A catenary balance line fault detection method based on dhog and discrete cosine transform

A discrete cosine transform and fault detection technology, applied in character and pattern recognition, instruments, computer components, etc., can solve problems such as increased vibration frequency of the pantograph-catenary system, and achieve good resistance to scale invariance, good accuracy, and Overcoming the low efficiency of manual inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The embodiment of the present invention will be described in further detail below in conjunction with the actual pictures taken in the experiment.

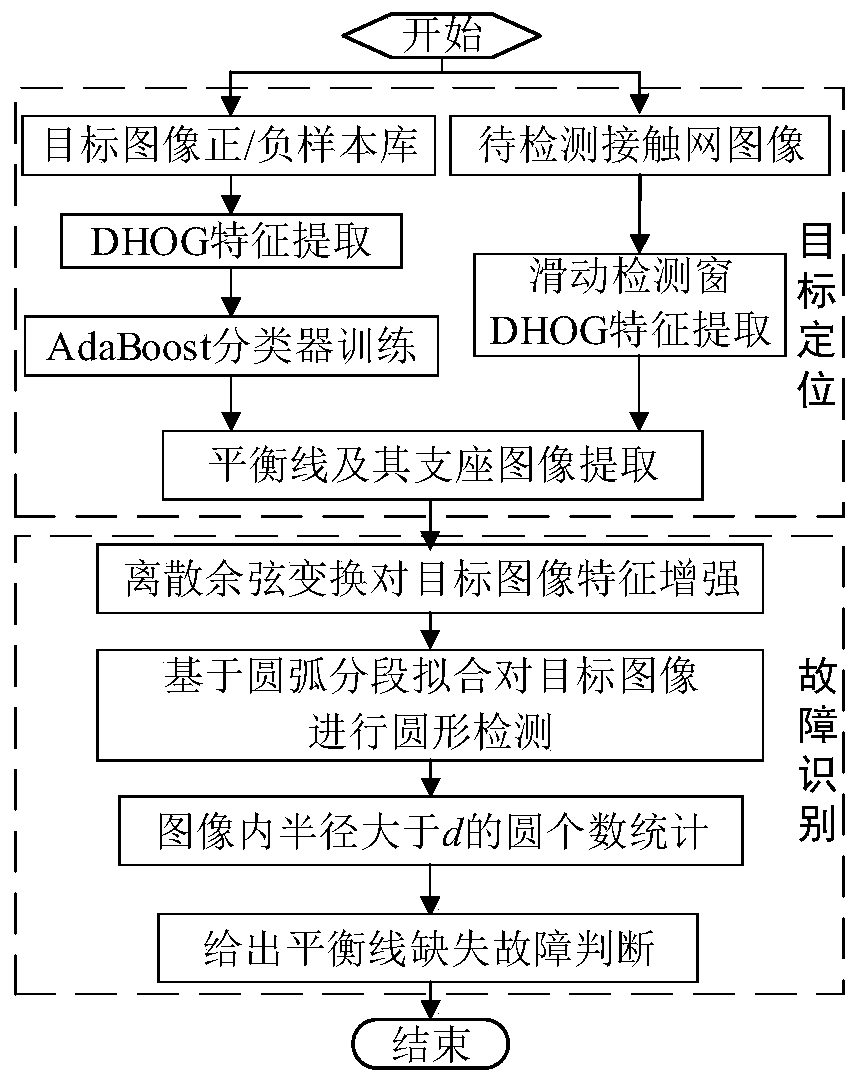

[0062] combine figure 1 Shown: the detection flowchart of the method proposed in this paper of the present invention.

[0063] The main steps are as follows: firstly, the DHOG feature needs to be extracted from the image of the sample library, on this basis, the AdaBoost classifier is trained and the precise positioning of the balance line and its support is given; secondly, the discrete cosine transform is used to analyze the target feature information of the balance line and its support Enhancement; then based on the arc segment fitting, the circle in the image is detected and counted, and the fault criterion is given according to the statistical number, and finally the fault judgment of the missing balance line of the high-speed rail catenary is realized.

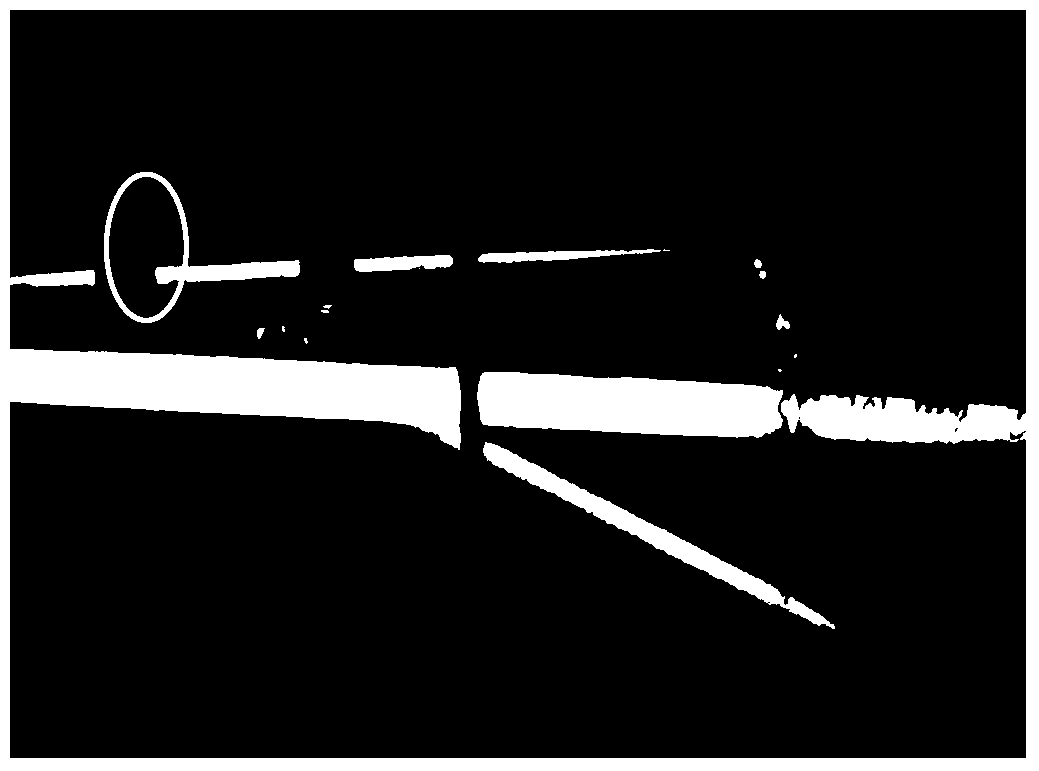

[0064] figure 2 It is a partial image of the high-speed railw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com