Preparation device and preparation method of high-concentration and high-stability hydrogen-rich water

A high stability, preparation device technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of insufficient hydrogen content and the stability of hydrogen concentration in hydrogen-rich water No high-level problems, achieve the effect of low equipment requirements, easy promotion, and high hydrogen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

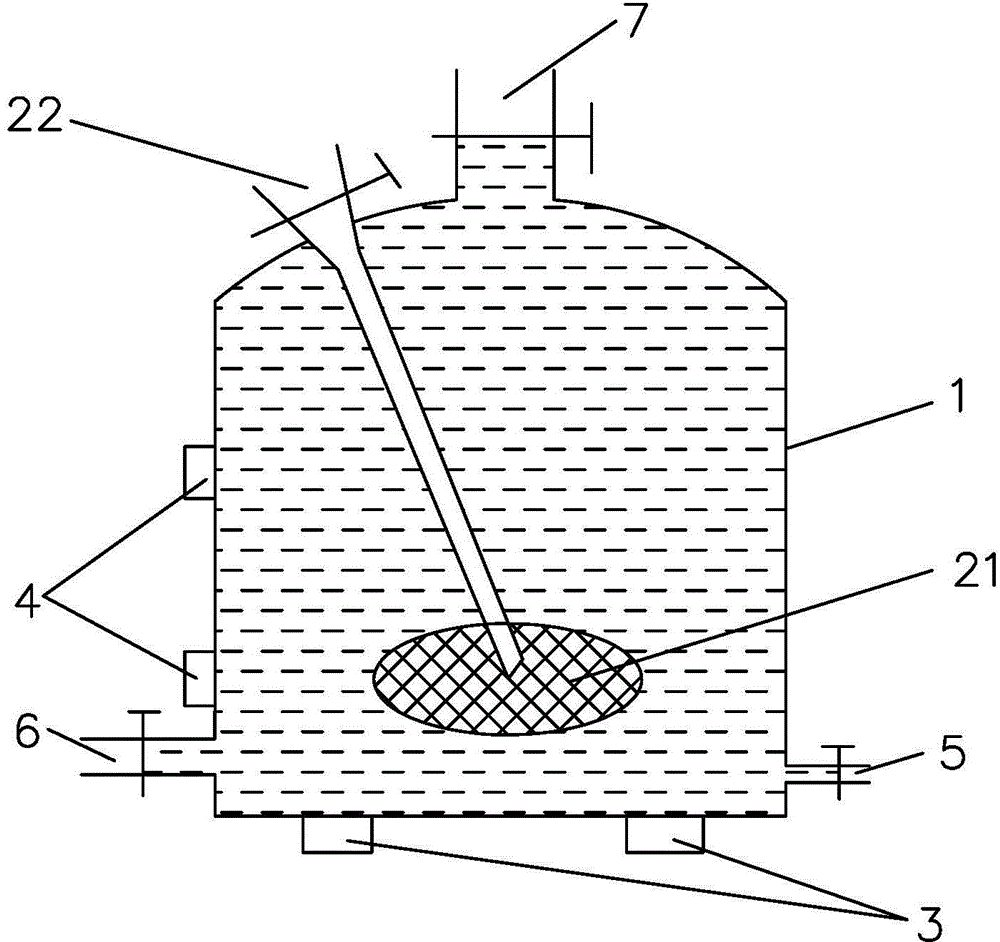

[0034] Such as figure 1 As shown, the hydrogen-rich water preparation device provided in this implementation includes a water storage tank 1, a magnesium powder bag 21, an inlet 22, an ultrasonic generator 1 3 and an ultrasonic generator 2 4.

[0035] The water storage tank 1 is an airtight cylindrical tank body, the side wall is provided with a water outlet 5 and a water inlet 6, and the top is provided with a vacuum interface 7, and the water outlet 5, the water inlet 6 and the vacuum interface 7 are all provided with valves. The water outlet 5 is connected with the filtering device or directly with the packaging bag. The water inlet 6 is connected with a water supply device for drinking water meeting national standards. The vacuum interface 7 is connected with a vacuum pump through a pipeline.

