Anti-swelling and sand-inhibiting agent for high-permeability heavy oil reservoir and preparation method of anti-swelling and sand-inhibiting agent

A technology of heavy oil reservoirs and sand inhibitors, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of permeability drop, dispersion and migration, and reduce reservoir permeability, so as to inhibit the reservoir Layer clay swelling, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

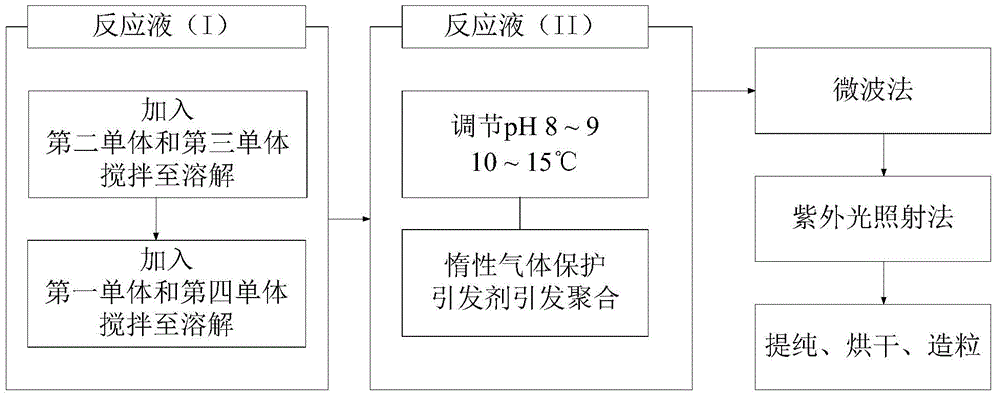

Method used

Image

Examples

Embodiment 1

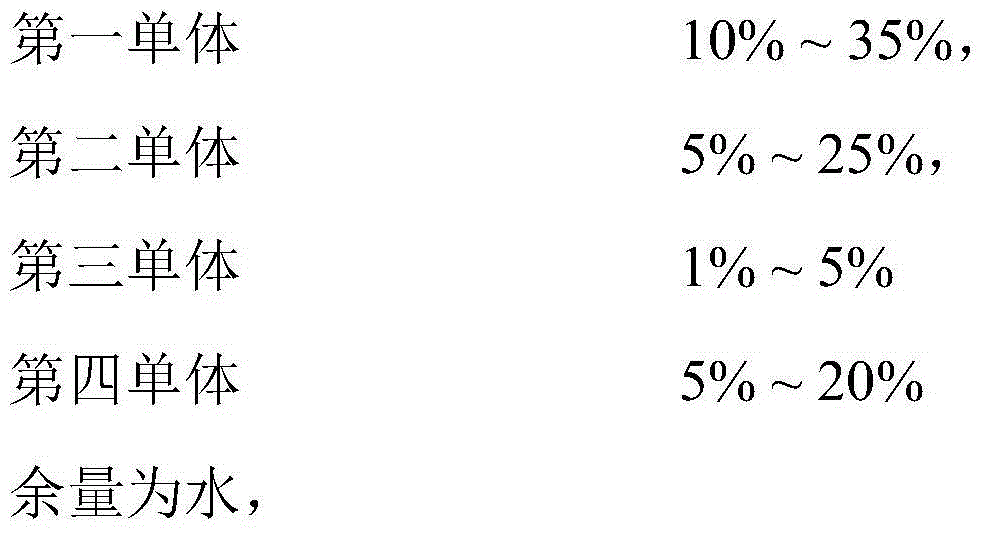

[0033] The weight percent of each monomer and water is: methacrylamide: 2-acrylamide-2-methylpropanesulfonate: styrene: acryloyloxyethyltrimethylammonium chloride: water = 25:10: 5:7:53.

[0034] Add 530g of distilled water into a 2000mL beaker, add 100g of 2-acrylamide-2-methylpropane sulfonate and 50g of styrene, stir until all the solids are dissolved, then add 250g of methacrylamide and acryloyloxyethyl trimethyl Ammonium chloride 70g, continue to stir until completely dissolving, obtain mixed reaction solution (I); Regulate the pH value of mixed reaction solution (I) with sodium hydroxide solution and adjust to pH=8, and control solution temperature to be 10~15 ℃; Top blow nitrogen for 30 minutes to remove oxygen, add potassium persulfate 0.07g / L, sodium bisulfite 0.07g / L, and induce the generation of free radicals for 20 minutes. If the temperature rises, it is considered as a successful initiation, otherwise it is necessary to add initiator Re-initiate the agent; raise...

Embodiment 2

[0036] The weight percent of each monomer and water is: methacrylamide: 2-acrylamide-2-methylpropanesulfonate: acrylonitrile: acryloyloxyethyltrimethylammonium chloride: water=30:12: 2:10:46.

[0037]Add 460g of distilled water to a 2000mL beaker, add 120g of 2-acrylamide-2-methylpropane sulfonate and 20g of acrylonitrile, stir until all the solids are dissolved, then add 300g of methacrylamide and acryloyloxyethyl trimethyl Ammonium chloride 100g, continue to stir until completely dissolving, obtain mixed reaction solution (I); Regulate the pH value of mixed reaction solution (I) with sodium hydroxide solution and adjust to pH=8.5, and control solution temperature is 10~15 ℃; Top blow nitrogen for 30 minutes to remove oxygen, add potassium persulfate 0.04g / L, sodium bisulfite 0.04g / L, and induce free radicals for 20 minutes. If you see a rise in temperature, it is considered a successful initiation, otherwise you need to add initiator Re-initiate the agent; raise the tempera...

Embodiment 3

[0039] The weight percent of each monomer and water is: acrylamide: 2-acrylamide-2-methylpropanesulfonate: styrene: trimethylallyl ammonium chloride: water = 20:15:3:12: 50.

[0040] Add 500g of distilled water to a 2000mL beaker, add 150g of 2-acrylamide-2-methylpropanesulfonate and 30g of styrene, stir until all the solids are dissolved, then add 200g of acrylamide and 120g of trimethylallyl ammonium chloride , continue to stir until fully dissolved to obtain the mixed reaction solution (I); adjust the pH value of the mixed reaction solution (I) to pH=9 with sodium hydroxide solution, and control the solution temperature to be 15°C; Oxygen, add potassium persulfate 0.06g / L, sodium bisulfite 0.06g / L, induce 20 minutes to generate free radicals, if you see the temperature rise, then it is considered as a successful initiation, otherwise you need to add an initiator to re-initiate; set the temperature Raise to room temperature, heat for 3 minutes with microwave method at mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com