Automotive rear bridge torsion beam hinged lining assembling and disassembling tool

A technology for automobile rear axles and torsion beams, which is applied in the field of disassembly and assembly tools for torsion beam hinged bushings of automobile rear axles. It can solve the problems of lack of rear axle bushing replacement tools, bulky presses, and unsuitable use, and achieve simple structure. , Small size, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

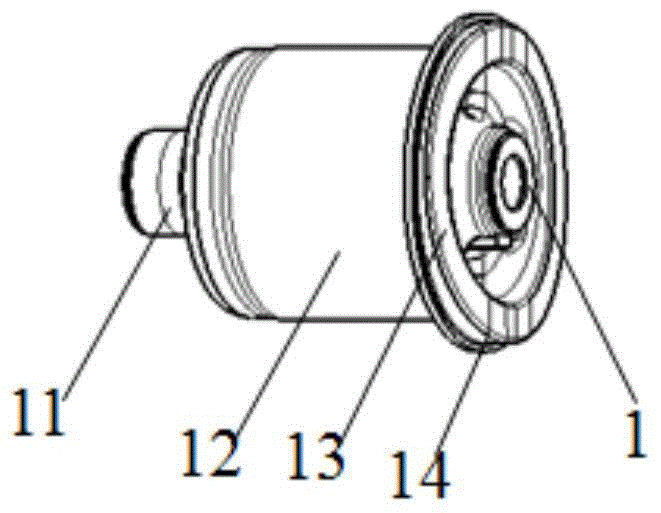

[0034] Such as figure 1 Shown is the hinged bushing 1 structure, figure 2 It is a hinged casing 2 structure, and the hinged bushing 1 is divided into three parts: the hinged inner cylinder 11, the hinged outer cylinder 12, and the rubber body 13. Among them, the hinged inner cylinder 11 and the hinged outer cylinder 12 are made of steel, and the rubber body 13 is vulcanized. Connect the hinged inner cylinder 11 and the hinged outer cylinder 12 to the hinged inner cylinder 11 and the hinged outer cylinder 12 as a whole, wherein the rubber body 13 extends outward from one end of the outer cylinder 12 to form a rubber outer edge 14, and the rubber outer edge 14 is from the inside to the outside. The outer step surface gradually descends, and the inner cylinder 11 at the other end of the outer cylinder 12 exceeds the end surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com