Fermented soybean meal, bacterial strain and application thereof

A technology for fermenting soybean meal and soybean meal, applied in application, fungi, climate change adaptation, etc., can solve the problems of high content of anti-nutritional factors, low protein utilization rate, low protein content, etc., and achieve low content of anti-nutritional factors, small peptides The effect of high content and high protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The expanded cultivation of embodiment 1 Aspergillus awamori

[0024] Inoculate Aspergillus awamori strain42 into PDA medium and culture at 25-30°C for 2-3 days to obtain slant bacteria; inoculate slant bacteria to seed medium and culture at 25-30°C for 2-3 days to expand The final Aspergillus awamori spores are washed with sterile water, the spores are collected, and the spores are prepared into a spore suspension with sterile water; the final concentration of the seed medium is composed of: bran 1000g / L, soybean meal 200g / L, solvent is water, pH nature. The composition of PDA medium is: potato 200g / L, glucose 20g / L, agar 15-20g / L, solvent is tap water, pH is natural.

Embodiment 2

[0025] The preparation of embodiment 2 fermented soybean meal

[0026] (1) Soak 1kg of soybean meal in 0.5L nutrient solution, soak at 25°C for 15min, and sterilize in a cabinet type sterilizer at 100°C for 20min to obtain the fermentation substrate; the final concentration of the nutrient solution is composed of: K 2 HPO 4 7g / L, NaCl 5g / L, (NH 4 ) 2 SO 4 4g / L, glucose 6g / L, solvent is water.

[0027] (2) According to the ratio of inoculating 1.5g wet weight of spores per kilogram of soybean meal (dry weight), inoculate the spore suspension prepared in Example 1 into the fermentation substrate of step (1), at a temperature of 28-30°C and a humidity of 100%. After 33 hours of fermentation, the culture was taken out, dried at 50°C, crushed, and passed through an 80-mesh sieve to obtain fermented soybean meal.

Embodiment 3

[0029] (1) Soak 1kg of soybean meal in 0.5L nutrient solution, soak at 25°C for 15min, and sterilize in a cabinet type sterilizer at 100°C for 20min to obtain the fermentation substrate; the final concentration of the nutrient solution is composed of: K 2 HPO4 5 / L, NaCl 3 / L, (NH 4 ) 2 SO 4 4 / L, glucose 6g / L, solvent is water.

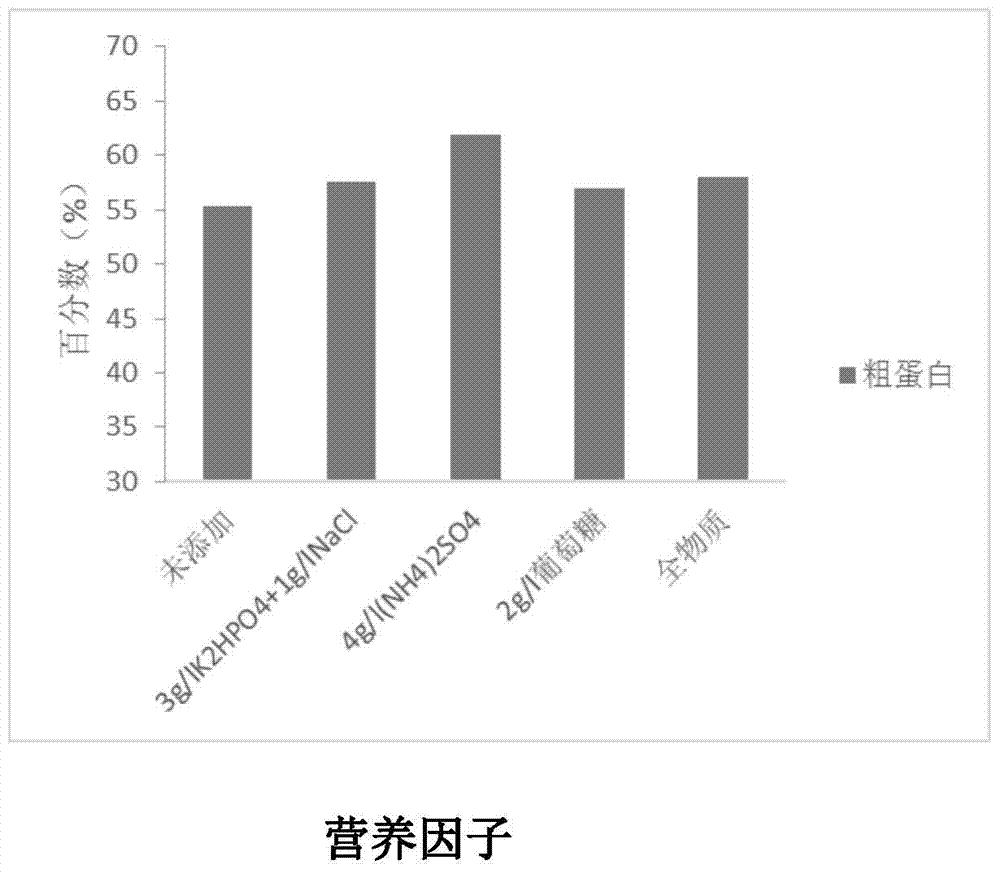

[0030] (2) According to the ratio of inoculating 1.5g wet weight of spores per kilogram of dry weight of soybean meal, the spore suspension prepared in Example 1 was inoculated into the fermentation substrate, and fermented and cultivated at 28° C. and 100% humidity respectively for 0, 24, and 33, 42, 51, 60 hours, 3 repetitions for each treatment. After the cultivation, the culture was taken out, dried at 50°C, crushed, and passed through an 80-mesh sieve to obtain fermented soybean meal. The protein content of fermented soybean meal in each group was detected by the Kjeldahl method, and the results are shown in figure 1 As shown, it was found tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com