Processing method of vine tea beverage

A processing method and technology for rattan tea, applied in the field of rattan tea beverage processing, can solve the problems of low acceptance of consumption finger, turbidity of tea soup, poor flavor quality, etc. The effect of increasing sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

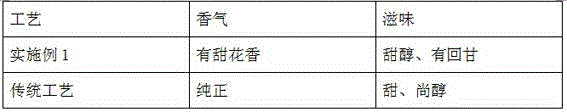

Embodiment 1

[0024] Raw materials: 20 kg of rattan tea, 6 kg of oolong tea, 3 kg of licorice and 3 kg of wolfberry. After crushing and screening, 16-40 meshes of broken tea are obtained. The hygienic indicators such as pesticide residues, heavy metals and microorganisms meet the relevant provisions of the national standards of the People's Republic of China.

[0025] Extraction: 32 kg of crushed tea obtained was extracted by low-temperature countercurrent extraction method to extract the active ingredients in the crushed tea, the extraction tea-water ratio was 1:50, the extraction temperature was 85°C, and the extraction time was 30 min. Extract 1500 L.

[0026] Compound enzyme treatment: The obtained extract was subjected to compound enzyme treatment, the amount of glucosidase added was 95g (1.1%), the amount of esterase added was 85g (1.0%), the amount of pectinase added was 53g (0.6%), and the amount of compound enzyme added The temperature was 45°C, and the enzymatic hydrolysis time wa...

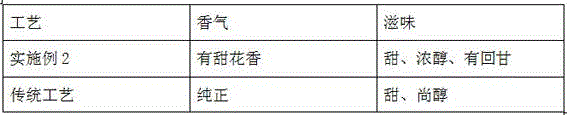

Embodiment 2

[0035] Raw materials: 18 kg of vine tea, 5 kg of oolong tea, 4 kg of licorice and 3 kg of wolfberry. After crushing and screening, 16-40 meshes of broken tea are obtained. The hygienic indicators such as pesticide residues, heavy metals and microorganisms meet the relevant provisions of the national standards of the People's Republic of China.

[0036] Extraction: 30 kg of the obtained broken tea was extracted with low temperature countercurrent extraction method to extract the active ingredients in the broken tea, the extraction tea water ratio was 1:30, the extraction temperature was 75°C, the extraction time was 50 min, and the tea with better flavor was obtained by filtration. Extract 900 L.

[0037] Compound enzyme treatment: The obtained extract was subjected to compound enzyme treatment, the amount of glycosidase added was 165g (2.0%), the amount of esterase added was 66 g (0.8%), the amount of pectinase added was 90g (1.1%), and the amount of compound enzyme The treatm...

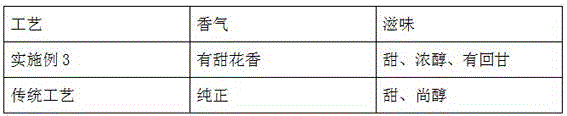

Embodiment 3

[0046] Raw materials: 15 kg of rattan tea, 7 kg of oolong tea, 6 kg of licorice and 2 kg of Chinese wolfberry. After crushing and screening, 16-40 meshes of broken tea are obtained. The hygienic indicators such as pesticide residues, heavy metals and microorganisms meet the relevant provisions of the national standards of the People's Republic of China.

[0047] Extraction: 30 kg of the obtained broken tea was extracted with low-temperature countercurrent extraction method to extract the active ingredients in the broken tea. The extraction tea-water ratio was 1:60, the extraction temperature was 65°C, and the extraction time was 40 min. Extract 1800 L.

[0048] Compound enzyme treatment: the obtained extract was subjected to compound enzyme treatment, the amount of glycosidase added was 25g (0.3%), the amount of esterase added was 180g (2.2%), the amount of pectinase added was 32g (0.4%), and the amount of compound enzyme The temperature was 50°C, and the enzymatic hydrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com