[0036]The hydrogen source is magnesium powder. The magnesium powder enters the water storage tank 1 through the entrance 22, and is packed with a water-permeable film to form a m...

Embodiment 2

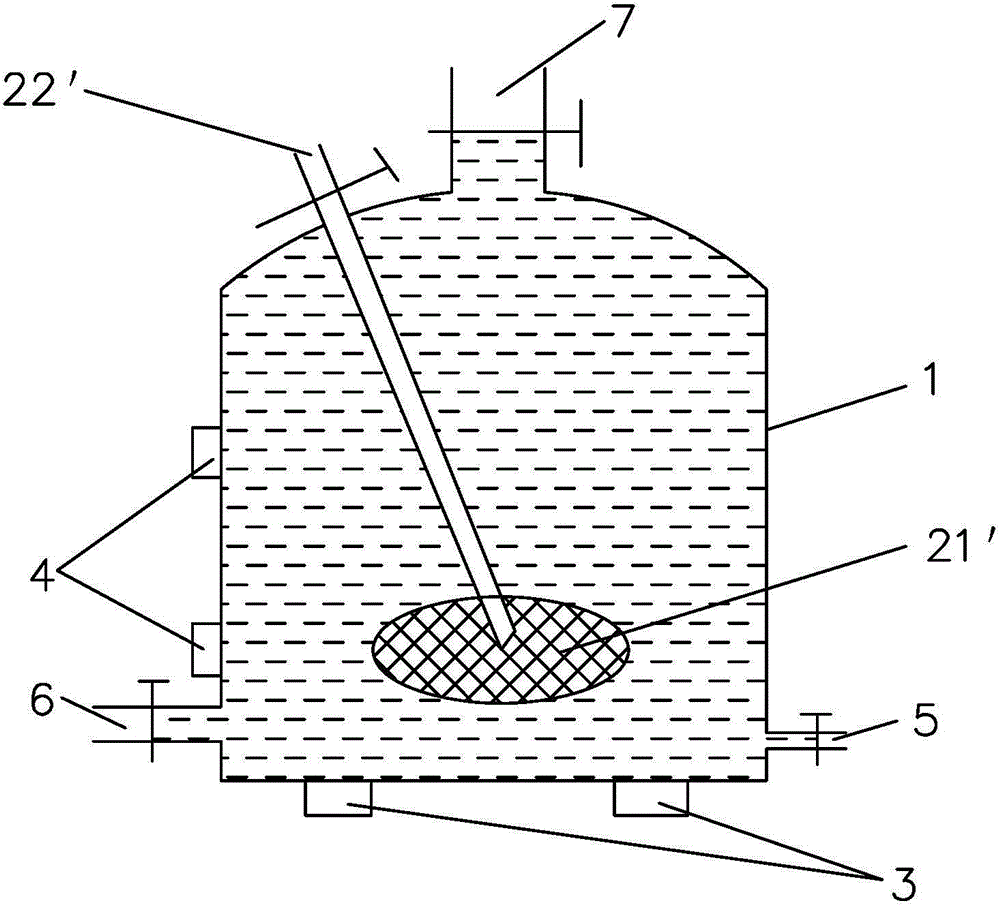

[0039] Such as figure 2 As shown, the hydrogen-rich water preparation device provided in this implementation includes a water storage tank 1 , an aeration head 21 ′, an inlet 22 ′, an ultrasonic generator 1 3 and an ultrasonic generator 2 4 . ,

[0040] The water storage tank 1 is an airtight cylindrical tank body, the side wall is provided with a water outlet 5 and a water inlet 6, and the top is provided with a vacuum interface 7, and the water outlet 5, the water inlet 6 and the vacuum interface 7 are all provided with valves. The water outlet 5 is connected with the filtering device or directly with the packaging bag. The water inlet 6 is connected with a water supply device for drinking water meeting national standards. The vacuum interface 7 is connected with a vacuum pump through a pipeline.

