A multi-layer corrugated cardboard production line

A corrugated board and production line technology, applied in the direction of layered products, lamination, lamination devices, etc., can solve the problems of reduced team output, customer returns, slow starch gelatinization, etc. The effect of speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment.

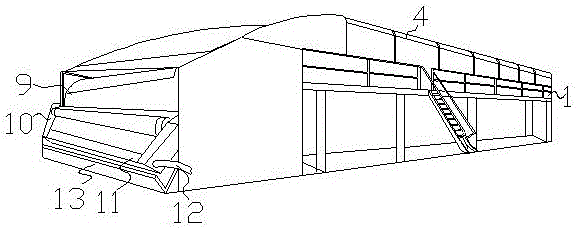

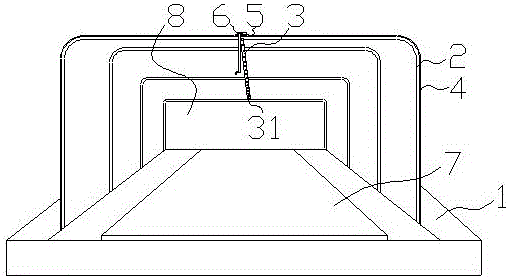

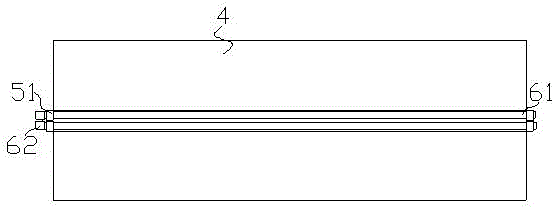

[0019] Depend on Figures 1 to 5 It can be seen that a multi-layer corrugated cardboard production line includes a paper feeding bridge 1, an arch rod 2, a spray pipe 3 and a thermal insulation film 4. Arch rods, wherein the head and tail of the paper feeding bridge are respectively provided with an arch rod, the top of the arch rod is connected to form a smooth curved surface, the top of the arch rod is provided with a flat beam 5 in the middle, and the thermal insulation film is a heat insulation film or plastic film, and the thermal insulation film is made of a flat plate The beam is laid on both sides, the fixed end of the thermal insulation film is fixedly connected with the flat beam, the movable end of the thermal insulation film is flexibly connected with both sides of the paper feeding bridge, and the thermal insulation film covers the entire paper feeding bridge to form a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com