaptopropionic acid, derivatized at 25°C for 12min in the dark.

[0029] (4) The derivatized sample liquid is subjected to reverse high-performance liquid chromatography analysis, the chromatographic column is Elite C18, and the chromatograph...

Embodiment 3

[0031] (1) Accurately weigh 60mg of whey protein glucosamine glycosylation product, add it to a hydrolysis bottle, add 5ml of 6mol / L hydrochloric acid to seal, hydrolyze at 100°C for 5h, take 1ml of hydrolyzate, adjust the pH to 7.0, and Dilute to 25ml with pure water.

[0032] (2) Take 60 mg of raw whey protein, put it in a hydrolysis bottle, add 5 ml of 6 mol / L hydrochloric acid to seal it, hydrolyze it at 100°C for 5 hours, take 1 ml of the hydrolyzed solution, adjust the pH to 7.0, and dilute to 25 ml with ultrapure water.

[0033] (3) Add 0.7ml of boric acid buffer solution and 0.3ml of derivatization reagent to the sample and blank treatment solution obtained from step (1) and step (2), and mix well. Buffer and 0.1mL 3-mercaptopropionic acid, derivatized at 25°C for 18min in the dark.

[0034](4) The derivatized sample liquid is subjected to reverse high-performance liquid chromatography analysis, the chromatographic column is Elite C18, and the chromatographic column p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com