Glass substrate having black matrix, preparation method thereof, and liquid crystal panel

A technology of black matrix and glass substrate, which is applied in the field of glass substrate with black matrix and its preparation, can solve the problems of lower aperture ratio of liquid crystal panel, which is not conducive to reducing product cost and product quality, and achieve the effect of reducing dark lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

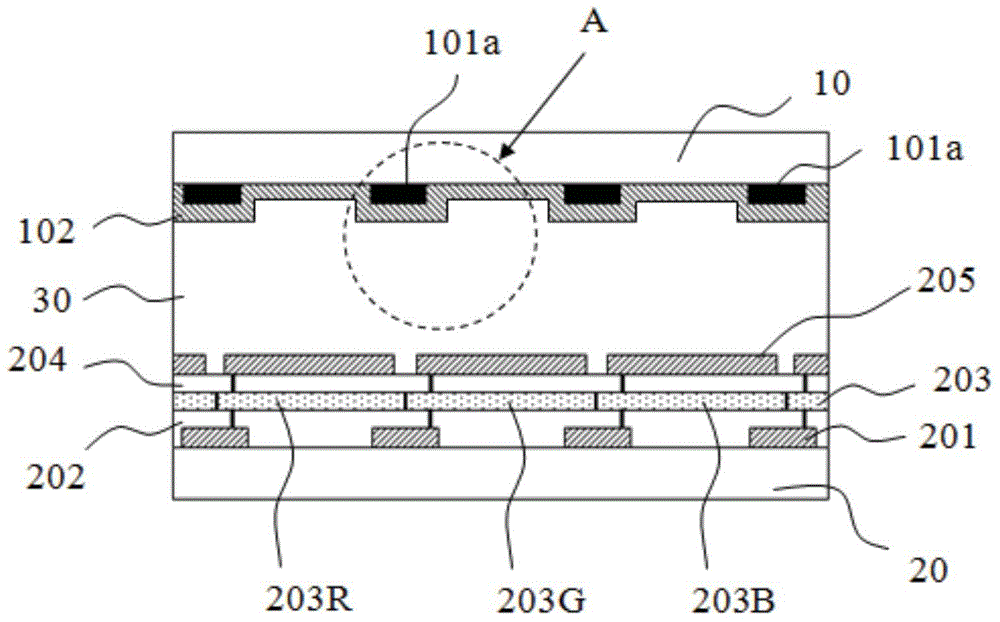

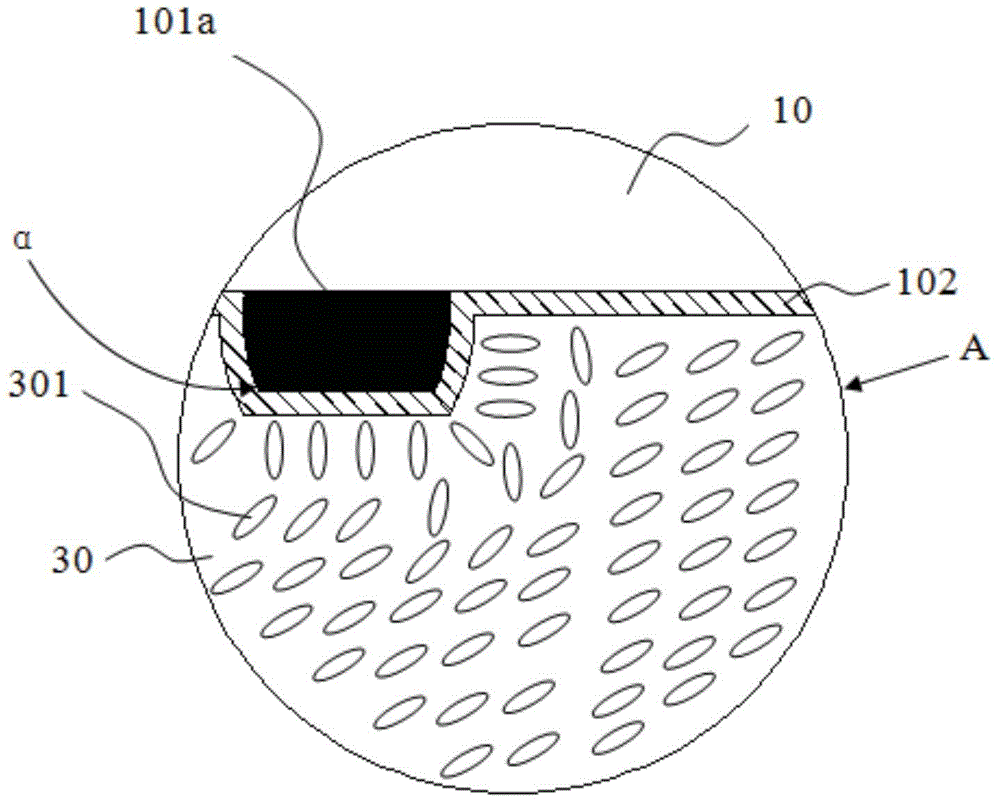

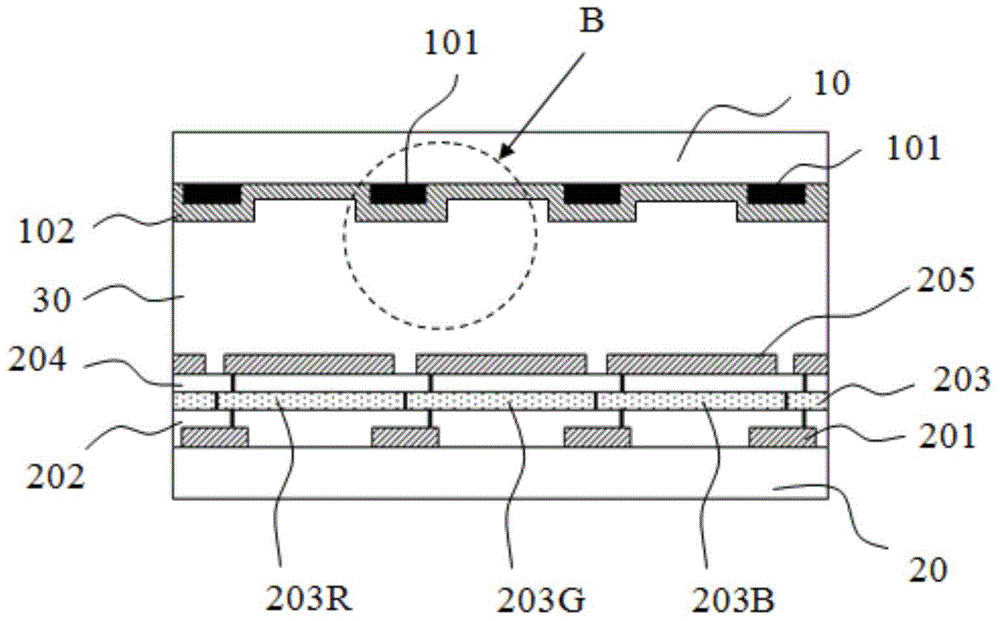

[0029] As mentioned above, the present invention provides a glass substrate with a black matrix for the defects of dark lines on the edge of the pixel due to the sharp corners of the edge of the black matrix in the COA liquid crystal panel of the prior art, which has a black matrix The glass substrate includes a glass substrate and a black matrix array formed on the glass substrate, wherein the thickness of the black matrix gradually decreases from the middle to both ends. By improving the shape of the black matrix, the edge of the black matrix is no longer in the shape of a taper angle, and the arrangement of the liquid crystal molecules in the liquid crystal layer close to the black matrix area is not much different from that of the liquid crystal molecules outside the area. Fixed an issue where pixel edges had dark lines due to black matrix edges having sharp corners.

[0030] The technical solutions in the embodiments of the present invention will be described in detail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com