A metal-cored welding wire for welding automobile exhaust pipes

A technology of automobile exhaust and metal core, which is applied in the direction of welding medium, welding equipment, metal processing equipment, etc., can solve the problems affecting the service life of automobiles, exhaust pipe weld seam oxidation, weld seam fracture, etc., and achieve high production efficiency, Beautiful weld shape and stable molten pool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific examples.

[0014] The ferritic stainless steel metal-cored welding wire provided by the solution of the present invention is composed of a corresponding sheath and a flux core of the welding wire filled in the sheath.

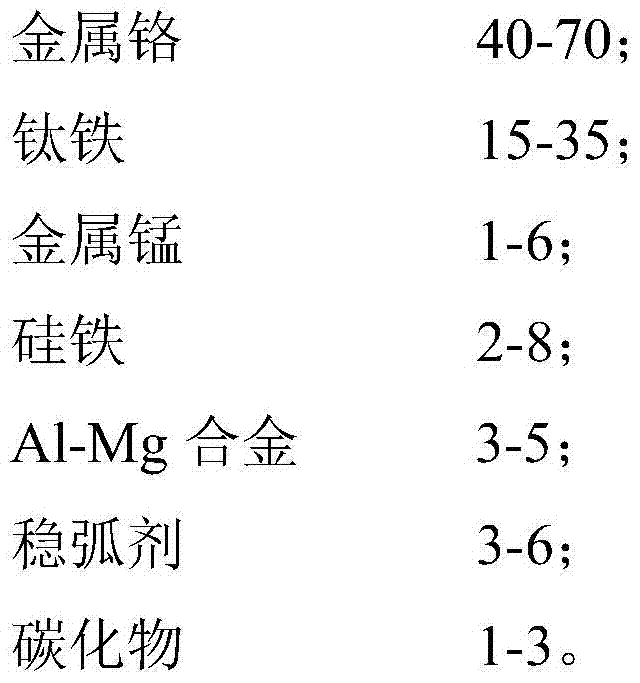

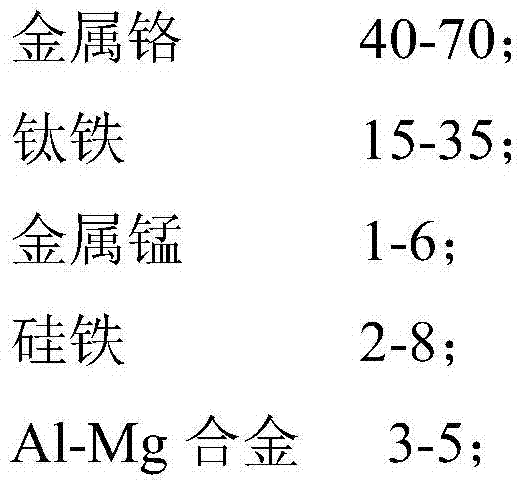

[0015] In order to achieve good high-temperature oxidation resistance and corrosion resistance, the flux core of the welding wire in the scheme of the present invention includes a large amount of deoxidizing and denitrifying agent, very little slagging agent and an appropriate amount of strengthening alloy elements. The main components and weight percentage of the metal core are as follows :

[0016]

[0017]

[0018] In order to further improve the resistance to high temperature oxidation and intergranular corrosion of the weld, 1-3% carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com