Device and method for coating OPP film with heat-seal glue in fixed point mode

A heat-sealing glue and glue coating technology, which is applied in the device, coating, general parts of printing machinery, etc. for coating liquid on the surface, which can solve the problem that the transparency of the packaging bag cannot meet the transparent requirements. High sealing strength, inconvenient for consumers to unpack, etc., to achieve the effect of suitable heat sealing strength, high flatness, and convenient unpacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

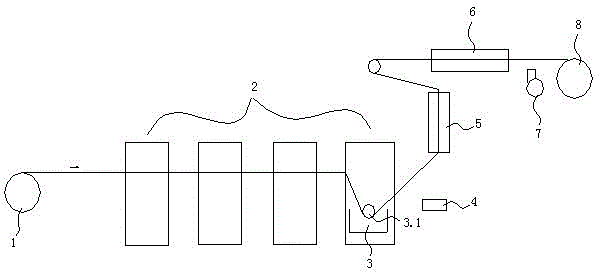

[0017] Such as figure 1 As shown, the device for applying heat-sealing adhesive to fixed-point coating of OPP film in this embodiment includes printed film unwinding 1, printing unit 2, heat-sealing adhesive coating 3, first drying aisle 5, and second drying aisle. Drying aisle 6, air cooling device 7 and printing film winding 8, wherein the heat-sealing glue coating 3 is arranged on the end printing machine of the printing unit 2, and the heat-sealing glue coating 3 is equipped with an electric engraving gravure roller 3.1, the electric The gravure roller 3.1 is matched with the heat-sealing arrangement of the printing film to realize fixed-point coating of the heat-sealing glue on the heat-sealing arrangement area of the printing film; the length of the first drying aisle 5 is 3-4m; the second The length of the second drying passage 6 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com