Method for intelligently controlling temperatures of furnaces and kilns

A technology of temperature control and intelligent control, which is applied to furnace control devices, furnaces, rotary drum furnaces, etc., can solve problems such as temperature lag, poor control accuracy stability, and slow reaction speed of coal combustion, so as to achieve coal consumption reduction and temperature control. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the original composition of the conventional well-known structure is not illustrated or shown in the figure.

[0030] Such as Figure 1-4 As shown, the method for intelligently controlling furnace temperature and the method for intelligently controlling furnace temperature disclosed in this embodiment includes the following steps:

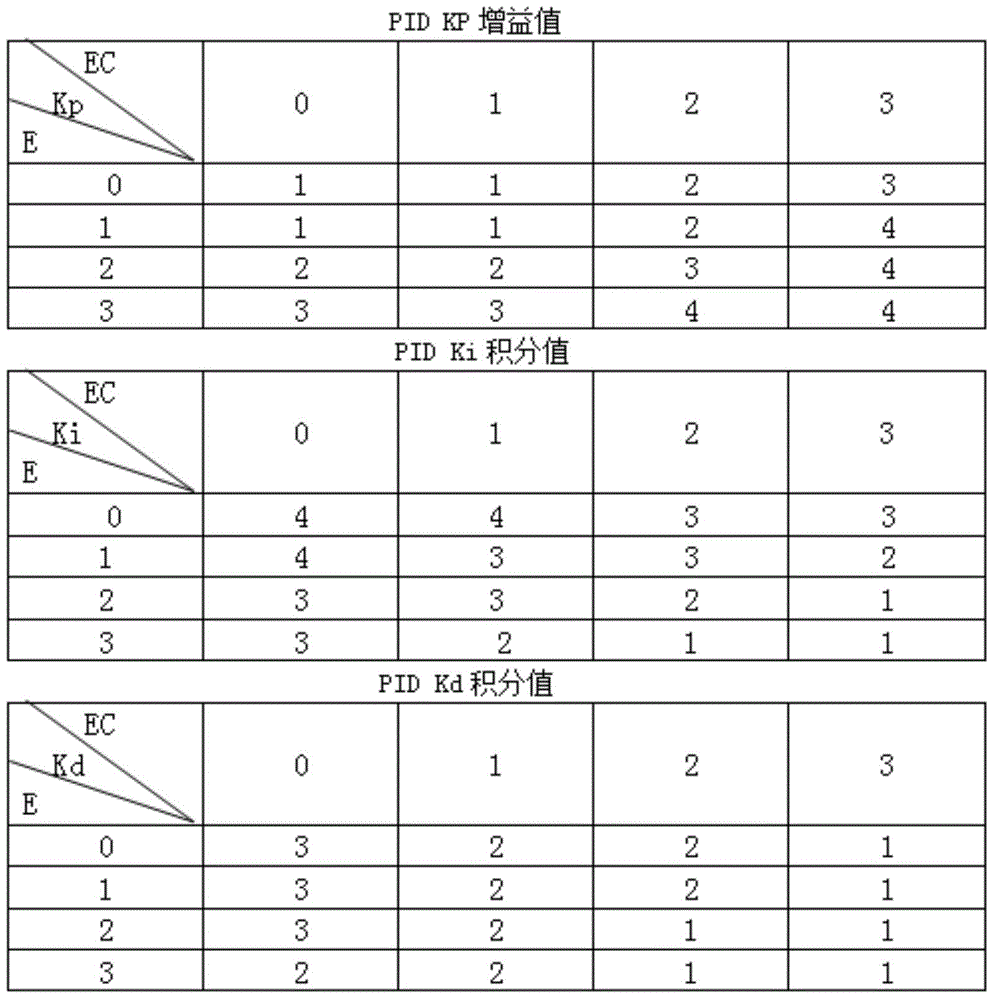

[0031] (1) Set up the rotary kiln temperature control subsystem and the decomposition furnace control subsystem; the rotary kiln temperature control subsystem and the decomposition furnace control subsystem are based on the same control platform, including the PID calculation module and the signal feedback module, and through the data statistics interface And the display window realizes variable adjustment, detection and real-time monitoring.

[0032] (2) Rotary kiln temperature control: Set the PID algorithm temperature setting module through the rotary kiln temperature control subsystem, obtain the PID setting temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com