Compost for industrialized production of coprinus comatus

A compost and technology of Coprinus comatus, applied in the direction of application, fertilizer mixture, fertilization device, etc., can solve the problems that biogas residue cannot be processed, and achieve the effects of shortening the production cycle, reducing environmental pollution, and low heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

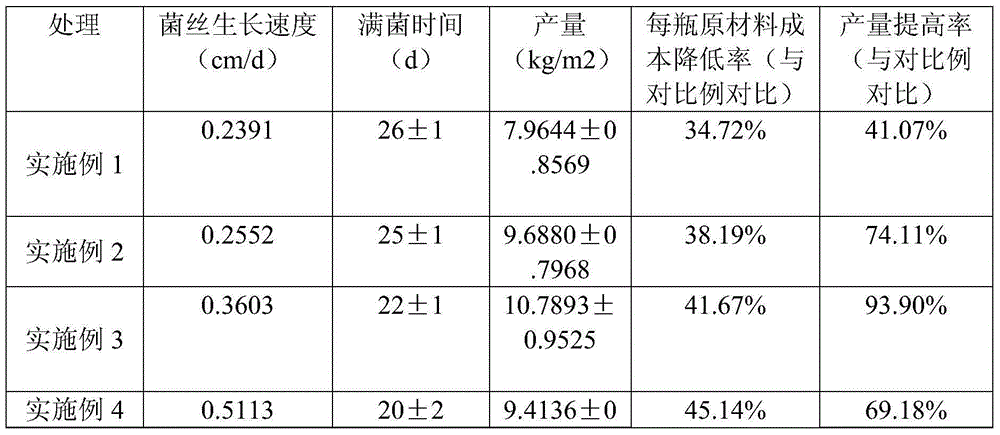

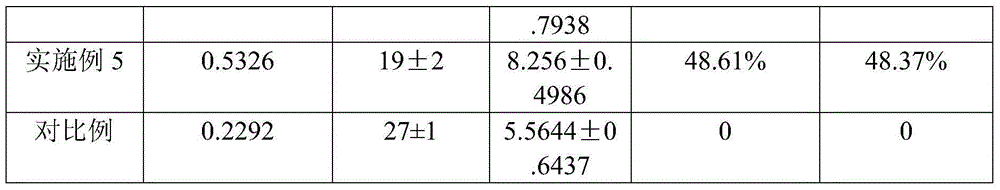

Embodiment 1

[0036] Take by weighing biogas residue 50kg, corn cob 30kg, bran 13kg, corn flour 5kg, gypsum 2kg respectively, and its dry material weight percent is biogas residue 50%, corncob 30%, bran 13%, corn flour 5%, gypsum is 2%. Stir the dry material evenly, then add water and stir until it is completely mixed, so that the water content reaches 55%-60%, bottle it with a machine, about 700g of wet material per bottle, autoclave at 121°C for 2 hours, and artificially inoculate Coprinus comatus The strains (inoculum size 3% V / V) were cultured (cultivation conditions were temperature 23°C, humidity 65%-75%, CO 2 Concentration of 1500ppm), dig the bottle after full of bacteria, dig the bottle and compact it in a 100cm*50cm*30cm basket. Mushrooms (the conditions for fruiting are temperature 16°C-18°C, humidity 91%-95%) to count indicators such as the germination period, harvested fruiting time, mushroom weight, biotransformation rate, and fruiting output per square meter .

Embodiment 2

[0038] Weigh 55kg of biogas residue, 25kg of corn cob, 13kg of bran, 5kg of corn flour, and 2kg of gypsum, and stir evenly. The weight percentage of the dry material is 55% of biogas residue, 25% of corn cob, 13% of bran, 5% of corn flour and 2% of gypsum. All the other are with embodiment 1.

Embodiment 3

[0040] Weigh 60kg of biogas residue, 20kg of corn cob, 13kg of bran, 5kg of corn flour, and 2kg of gypsum, mix them evenly, add 150kg of water and stir evenly. The weight percentage of the dry material is 60% of biogas residue, 20% of corn cob, 13% of bran, 5% of rice flour and 2% of gypsum. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com