Control method of ejection mechanism of special single-station foaming machine for refrigerators

A technology of ejection mechanism and control method, which is applied in the field of control of the ejection mechanism of a single-station foaming machine for refrigerators, can solve the problems of large investment and difficulty in manufacturers, achieve high transmission efficiency, good action consistency, and improve foaming quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

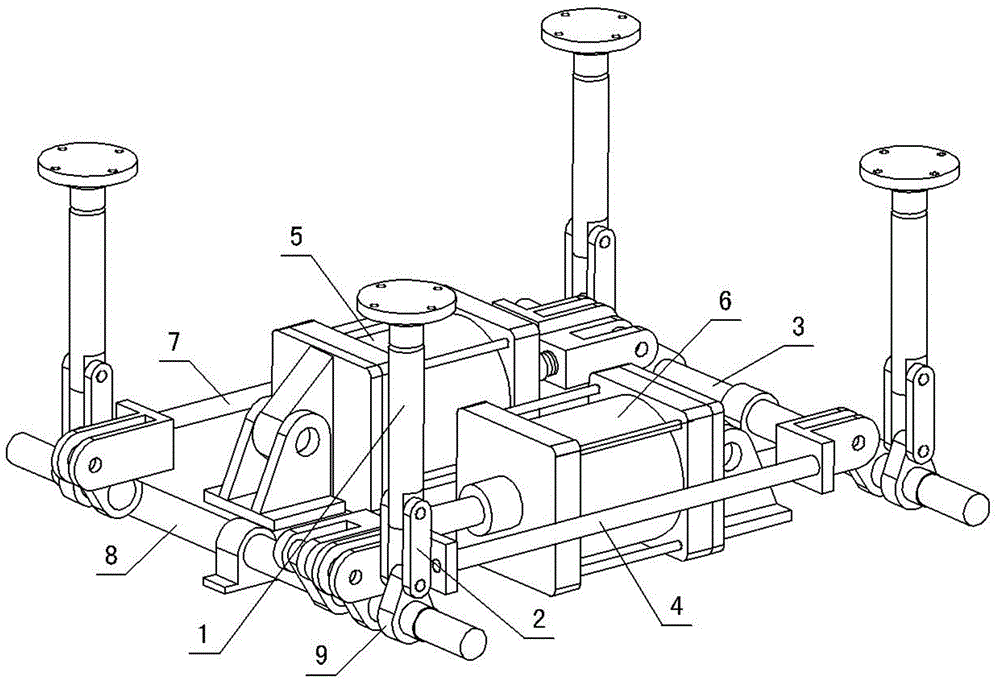

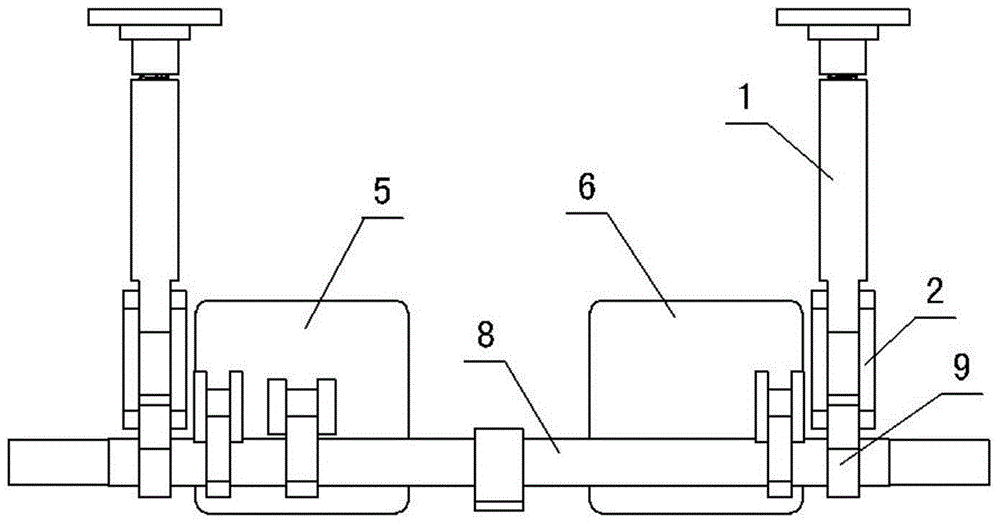

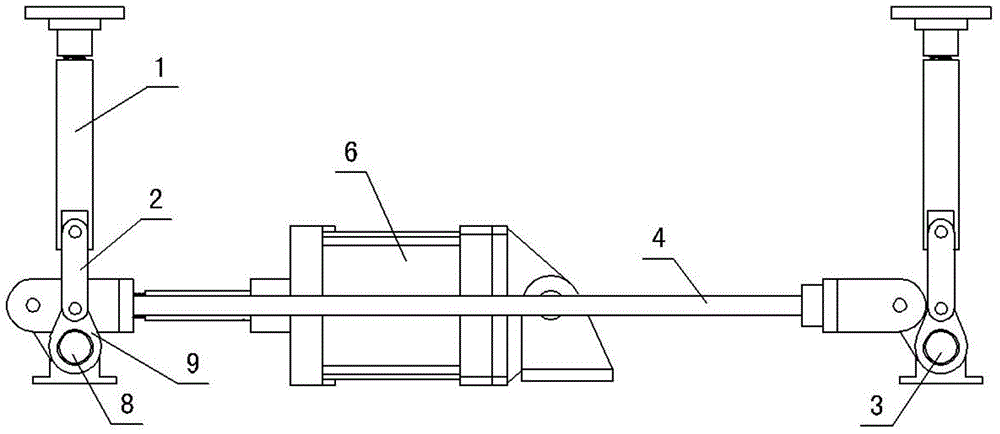

[0021] see figure 1 , figure 2 , image 3 with Figure 4 , the characteristics of the ejection mechanism of the refrigerator single-station foaming machine in this embodiment are:

[0022] The front connecting frame rod 4, the rear connecting frame rod 7, the left camshaft 8, and the right camshaft 3 are hinged to form a parallel four-bar mechanism distributed in a rectangular frame on the plane. The parallel four-bar mechanism makes each ejector rod move well. consistency.

[0023] On the left camshaft 8 and the right camshaft 3, cams are respectively arranged one after the other. Taking the cam 9 arranged on the front side on the left camshaft 8 as an example, the cam 9 and the connecting rod 2 connected with the cam 9 , the ejector rod 1 that is connected with the connecting rod 2, and the foaming special machine bottom plate that is fixedly arranged on the ejector rod 1 constitutes a slider crank mechanism; in addition, the cam that is arranged on the rear side on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com