A kind of preparation method of fluorine removal adsorption material based on magnesite

An adsorption material, magnesite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve problems such as increased process, large bed resistance, and increased cost. Achieve the effects of easy operation, low cost of raw materials and equipment, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

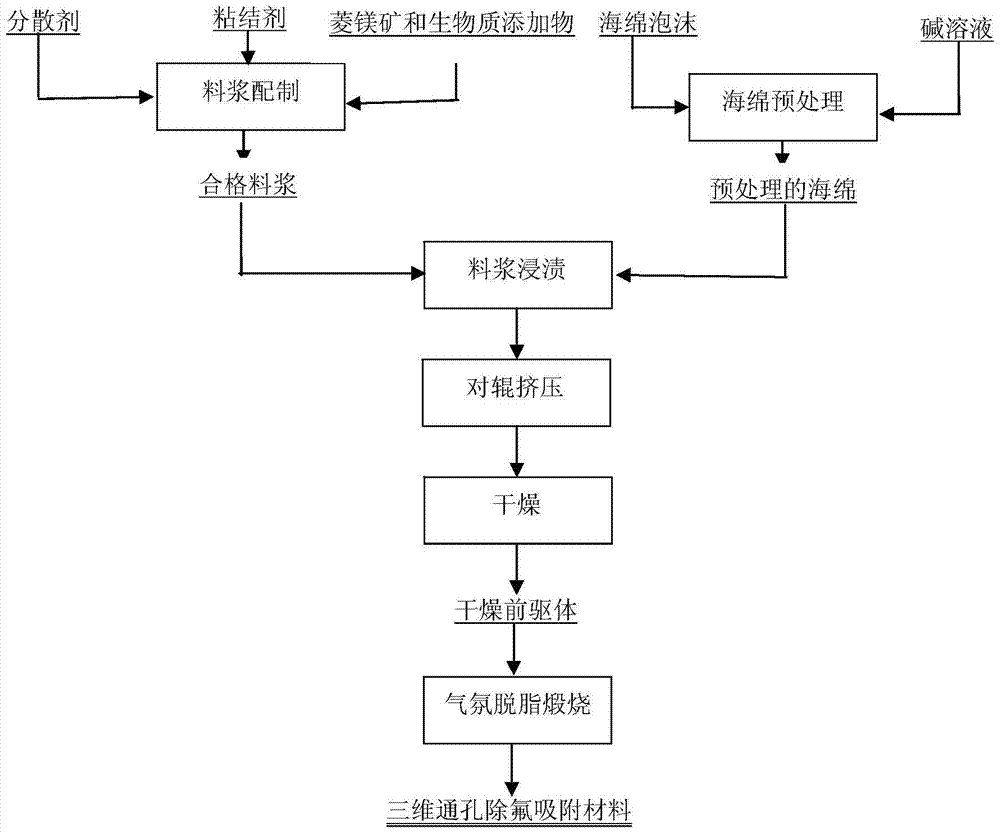

[0036] A preparation method of a three-dimensional through-hole structure defluorination adsorption material, according to figure 1 The technological process for preparing three-dimensional through-hole structure fluorine removal adsorption material.

[0037] The first step: powder raw material preparation

[0038] Using natural magnesite as raw material, the powder with a particle size of 1-10um is obtained by mechanical crushing, the magnesite powder and the corn flour with a particle size of 5um are mixed at a mass ratio of 85:15, and then added to ethanol and ball milled for 5 hours to obtain a mixture Powder, the mass ratio of the volume of ethanol to the mixed powder is 1:1, the unit is ml / g.

[0039] The second step: slurry preparation

[0040] Add the mixed powder obtained in the first step into the binder solution evenly while stirring to make a slurry, the stirring time is 1h, the mass content of the mixed powder in the slurry is 80%, and the binder solution is mad...

Embodiment 2

[0047] A preparation method of a three-dimensional through-hole structure defluorination adsorption material, according to figure 1 The technological process for preparing three-dimensional through-hole structure fluorine removal adsorption material.

[0048] The first step: powder raw material preparation

[0049]Using natural magnesite as raw material, the powder with a particle size of 1-10um is obtained by mechanical crushing, the magnesite powder and the corn flour with a particle size of 5um are mixed at a mass ratio of 80:20, and then added to ethanol and ball milled for 5 hours to obtain a mixture Powder, the mass ratio of the volume of ethanol to the mixed powder is 1:1, the unit is ml / g.

[0050] The second step: slurry preparation

[0051] Add the mixed powder obtained in the first step into the binder solution evenly while stirring to make a slurry, the stirring time is 1h, the mass content of the mixed powder in the slurry is 90%, and the binder solution is made...

Embodiment 3

[0058] A preparation method of a three-dimensional through-hole structure defluorination adsorption material, according to figure 1 The technological process for preparing three-dimensional through-hole structure fluorine removal adsorption material.

[0059] The first step: powder raw material preparation

[0060] Using natural magnesite as raw material, through mechanical crushing to obtain powder with a particle size of 10-20um, mix magnesite powder and rice husk with a particle size of 10um at a mass ratio of 90:10, then add them to ethanol and ball mill for 5 hours to obtain the mixture Powder, the mass ratio of the volume of ethanol to the mixed powder is 1:1, the unit is ml / g.

[0061] The second step: slurry preparation

[0062] Add the mixed powder obtained in the first step into the binder solution evenly while stirring to make a slurry, the stirring time is 1h, the mass content of the mixed powder in the slurry is 90%, and the binder solution is made of polyvinyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com