Anti-skid feeding box capable of adjusting feeding amount

A technology of feeding box and feeding amount, applied in the direction of nuts, connecting components, threaded fasteners, etc., can solve the problems of low stability, feeding adaptation, and inability to effectively prevent the material from retreating, so as to prevent the material from retreating. , Guarantee the accuracy, increase the effect of feeding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

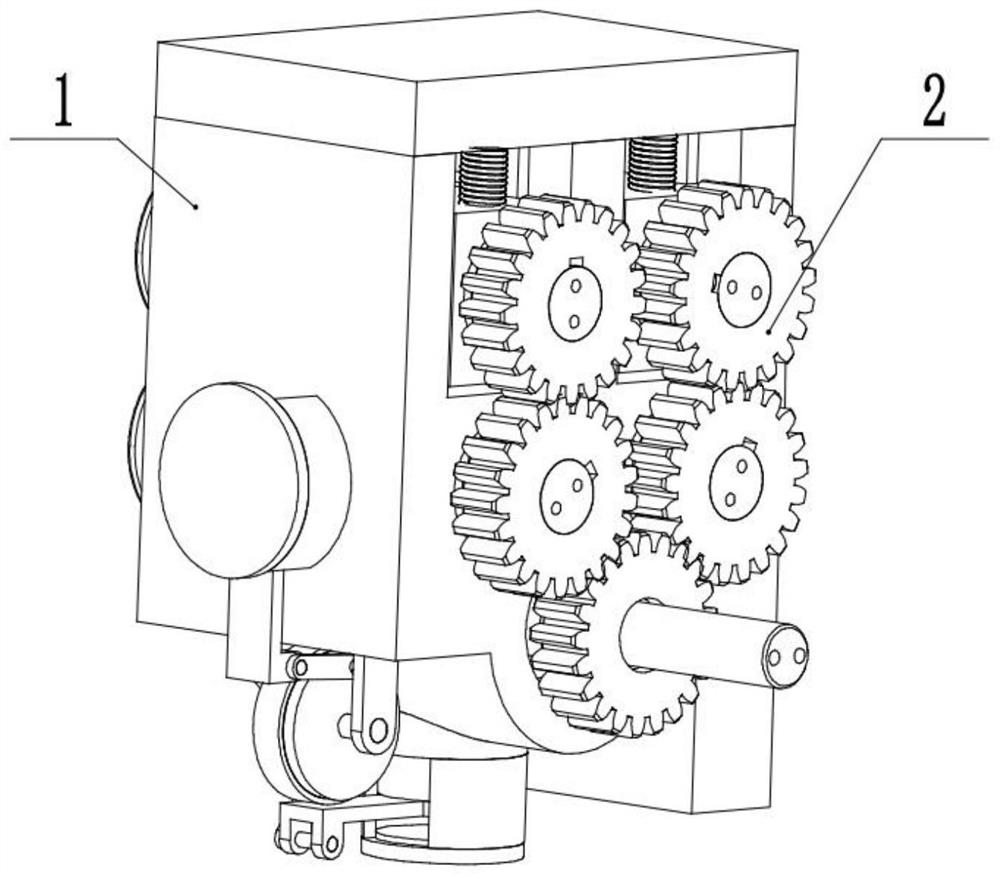

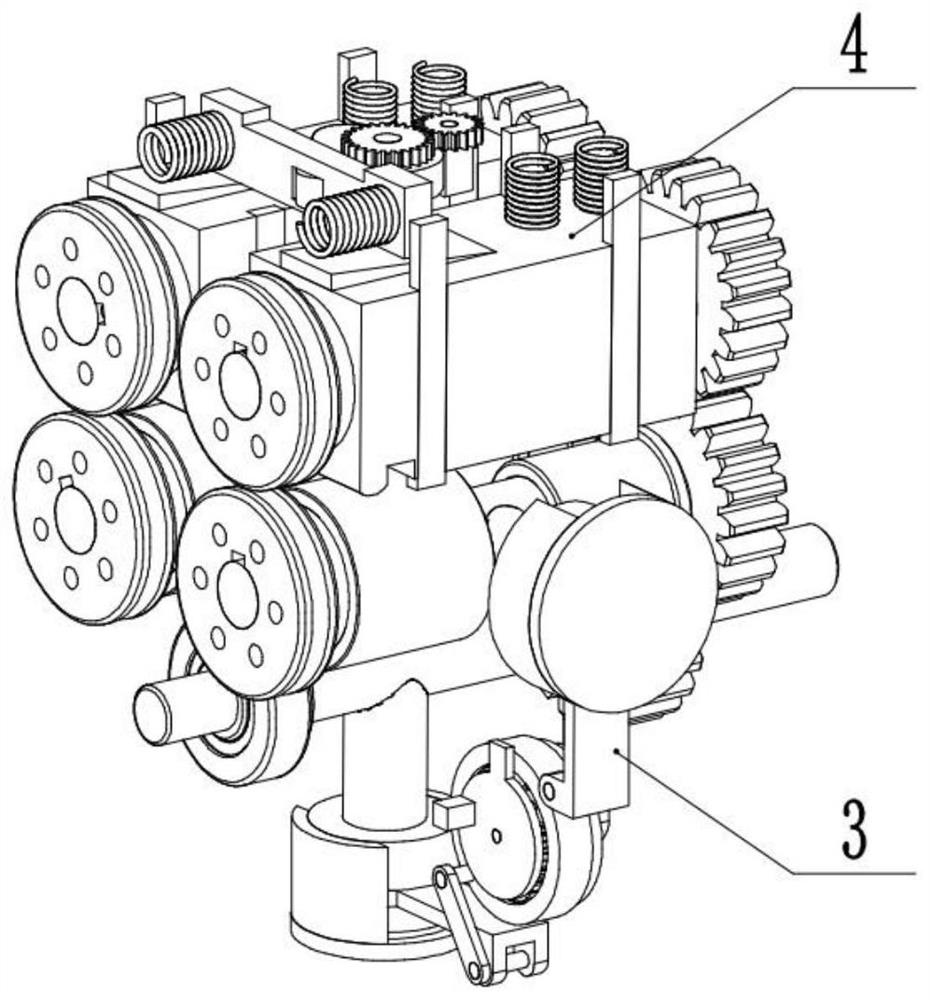

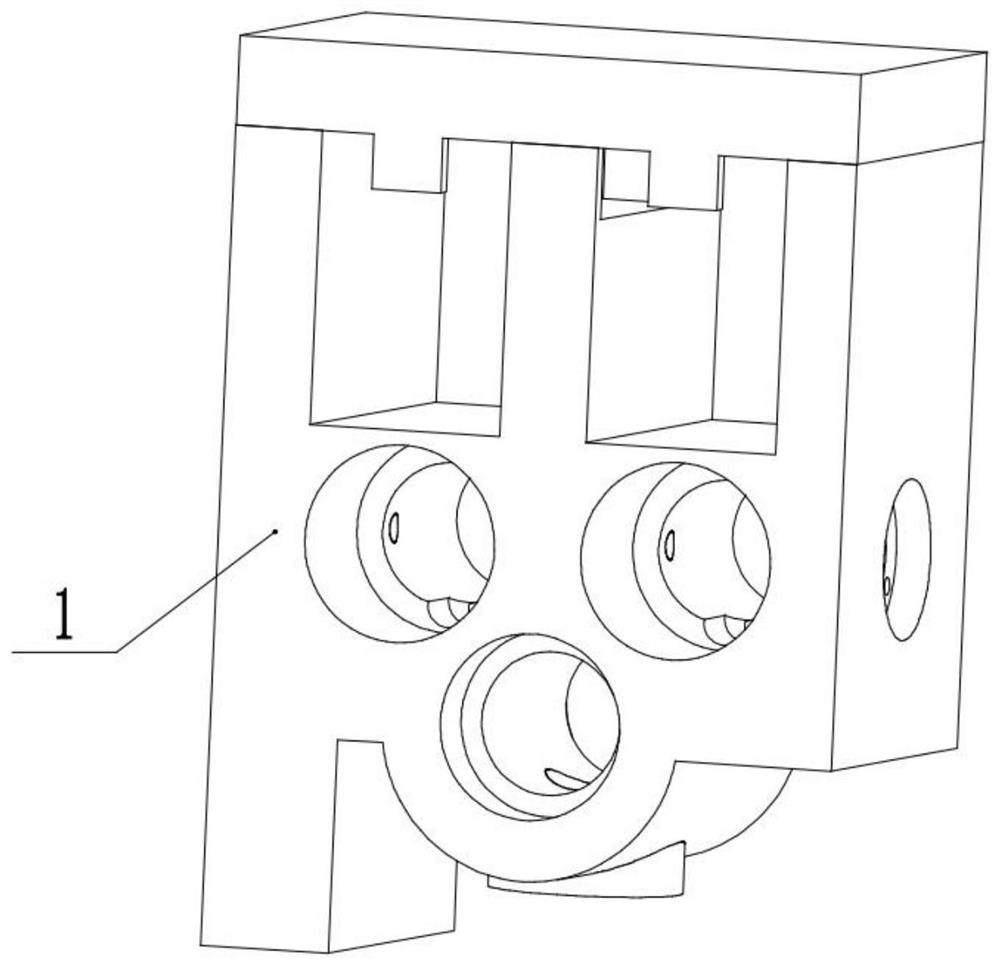

[0022] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 In the shown non-slip feeding box that can adjust the feeding amount, the feeding mechanism 2 is arranged on the feeding box 1, the anti-slip mechanism 3 is fixedly installed on the feeding box 1, and the adjusting mechanism 4 is fixedly installed on the feeding box 1 superior.

[0023] Feeding mechanism 2, wherein driving shaft 202 is connected with motor, and driving shaft 202 is installed on the feed box 1 in rotation, and driving gear 201 is fixedly installed on driving shaft 202, and driving gear 201 and lower feed gear 204 are meshed and installed. Material gear 204 is fixedly installed on one end of lower feeding shaft 203, and the other end of lower feeding shaft 203 is fixedly installed with lower feeding wheel 207, and lower feeding shaft 203 is rotatably installed on the feed box 1, and lower feeding gear 204 and The upper feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com