Power input assembly for film plating of solar battery

A technology for solar cells and charging components, applied in the field of solar cells, can solve the problems of short service life and easy breakage, and achieve the effects of simple use, extended service life and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

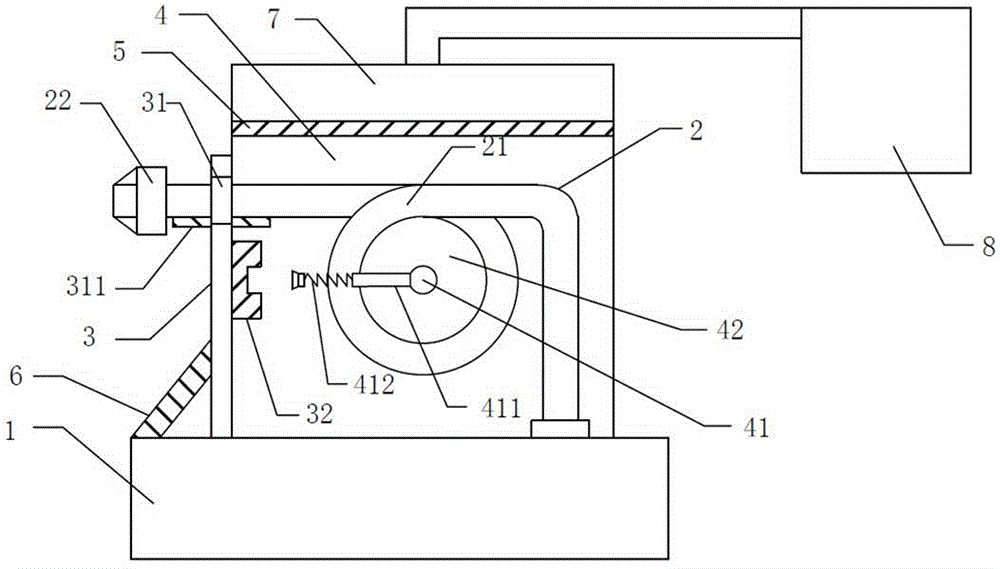

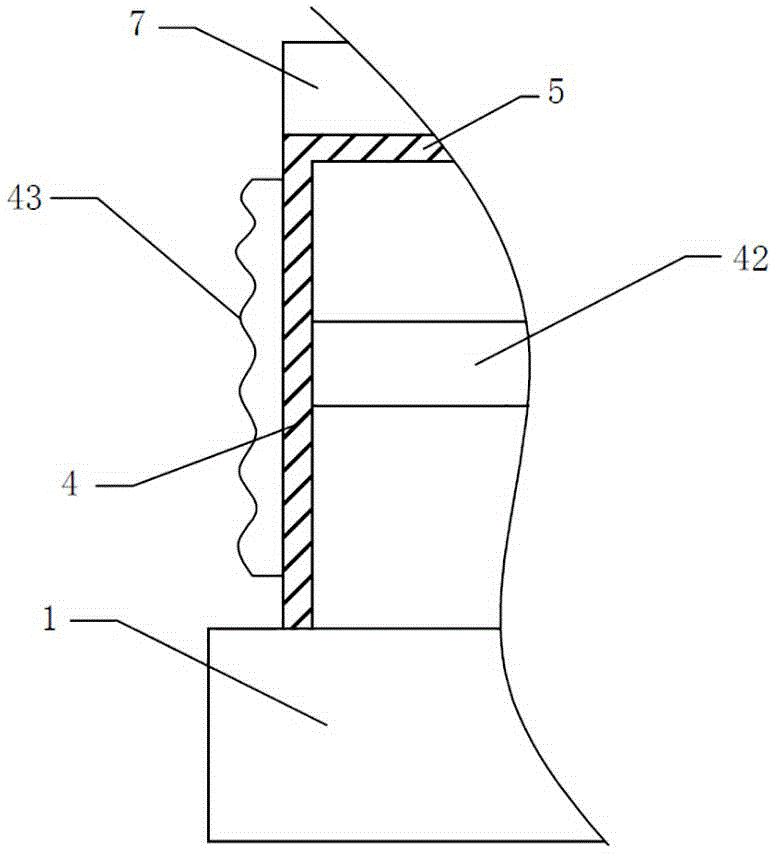

[0019] See figure 1 , figure 2 , a power-feed assembly for solar cell coating, including a tooling frame 1, and a power-feeding unit fixedly connected to the tooling frame 1, the power-feeding unit includes a power-feeding cable 2 fixedly connected to the tooling frame 1 1. The support baffle 3 fixedly connected to the tooling frame 1 and the protective cover fixedly connected to the support baffle 3 for isolating the incoming cable 2, inside the protective cover is provided with a support for the incoming cable 2 to rotate and fix Wiring device. The length of the power-in cable 2 is larger than normal, about 50-60cm.

[0020] The protective cover includes a side plate 4 which is fixedly connected to the support baffle plate 3 and has a chute and a top plate 5 which is fixedly connected between the side plates 4; The bobbin body 42 on 41 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com