Performance test bench position arranging method for tilted-angle transmission-gear box

A layout method and gearbox technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as impact and torsional vibration, gearbox vibration and noise, and affect the normal meshing of gear pairs, so as to eliminate shock and vibration and run smoothly , the effect of convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

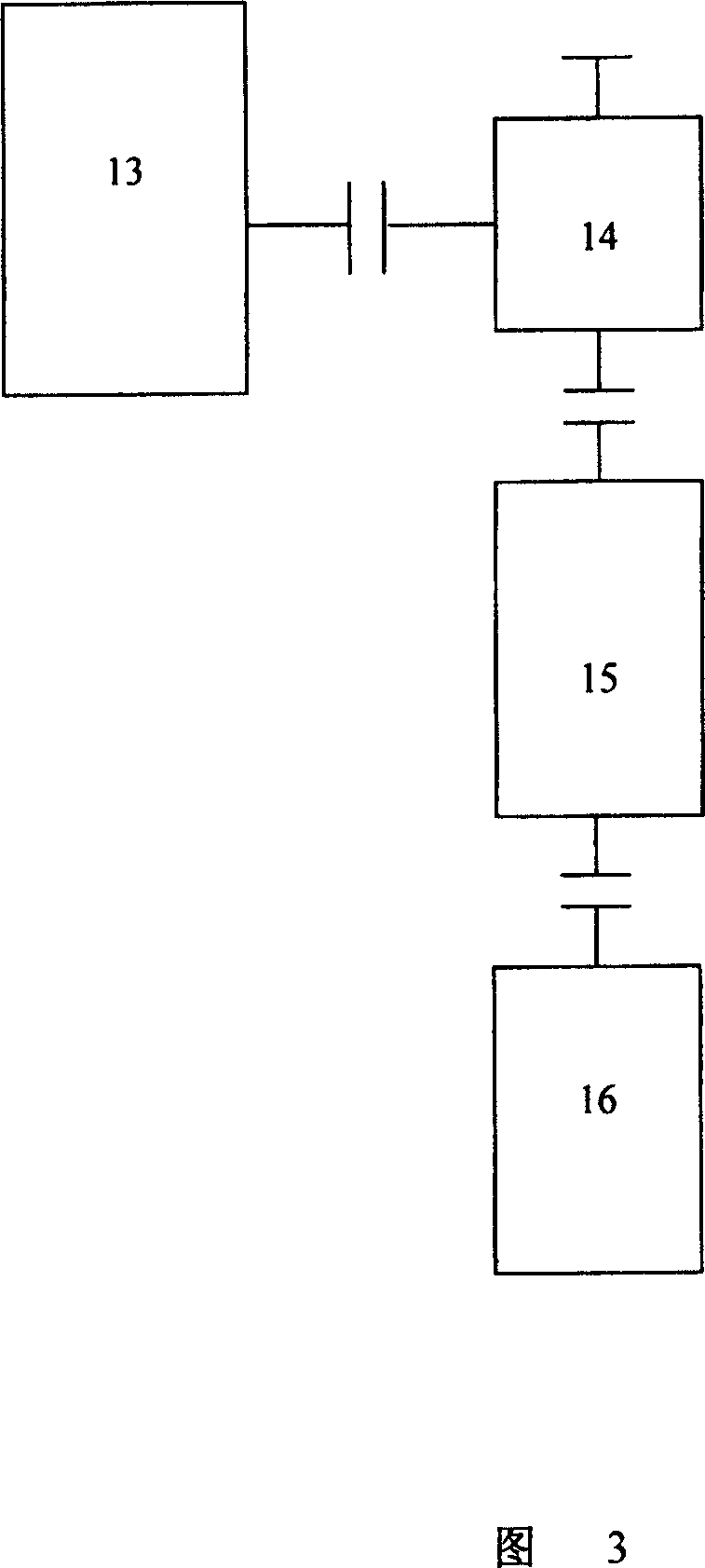

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings: as shown in Figure 2 and Figure 3, the layout on the test bench is: the drive motor 11 is connected with the input shaft of the tested gear box 13 through the input sensor 12, and the tested gear The output end of the box 13 is connected with the input end of the steering gear box 14 which can be tilted, and the output end of the steering gear box 14 is connected with the loader 16 through the output sensor 15 . This arrangement eliminates the shock and vibration caused by angular velocity adjustment due to the cancellation of the universal joint in the traditional arrangement, thus achieving smooth operation. The steering gear box of the present invention has two input ends, which make the layout of the test bench arbitrarily selected according to the actual conditions of the test site, thereby greatly facilitating the layout and installation of the entire test bench. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com