Relay valve for a pneumatic valve unit

A technology of relay valve and valve unit, which is applied in the field of relay valve for pneumatic valve unit, can solve the problems of high manufacturing cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

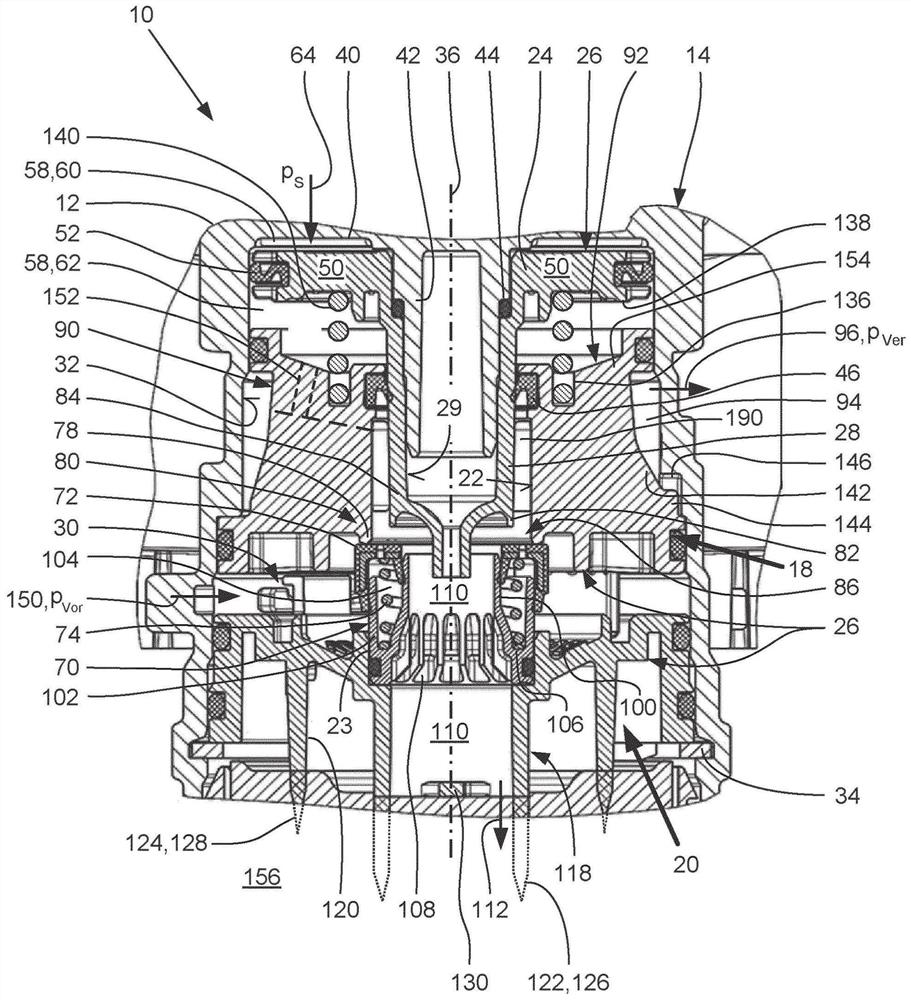

[0030] figure 1 The relay valve 10 shown in is accommodated in a housing 12 of a pneumatic valve unit 14 of a not shown brake system of a not shown commercial vehicle.

