Method for enhancing acid pickling efficiency of stainless steel tubes

A stainless steel tube and pickling technology, applied in the field of stainless steel tube pickling, can solve the problems of insufficient pickling, easy to produce dead corner pickling, affecting the pickling effect, etc., to enhance environmental benefits, reduce acid mist emissions, and enhance pickling. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Take the 50,000 tons stainless steel seamless steel pipe pickling system of Taiyuan Iron and Steel Co., Ltd. as an example to illustrate the present invention:

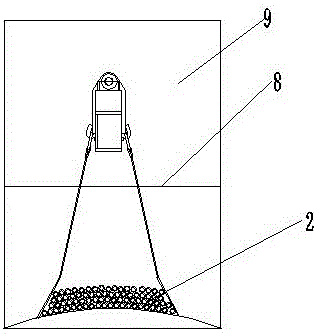

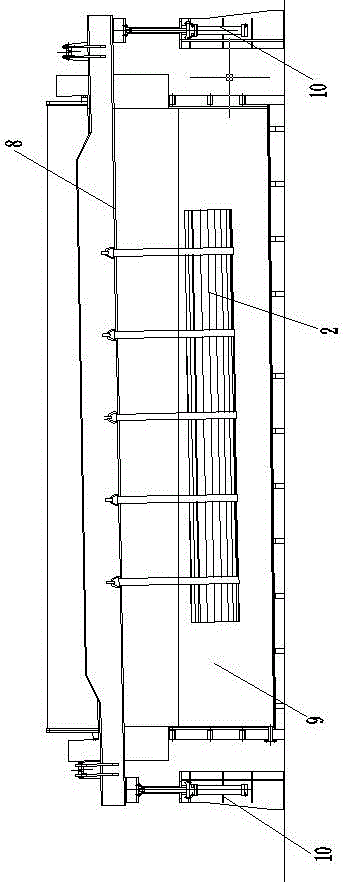

[0029] First transform the pickling tank equipment: the bottom of the pickling tank is set into an arc, and the arc at the bottom of the arc is 25 to 40 degrees; the acid tank both sides adopt movable support devices; There is a hydraulic cylinder, and the stainless steel pipe in the acid tank is adjusted to move up and down through the hydraulic cylinder.

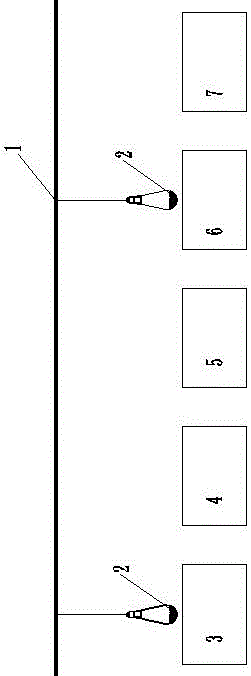

[0030] Use the crane track 1 to lift the bundled stainless steel pipes 2 and send them to the arc-shaped bottom of the pickling tank. After the tank cover is sealed, acid solution is added for pickling. During the pickling process, the movable supporting devices on both sides of the acid tank start to move. At the end of the pickling, the acid liquid in the acid tank is automatically emptied. After the tank cover is opened, the steel pipe is lifted by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com