[0041] In the present invention, the hydrogen source is a structure mainly composed of a hydrogen storage tank, a pressure reducing valve, a flow valve, an air guide pipe and ...

Embodiment 3

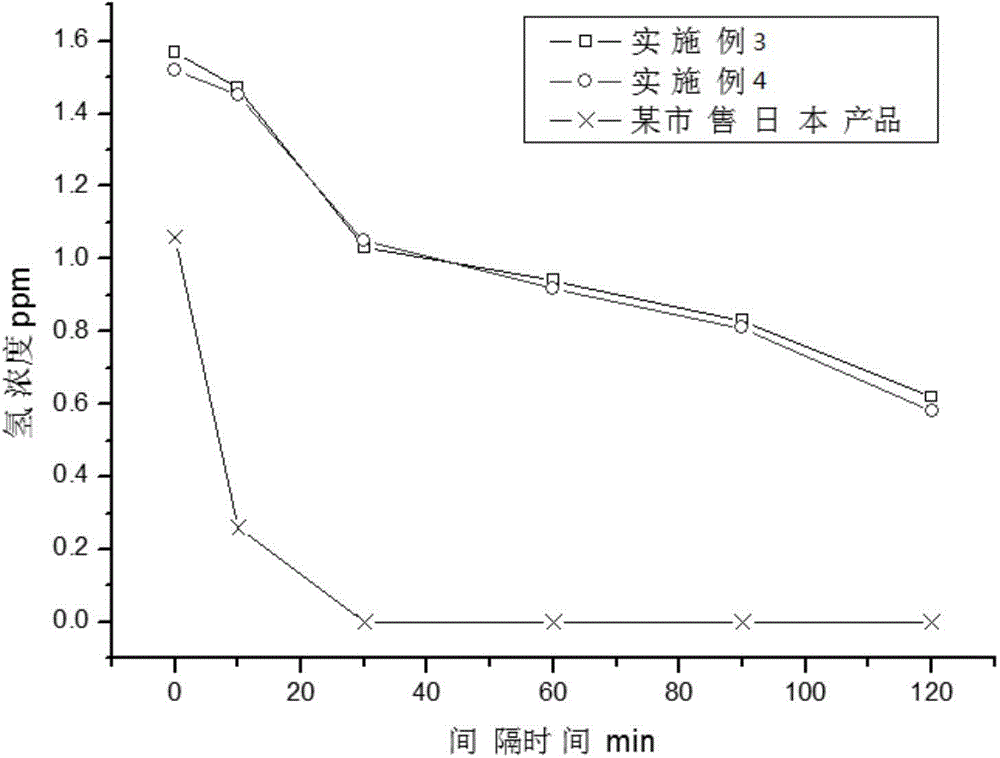

[0047] Inject 1000g of pure drinking water into the water storage tank 1 through the water inlet 6, turn on the ultrasonic generating device 3 and / or the ultrasonic generating device 4, and degas through the vacuum interface 7 for 2 hours, and the vacuum degree is -0.05MPa. Close the ultrasonic generating device 3 and / or the ultrasonic generating device 4, put 1g of magnesium powder with a particle size of 100 mesh as the hydrogen source of magnesium chemical reduction hydrogen production, and put the magnesium powder into the water storage tank 1 through the entrance 21, and use a permeable membrane The packaging forms a magnesium powder bag 22, generates hydrogen fine bubbles, seals the water storage tank 1, and turns on the ultrasonic generator 3 and / or ultrasonic generator 4 at the same time, and mixes gas and water for 1 hour, and the fine bubbles are turned into microscopic bubbles by ultrasonic cavitation. Nano-bubbles, the diameter of micro-nano bubbles is 0.1 μm to 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com