Hydraulic connecting bush, hydraulic connection, and hydraulic plug

A connecting sleeve and hydraulic technology, which is applied in the connection of packing seal with fluid pressure, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc., can solve the problems of forgetting support ring, wrong assembly, easy failure, etc., to achieve The effect of cost saving, elimination of assembly errors, and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

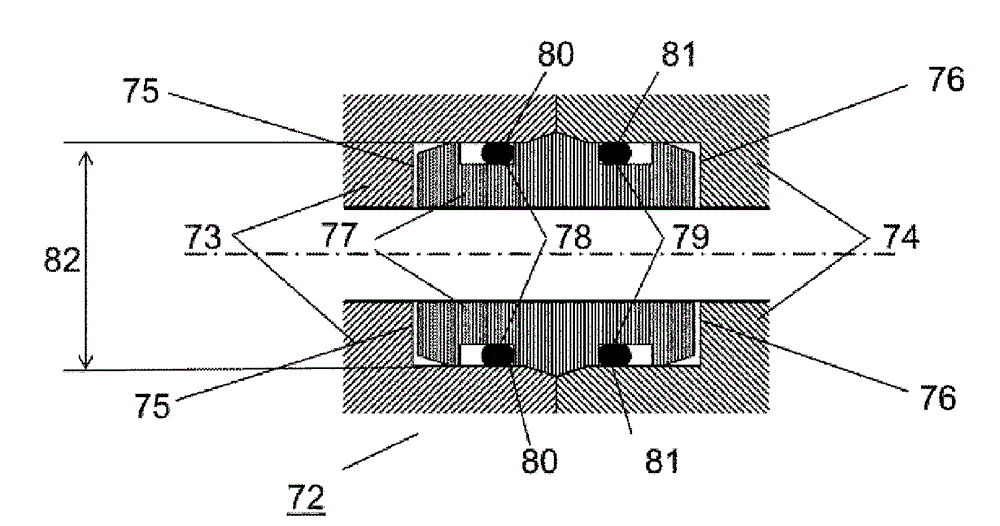

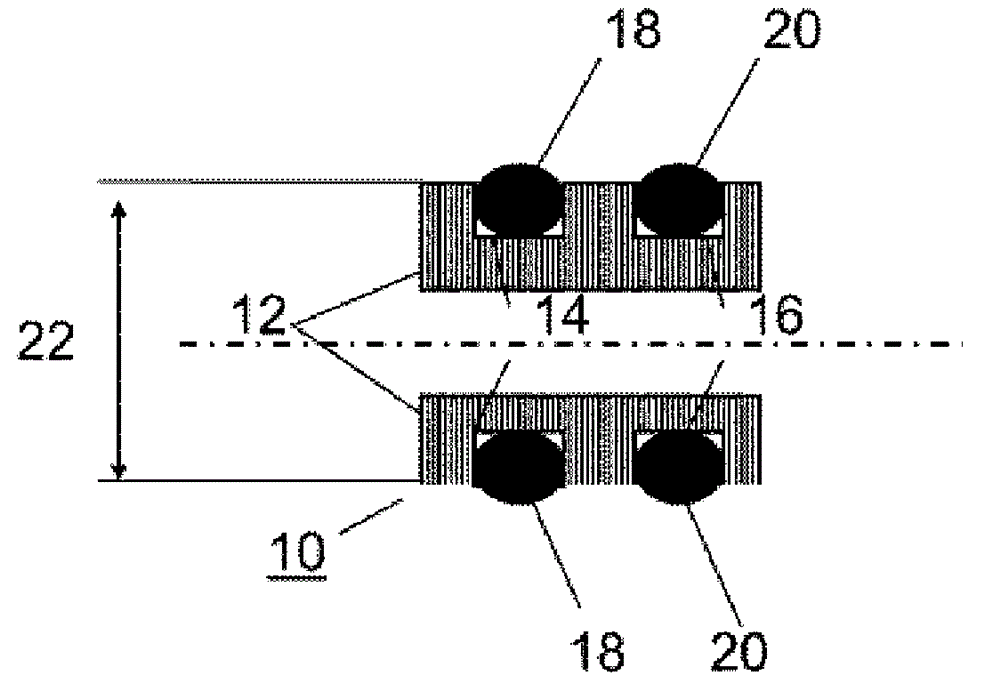

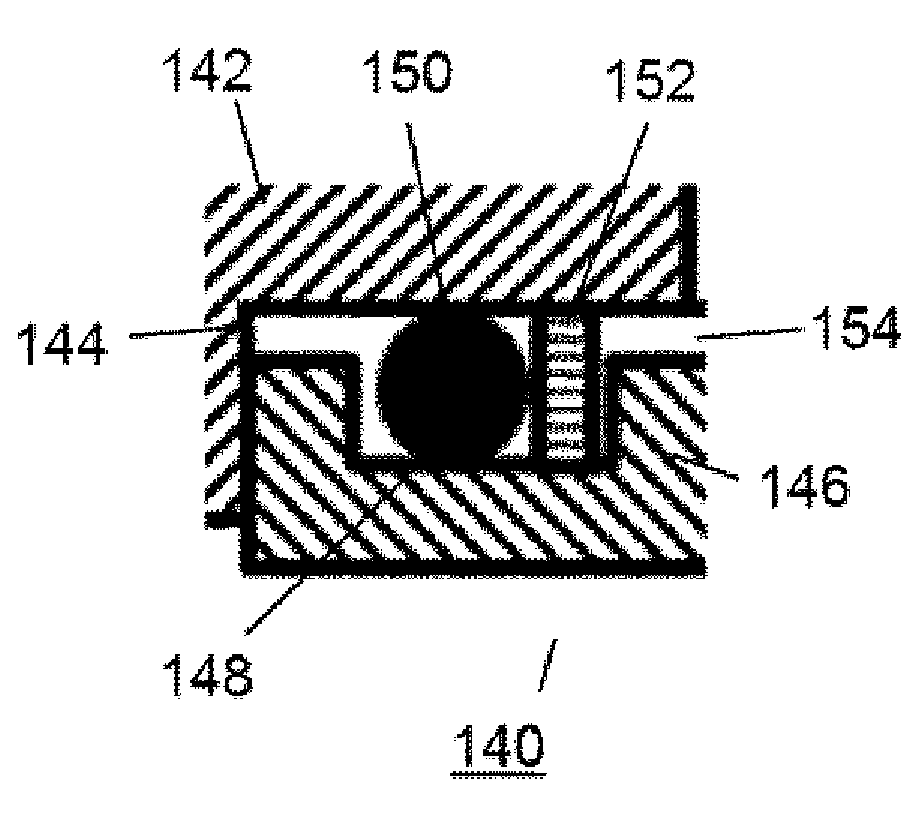

[0036] figure 1 A hydraulic connection sleeve 10 is shown which comprises a base body 12 which has at least two annular grooves 14 , 16 running around its outer cylindrical surface with sealing rings 18 , 20 inserted therein.

[0037] One possibility consists in designing the groove geometry according to the prior art. In the figures shown, the annular cross-sections of the sealing rings 18 , 20 protrude by way of example by 10-20% beyond the annular grooves 14 , 16 in order to ensure a minimum pre-compression in the installed state. However, it is also conceivable that the annular cross-sections of the sealing rings 18 , 20 protrude farther, for example to achieve a very high pre-compression. In order to create a uniform contact pressure of the sealing rings 18 , 20 it can be advantageous if all the sealing rings 18 , 20 protrude uniformly beyond the annular grooves 14 , 15 and are thus uniformly pre-compressed.

[0038] In the figures, the edges of the base body 12 are not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com