Control table of shell treatment system

A processing system and console technology, applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, other seating furniture, etc., can solve the problem that the seat cannot move forward and backward, and achieve the effect of good convenience and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the drawings and embodiments.

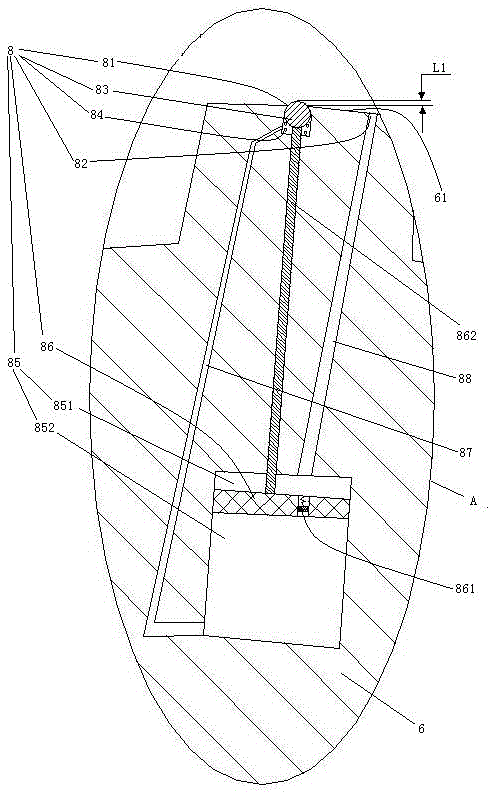

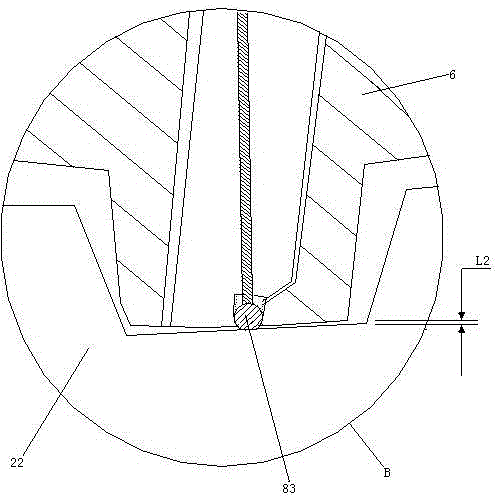

[0031] See figure 1 , A shell processing system console, including a seat 2, a rack 22, a braking mechanism 4, and a workbench 21 located in front of the seat. A balance roller 5 is provided below the front end of the seat 2. The balance roller 5 is connected to the seat 1 through a support rod 51. A walking gear 6 is provided below the rear end of the seat 2. The traveling gear 6 is connected to the axle 1. The axle 1 is connected to the seat 2 through a damping rod 9. The rack 22 meshes with the traveling gear 6. Several lubricating mechanisms 8 are provided in the traveling gear 6. The number of lubricating mechanisms 8 is equal to the number of teeth of the traveling gear 6. An anti-fall switch 7 is connected to the seat 2. The fall prevention switch 7 includes a housing 71 and two wiring pins 72. The housing 71 is made of insulating material. The fall preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com