Solder strip shaping mechanism

A technology of welding ribbon and clamping mechanism, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of low photoelectric conversion efficiency of cells, high cost of use and maintenance, and complex structure of stringer welding machines, etc. problem, to achieve the effect of simple structure, convenient operation, and increase the secondary utilization of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

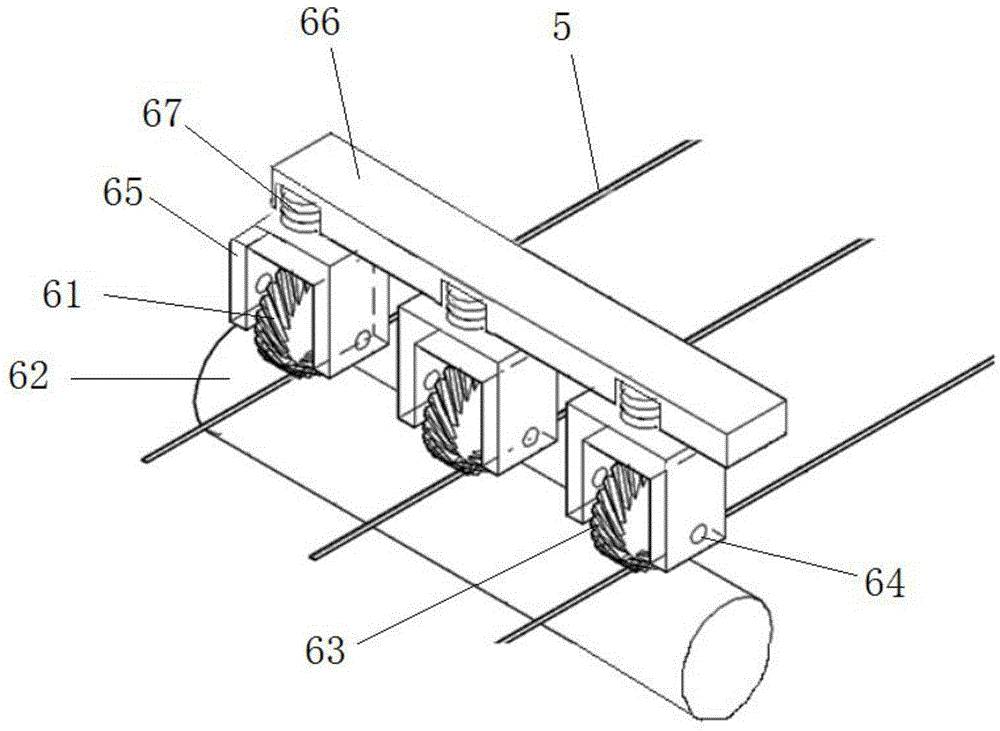

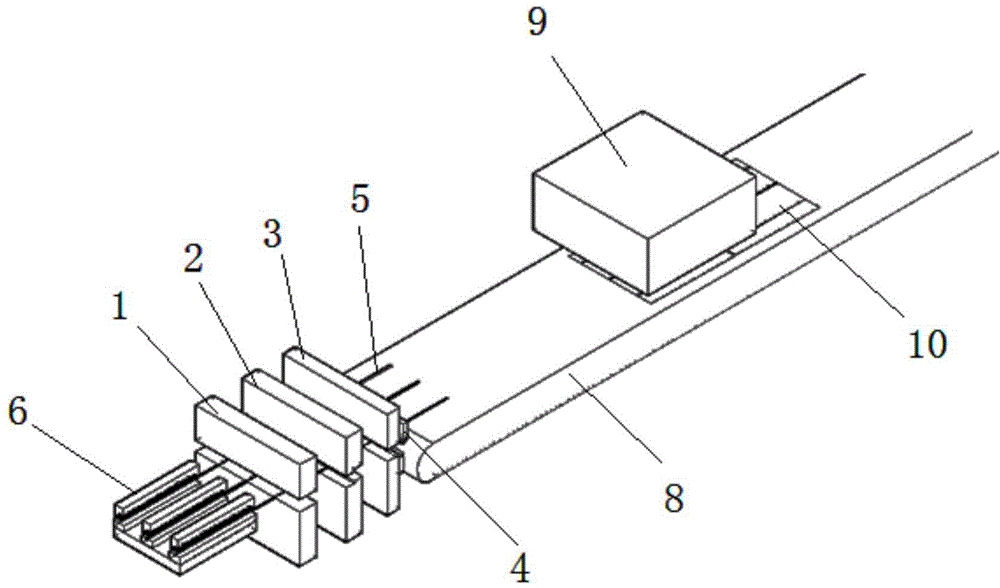

[0029] see Figure 1-2 , a welding ribbon shaping mechanism, which includes a welding ribbon stretching and clamping mechanism 1 arranged in sequence along the conveying direction of the welding ribbon 5, for guiding the welding ribbon 5 from the welding ribbon roll (not shown in the figure) to movement of one side of the weld, i.e. figure 1 Move from left to right in the middle; the ribbon bending mechanism 2 is used to bend the ribbon 5 into a "Z" shape (the "Z" shape mentioned here refers to bending the ribbon into a section to carry the battery The front side of the battery sheet, and the other half is equipped with the reverse side of the adjacent battery sheet) so that two adjacent battery sheets can be connected in series; the cutting and clamping mechanism 3 is used for clamping and fixing the welding ribbon 5 before cutting; the cutter 4 is used for Cutting off the welding ribbon 5 to process a battery string of a predetermined length; between the welding ribbon roll...

Embodiment 2

[0035] see Figure 3-4 , on the basis of the above-mentioned embodiment 1, the indentation mechanism 6 in this embodiment is replaced by the following structure:

[0036] The indentation mechanism 6 includes a stamping block 71 and a backing plate 72, the welding ribbon 5 passes between the stamping block 71 and the backing plate 72, and stamping protrusions are arranged on the stamping surface of the stamping block 71 The stamping block 71 can approach or move away from the backing plate 72 driven by the driving mechanism, and the upper surface of the backing plate 72 is a flat surface. When the driving mechanism drives the punching plate 71 to move toward the side close to the backing plate 72, the upper surface of the welding ribbon 5 is embossed with preset indentations; , There will be no dents at the embossed place on the welding strip 5 . This structural design is convenient for pressing required dents at predetermined positions of the welding strip, that is, pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com