Wiper lever comprising a wiper arm and a wiper blade which is connected to the same in an articulated manner

A wiper rod and wiper arm technology, applied in the field of wiper rods with a wiper arm and a wiper blade hinged on the wiper arm, can solve problems such as damage and tongue deviation, and achieve good wiping The effect of water sheet guiding and improving the safety and reliability of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

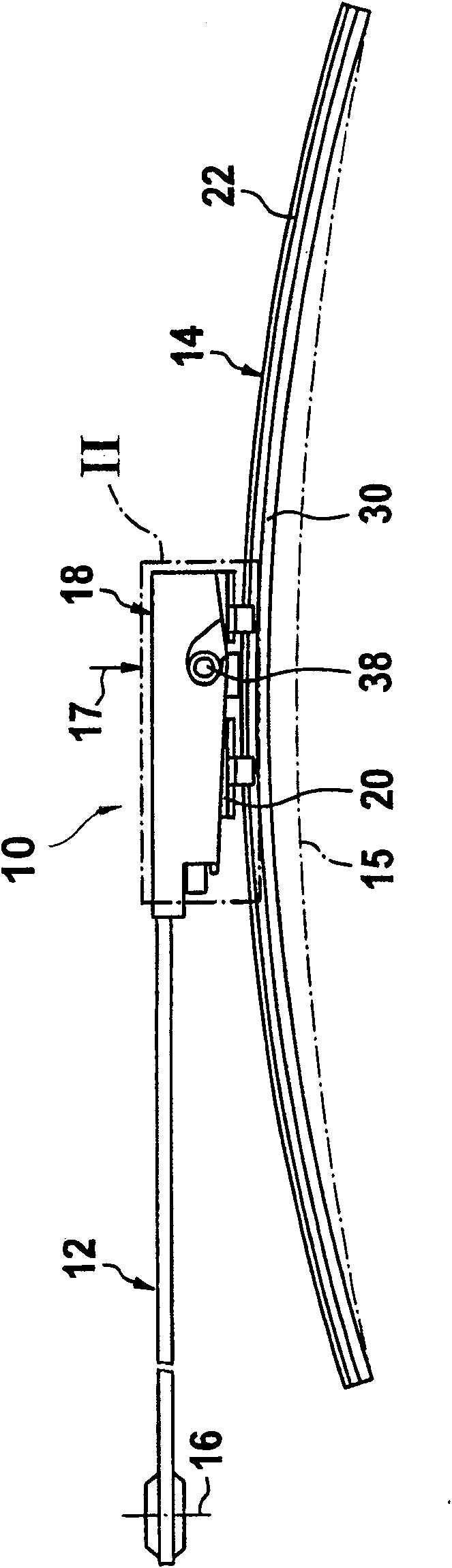

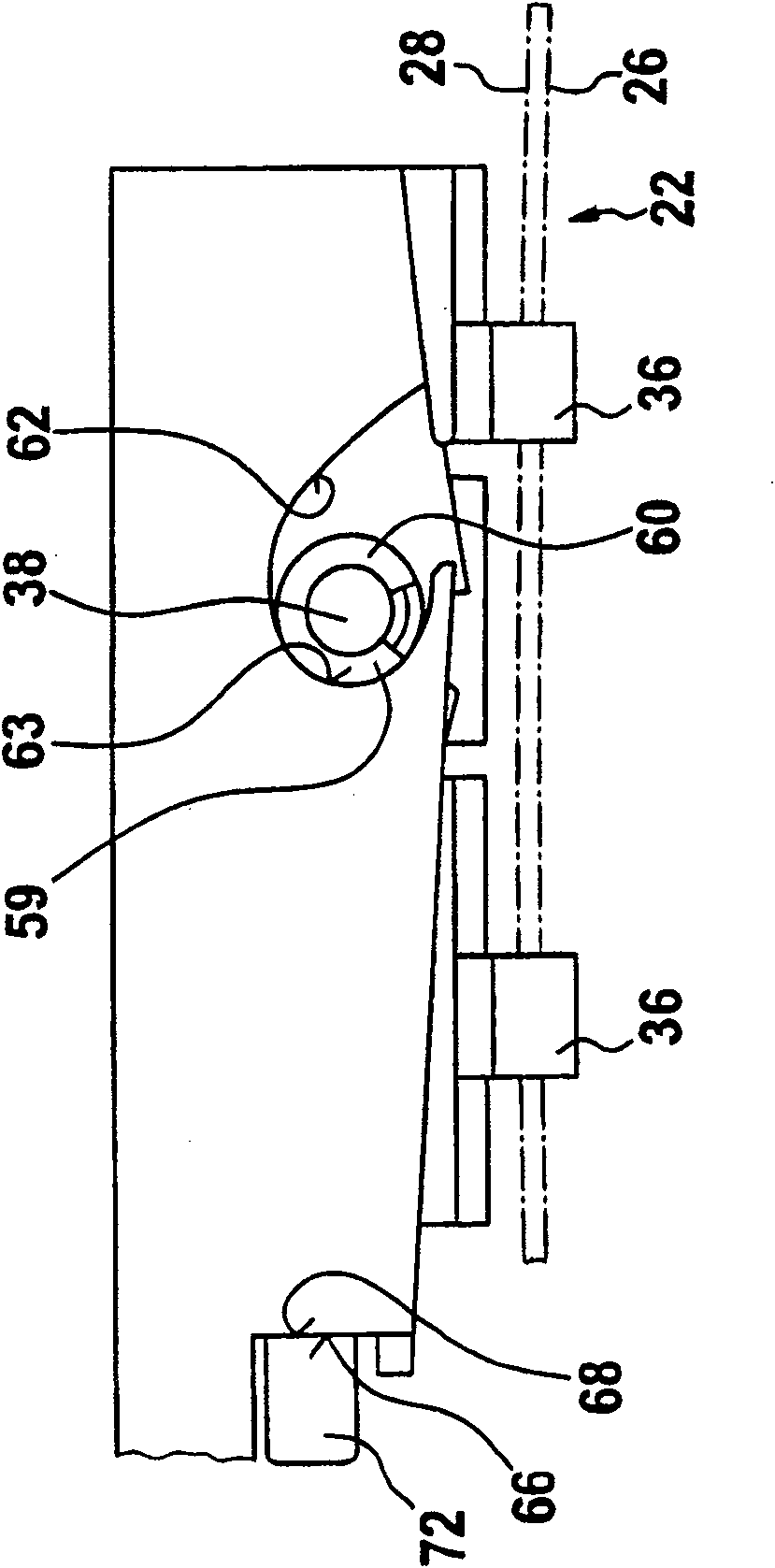

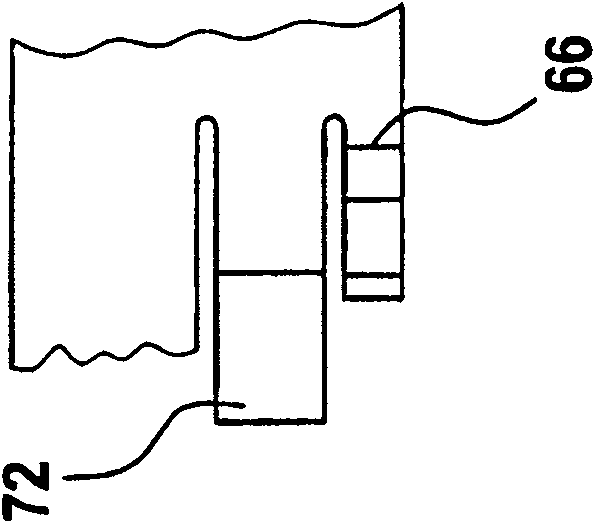

[0042] belong figure 1 The wiper lever 10 shown has a wiper arm 12 and a wiper blade 14 articulated thereon. The wiper arm 12 is driven pivotally at one end about an axis 16 . In order to be able to easily realize the articulated connection between the wiper arm and the wiper blade, the wiper arm is provided with a connecting block 18 ( figure 1 and 4 ), on which the wiper blade 14 with a hinge 20 can be connected via an adapter. The articulation 20 is fixedly connected to a carrier element 22 of the wiper blade 14, which in this exemplary embodiment has two spring bars 24 which lie in a common plane and are spaced apart from each other and are indicated by dotted lines. ( figure 2 ). The thus formed strip-shaped longitudinally extending spring-elastic support element 22 is bent in its longitudinal direction on its strip surfaces 26 and 28 ( figure 1 ). On its concavely curved strip surface 26, a rubber-elastic wiper strip 30 that can be attached to the glass window 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com