Common pump station for forklift torque converter and clutch testing

A torque converter and clutch technology is applied in the field of performance testing of transmission parts, which can solve the problems of troublesome operation and high investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

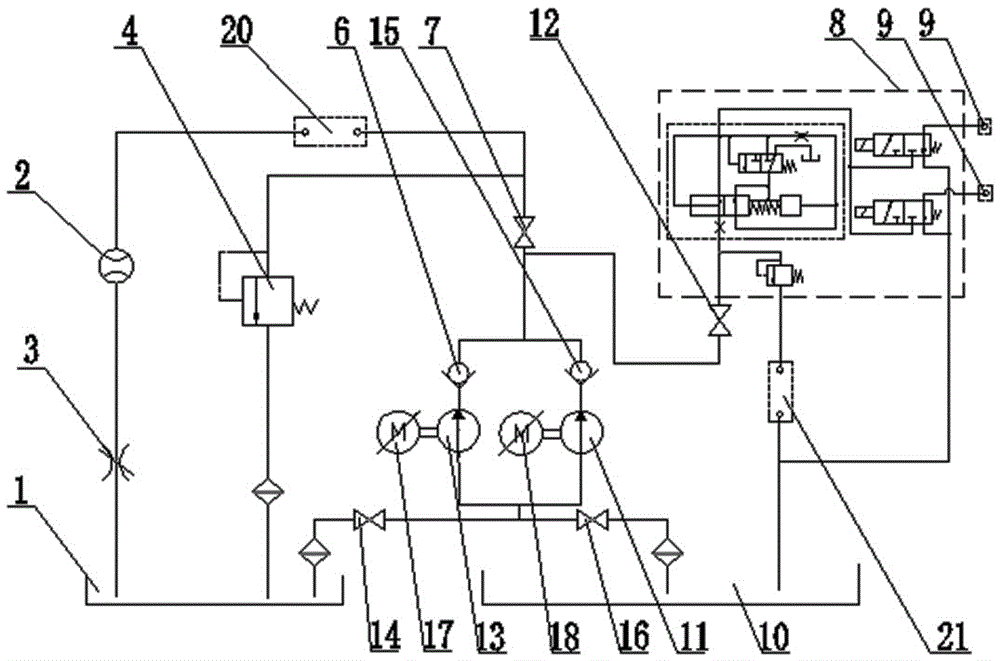

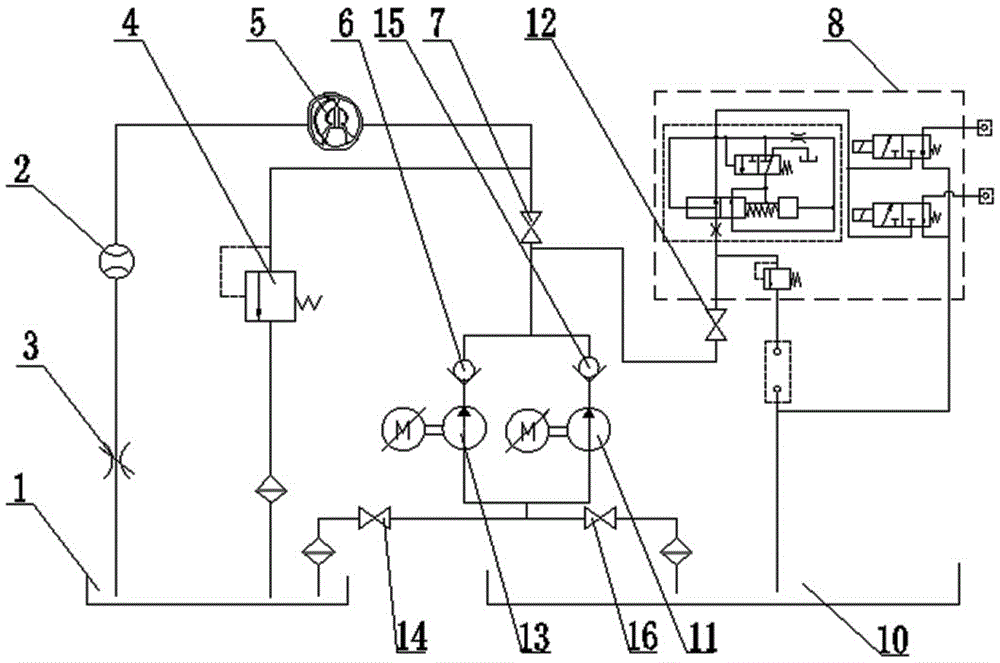

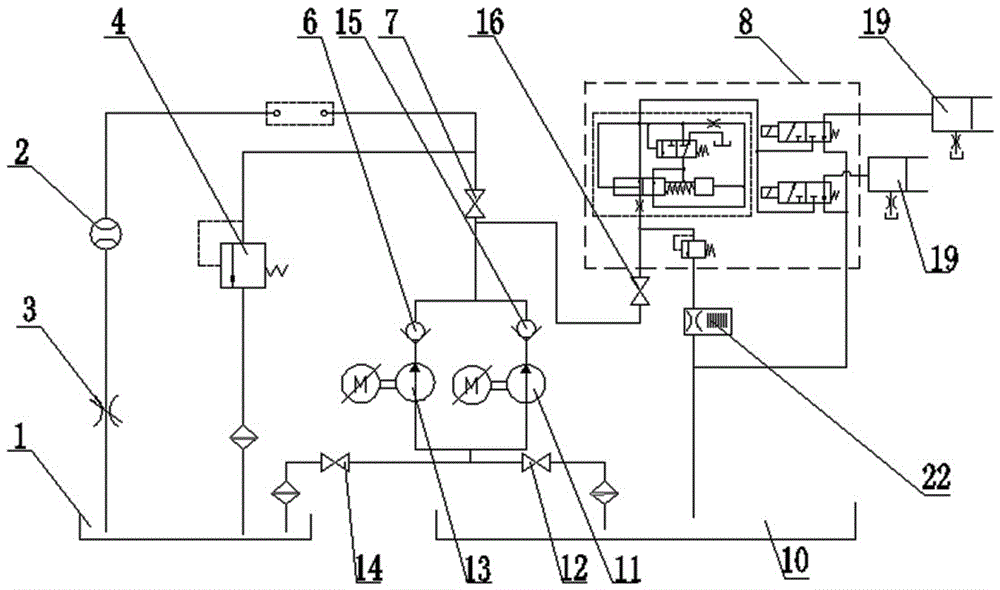

[0032] see figure 1 , the common pumping station used for forklift torque converter and clutch test includes two oil tanks, two electric motors, two oil pumps, two one-way valves, four stop valves, overflow valve 4 and control valve assembly 8;

[0033] The two fuel tanks are respectively the first fuel tank 1 and the second fuel tank 10;

[0034] The two motors are respectively a first motor 18 and a second motor 17, the first motor 18 and the second motor 17 are variable frequency motors, the power of the first motor 18 is 2.2Kw, and the power of the second motor 17 is 1.5Kw.

[0035] The two oil pumps are respectively the first oil pump 11 and the second oil pump 13, both of which are gear pumps, with displacements of 45mL / r and 20mL / r respectively.

[0036] The two one-way valves are respectively the first one-way valve 6 and the second one-way valve 15;

[0037] The four shut-off valves are respectively the first shut-off valve 7, the second shut-off valve 12, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com