Industrial plant for drying and/or conditioning flexible laminar surfaces

A kind of industrial equipment and flexible technology, applied in lighting and heating equipment, leather drying, progressive dryer, etc., can solve the problems of lack of uniformity in leather treatment and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

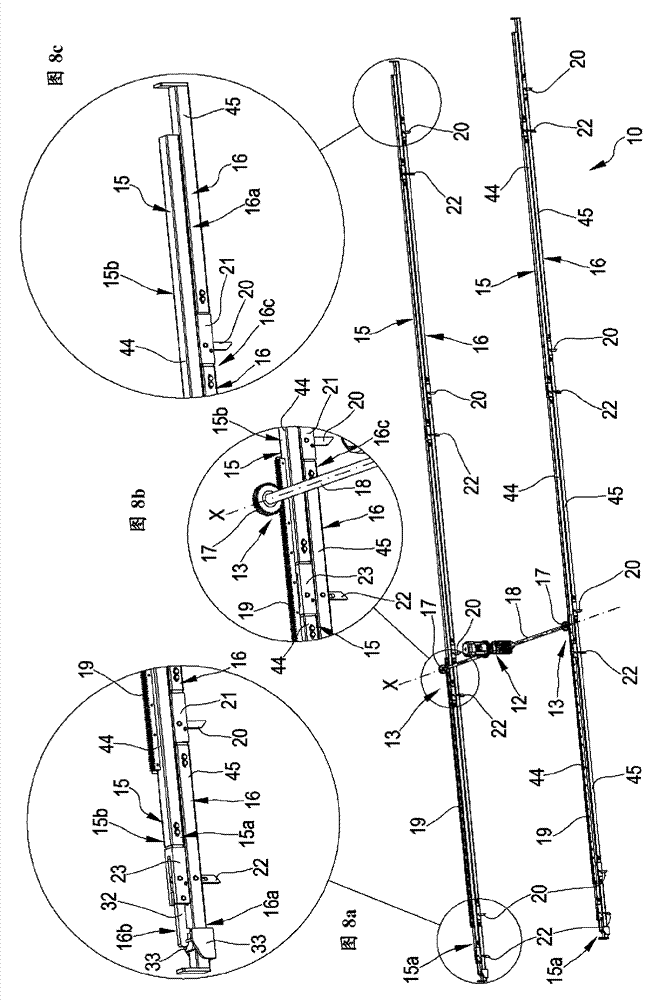

[0048] exist figure 1 Industrial equipment for drying and / or conditioning flexible laminated surfaces, such as skins or leather in the tanning industry, is shown in , which is indicated by the general number 1 in this figure.

[0049] As can be seen, the industrial plant 1 for drying and / or conditioning comprises:

[0050] - An operating tunnel indicated in its entirety by number 2, which is mainly formed according to the linear direction Z and is provided with air conditioning means 3 (such as for example axial fans 26) and / or traction mechanisms (which are not visible and are mounted by, for example consisting of hydraulic mechanisms in the operating tunnel 2), which are adapted to act on the flexible laminated surfaces, drying them and / or stretching them according to predetermined treatment and / or tensioning cycles;

[0051] - a plurality of support frames 4, each adapted to receive a pair of flexible laminated surfaces not presented for simplicity, to hold them in an exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com