Spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis

A biomass pyrolysis and screw feeder technology, used in the preparation of biofuels, liquid hydrocarbon mixtures, special forms of dry distillation, etc., can solve problems such as clogging, high temperature carbonization, etc. The effect of controllable and safe feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

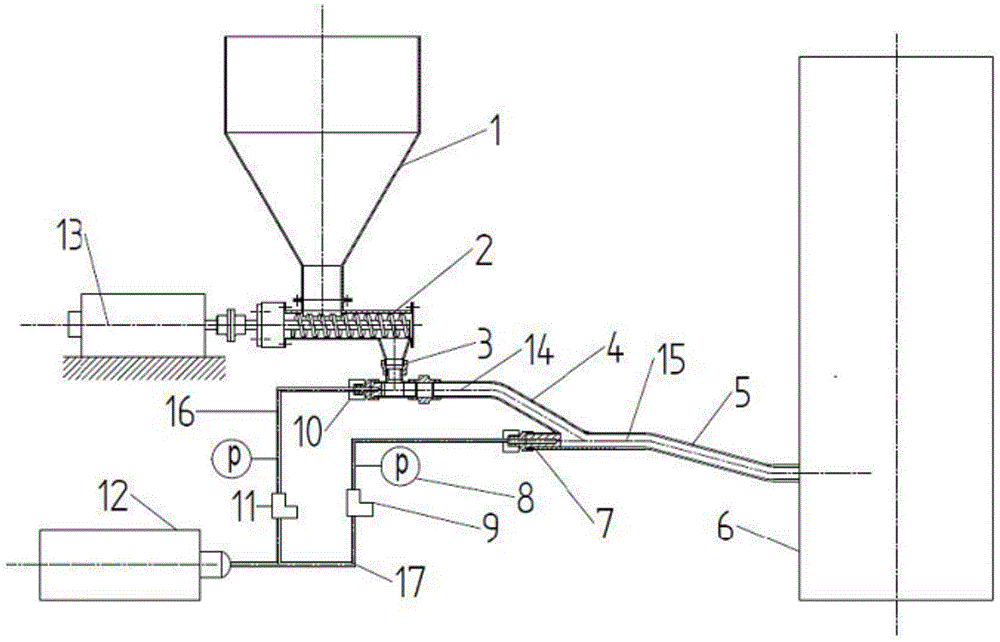

[0015] The spiral-pulse pneumatic mixing feeder for mobile biomass pyrolysis proposed by the present invention has a structure such as figure 1 As shown, it includes a speed regulating motor 13, a hopper 1, a screw feeder 2, a first inclined feeding pipe 4, a second inclined feeding pipe 5, a primary solenoid valve 11, a secondary solenoid valve 9, and a primary nozzle 10 , secondary nozzle 7 and carrier gas bottle 12. The output shaft of the speed-regulating motor 13 is connected with the rotating shaft of the screw feeder 2, the bottom of the hopper 1 is connected with the feed port of the screw feeder 2, and the discharge port of the screw feeder 2 is connected with the upper conveying port through the transition joint 3. The feed pipe 14 is connected, and one end of the upper feed pipe 14 is provided with a first-stage nozzle 10, and the first-stage nozzle 10 is connected with the carrier gas bottle 12 through the first air pipe 16, and the first air pipe 16 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com