Assembling device and assembling method of rotary fan cover

An assembly device and fan cover technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult positioning, long assembly line length, and rising renovation costs, and achieve simple and easy distance control, compact overall structure, The effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

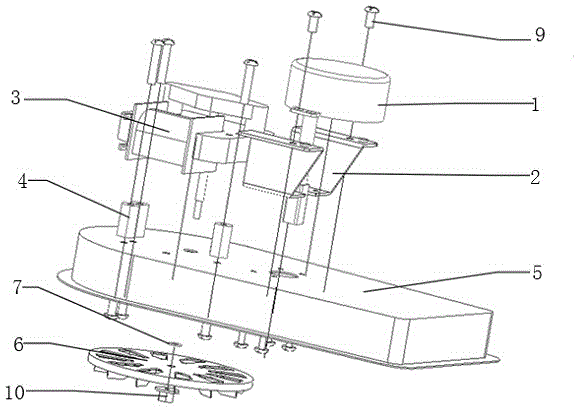

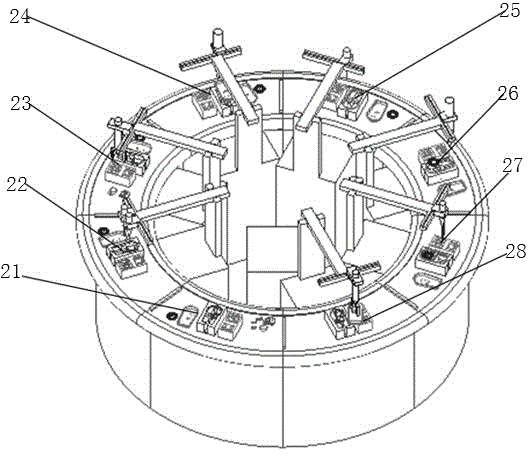

[0019] Such as figure 1 , figure 2 As shown, the assembly device of the rotary fan cover of the present invention includes a rotating mechanism 11, a transfer mechanism 12, an automatic assembly mechanism 13, a clamp system 14 and a controller 15. The rotating mechanism converts stations by rotating motion, and the transfer mechanism can The parts to be assembled are placed in the assembly position. The automatic assembly mechanism can assemble the parts to be assembled together. The fixture system cooperates with the automatic assembly mechanism for assembly, and the controller is used to control the assembly speed. The transfer mechanism, the automatic assembly mechanism, and the controller are distributed annularly along the rotating mechanism; the clamp system is equally distributed on the rotating mechanism according to the number of processes. The invention is used for the assembly of the fan cover, and the assembly process is similar to the linear assembly line.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com