High-bearing low-density low-odor high-rebounding foam material and preparing method thereof

A foam material and low-density technology, which is applied in the field of polyurethane, can solve the problems of increasing the content of harmful substances in polyurethane foam materials, increasing raw material costs and process costs, and increasing odor and harmful gases, so as to reduce VOC harmful substances and odors and improve foam quality. Bearing capacity, effect of reducing foam density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The high-resilience foam material with high load bearing, low density and low odor is prepared as follows:

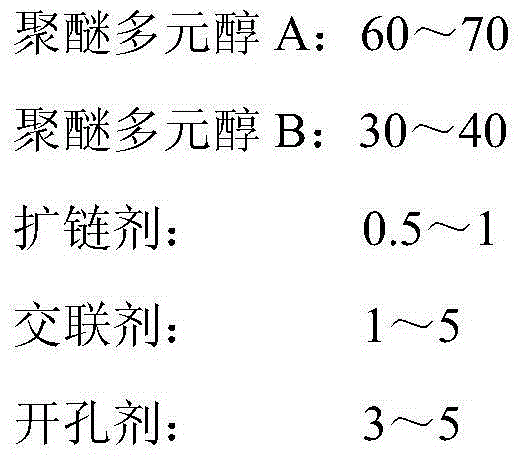

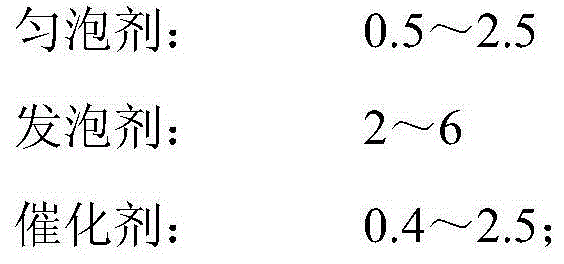

[0031] A component

[0032]

[0033]

[0034] Group B is divided into:

[0035] TDI(80 / 20): 60

[0036] PM-200: 40

[0037] A component: Put the measured YEP-4700 and YNW-2800 into the reaction kettle at room temperature and stir evenly, then add the measured DEG, DEOA, DK-12, DC6070, H 2 O, A-1, A-33, C-225 and 141B, stir for 0.5h, take samples for foaming test, the foaming is normal, and store in barrels sealed.

[0038] Preparation of component B: Add measured amounts of TDI and PM-200 into the reaction kettle at room temperature, stir for 0.5 h, take a sample to detect NCO% = 41.4, and store in a sealed barrel.

[0039] When in use, mix components A and B at room temperature according to the mass ratio of A:B=1:0.44 and pour them into a mold to obtain a foam material.

Embodiment 2

[0041] The high-resilience foam material with high load bearing, low density and low odor is prepared as follows:

[0042] A component

[0043]

[0044] Group B is divided into:

[0045] TDI(80 / 20): 40

[0046] DG-5412: 60

[0047] Component A: Put the measured YEP-4700 and YNW-2800 into the reaction kettle at room temperature and stir evenly, then add the measured 1,4-BG, DEOA, DK-12, L-3150, H 2 O, A-1, A-33, P-225 and 141B, stir for 0.6h, take samples for foaming test, the foaming is normal, and store in barrels sealed.

[0048] Preparation of component B: Add the measured amount of TDI and DG-5412 into the reaction kettle at room temperature, stir for 0.6h, take a sample for detection of NCO%=35, and store in a sealed barrel.

[0049] When in use, mix components A and B at room temperature according to the mass ratio of A:B=1:0.5 and pour them into a mold to obtain a foam material.

Embodiment 3

[0051] The high-resilience foam material with high load bearing, low density and low odor is prepared as follows:

[0052] A component

[0053]

[0054] Group B is divided into:

[0055] TDI(80 / 20): 50

[0056] PM-200: 30

[0057] DG-5412: 20

[0058] Component A: Put the measured YEP-4700 and YNW-2800 into the reaction kettle at room temperature and stir evenly, then add the measured DPG, TEA, DK-12, DC6070, H 2 O, A-1, A-33, A-300 and 141B, stir for 0.8h, take samples for foaming test, the foaming is normal, and store in barrels sealed.

[0059] Preparation of component B: Add the measured amount of TDI, PM-200, and DG5412 into the reaction kettle at room temperature, stir for 0.8h, take a sample to detect NCO%=38.65, and store it in a sealed barrel.

[0060]When in use, mix components A and B at room temperature according to the mass ratio of A:B=1:0.52 and pour them into a mold to obtain a foam material.

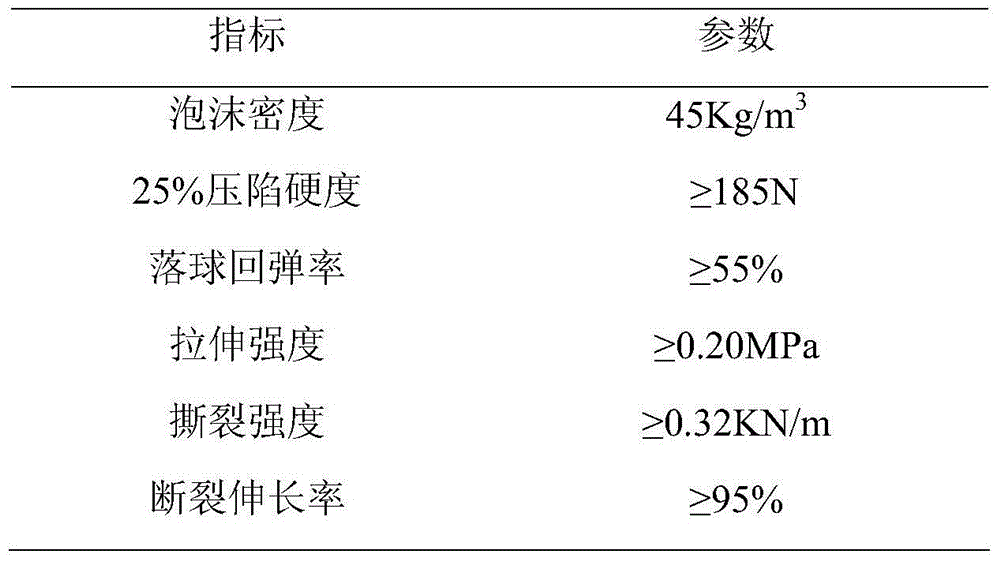

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com