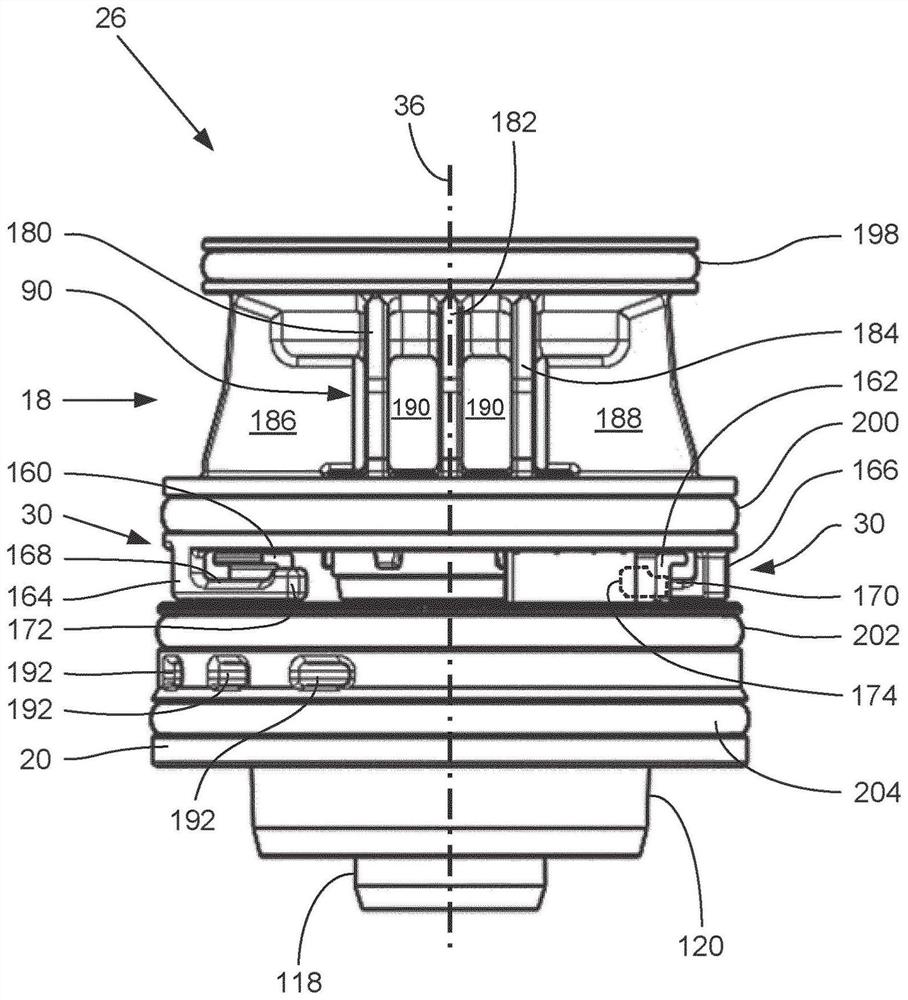

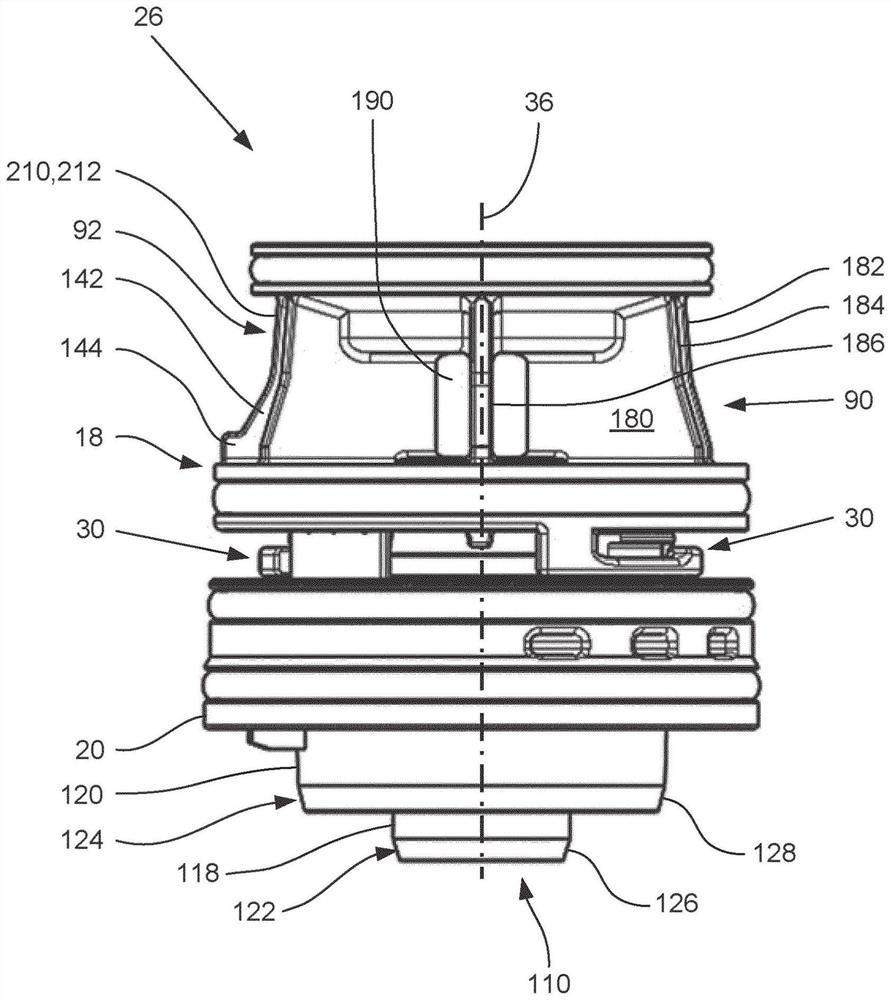

[0031] The relay valve 10 has a first assembly part 18 and a second assembly part 20 as well as a piston 24 , wherein the first assembly part 18 and the second assembly part 20 and preferably the piston 24 as a whole in the assembled state A pre-assembled unit 26 is formed. The first assembly part 18 and the second assembly part 20 are firmly connected to one another by means of a bayonet connection 30 and the hollow cylindrical guide area 28 of the piston 24 is centrally accommodated in the first assembly part in an axially displaceable manner. Within 18.

[0032] The pre-assembly unit 26 is inserted into the one-sided, pot-shaped and stepped inner wall 32 of the housing 12 of the valve unit 14 and is axially fixed and fastened therein by means of a retaining ring 34 only by way of example. . This results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com