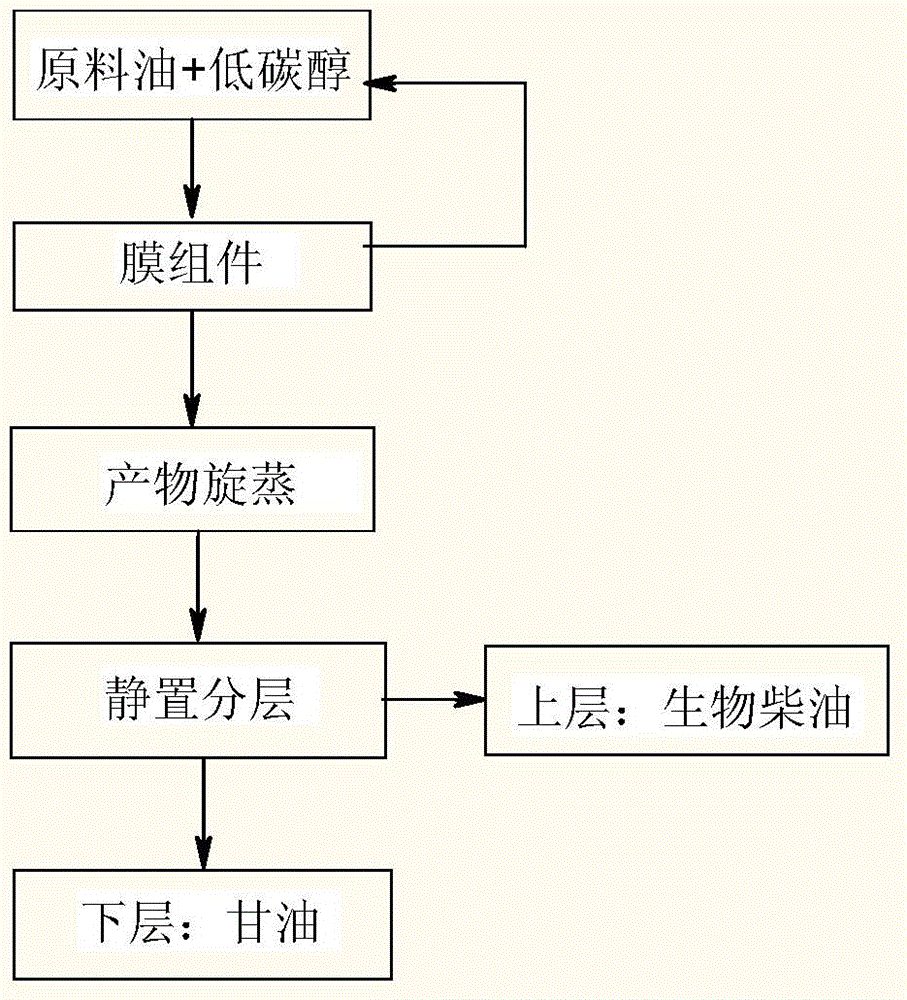

Hybrid catalytic membrane reactor and method for preparing biodiesel by using same

A technology of hybrid catalytic membrane and biodiesel, which is applied in the fields of biofuel, petroleum industry, fatty acid esterification, etc., can solve the problems of difficult recycling of catalyst inorganic alkali, high price of immobilized enzyme, and non-reusable enzyme membrane, etc. Achieve high raw material utilization efficiency, low production cost, and solve the effect of environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

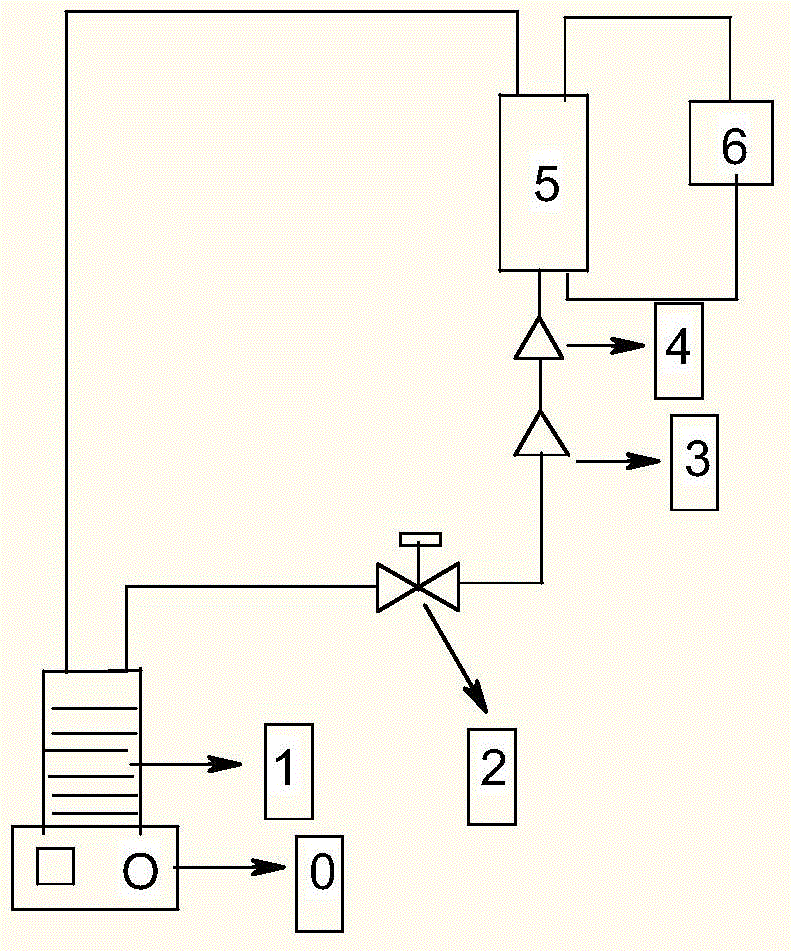

[0035] according to figure 2 Connect the relevant components and devices, first add 50g of raw material oil and 75g of methanol to the storage tank 1, turn on the constant temperature magnetic stirrer 0, heat the temperature in the storage tank to 40°C, turn on the constant temperature water bath 6 to make the circulating water temperature 40°C . Then turn on the circulating pump 2, control the reading of the pressure gauge to 0.2MPa, and the airspeed to 0.42m 3 / h (the volume of the reaction material passed by the circulating pump per unit time), starting from the feed oil and methanol entering the membrane module, the reaction time is 10h, and the calculated biodiesel yield is 88.3% after the reaction.

Embodiment 2

[0037] according to figure 2 Connect the relevant components and devices, first add 50g of raw material oil and 125g of methanol to the storage tank, turn on the constant temperature magnetic stirrer, heat to the temperature in the storage tank is 60°C, turn on the constant temperature water bath to make the circulating water temperature 60°C. Then turn on the circulation pump, control the reading of the pressure gauge to 0.6MPa, and the airspeed to 1.5m 3 / h, counting from the time when raw oil and methanol enter the membrane module, the reaction time is 30h, and the calculated biodiesel yield is 95.2% after the reaction.

Embodiment 3

[0039] according to figure 2Connect the relevant components and devices, first add 50g of raw material oil and 200g of ethanol to the storage tank, turn on the constant temperature magnetic stirrer, heat to the temperature in the storage tank to 60°C, turn on the constant temperature water bath to make the temperature of the circulating water to 60°C. Then turn on the circulating pump, control the reading of the pressure gauge to 0.4MPa, and the airspeed to 0.96m 3 / h, counting from the time when raw oil and methanol enter the membrane module, the reaction time is 40h, and the calculated biodiesel yield is 97.2% after the reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com