Upside-down construction method for large-span ultra-high signal-layer cylindrical architectural steel structure

A construction method and large-span technology, which is applied in building construction, construction, and building materials processing, etc., can solve the problem that the hoisting height cannot meet the hoisting requirements, achieve the ability to meet the hoisting requirements, reduce the risk of high-altitude operations, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

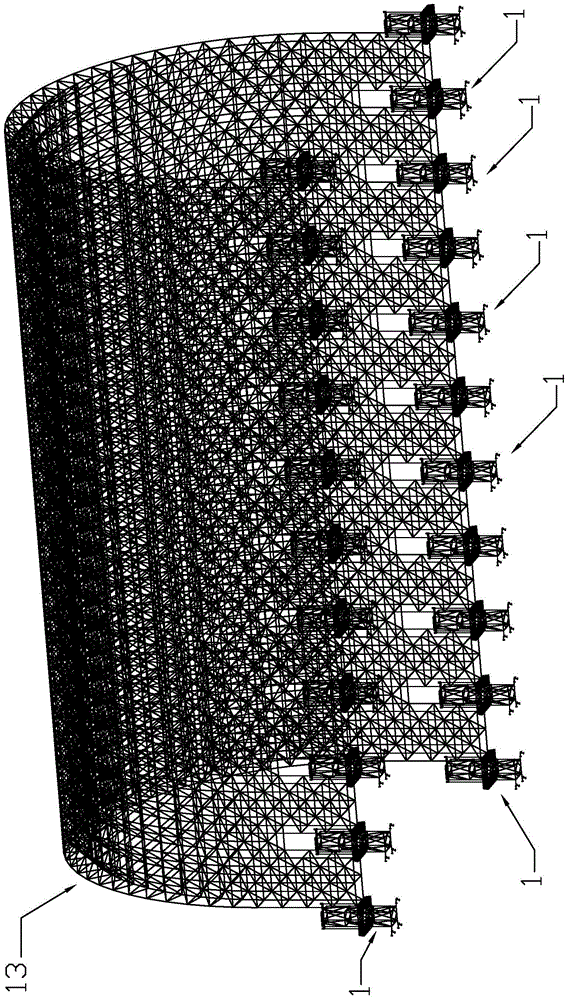

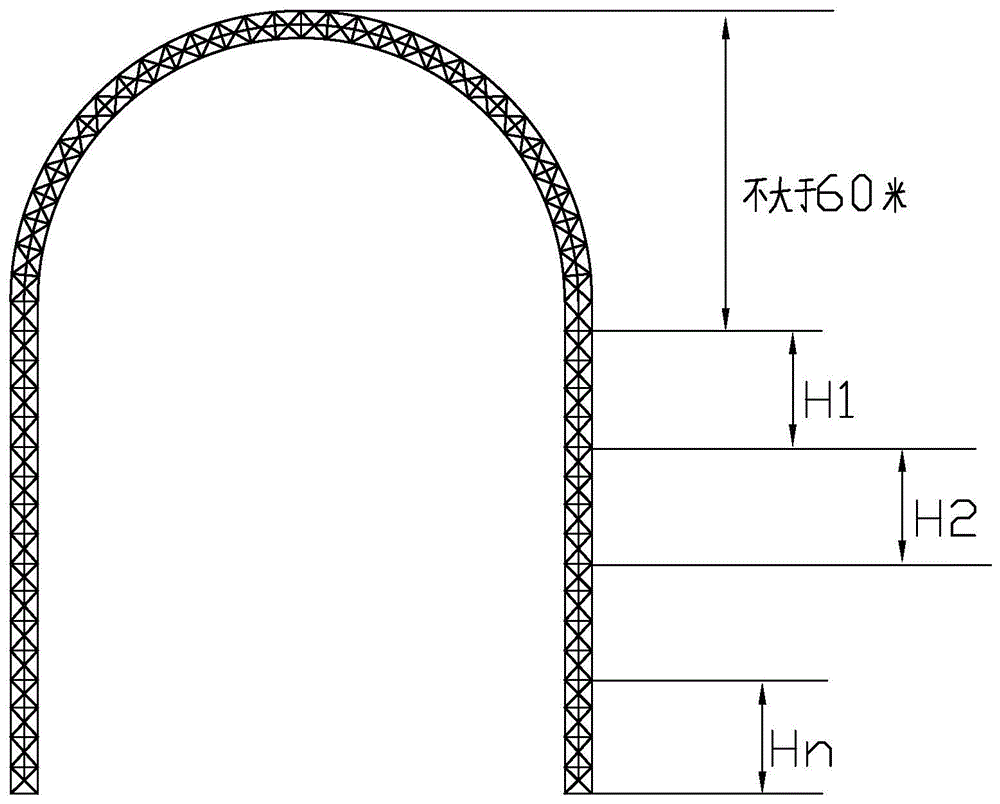

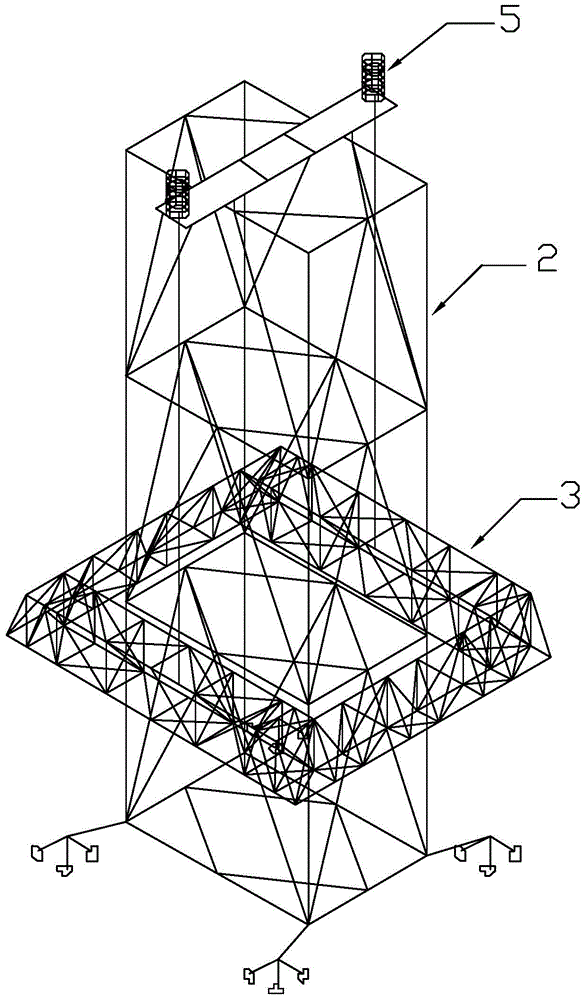

[0036] Such as Figure 1 to Figure 7 Shown is a large-span ultra-high single-story cylindrical building steel structure flip-chip construction method of the present invention, including the following steps:

[0037] ① Clean up the foundation plane first, measure and check the released axis, pop out the axis with ink line, and set a mark on the axis of the foundation surface, and then assemble the steel structure of 60 meters on the top and its attached light steel at the level of 0 meters in situ Structural enclosure, with the 60-meter steel structure at the top and its attached light steel structure enclosure as the first process, when assembling the steel structure and light steel structure enclosure, the center position of the overall structure is positioned and adjusted Height difference, and non-destructive testing of the weld joint;

[0038] ② The lifting tooling system 1 is installed in place, and the number and location of the lifting tooling system 1 are determined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com