High-voltage electroscope

An electroscope and high-voltage technology, which is applied in the field of high-voltage piezoelectric electrical appliances, can solve the problems of reducing the work efficiency of operators, misjudgment of high-voltage equipment without power, loss of electroscopes, etc., so as to increase work efficiency and work safety factor, and test results Accurate and prevent accidental release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

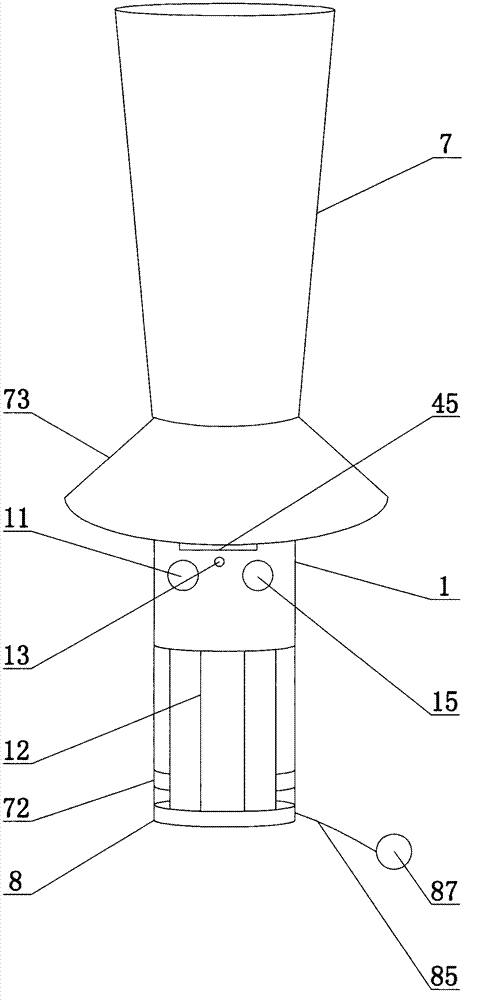

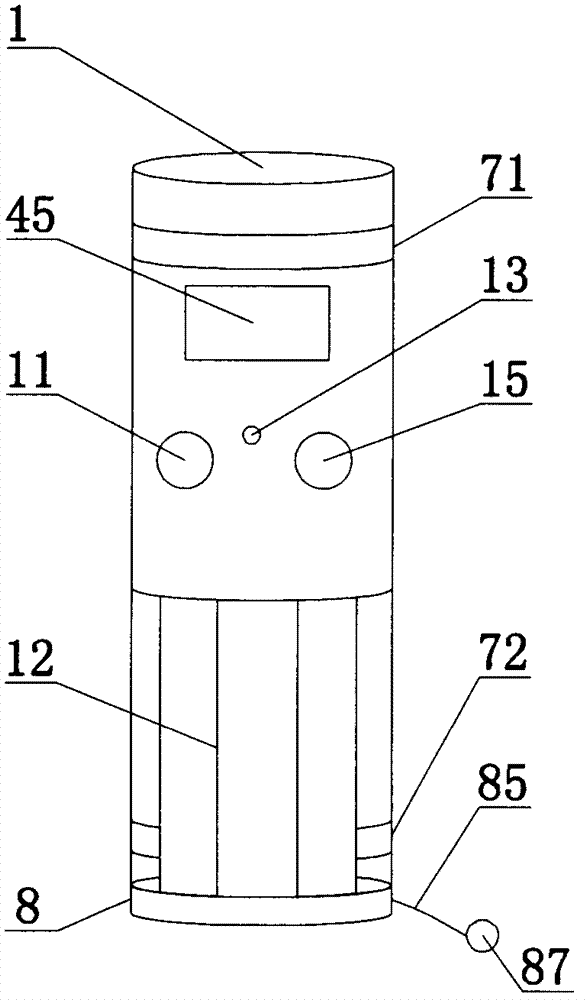

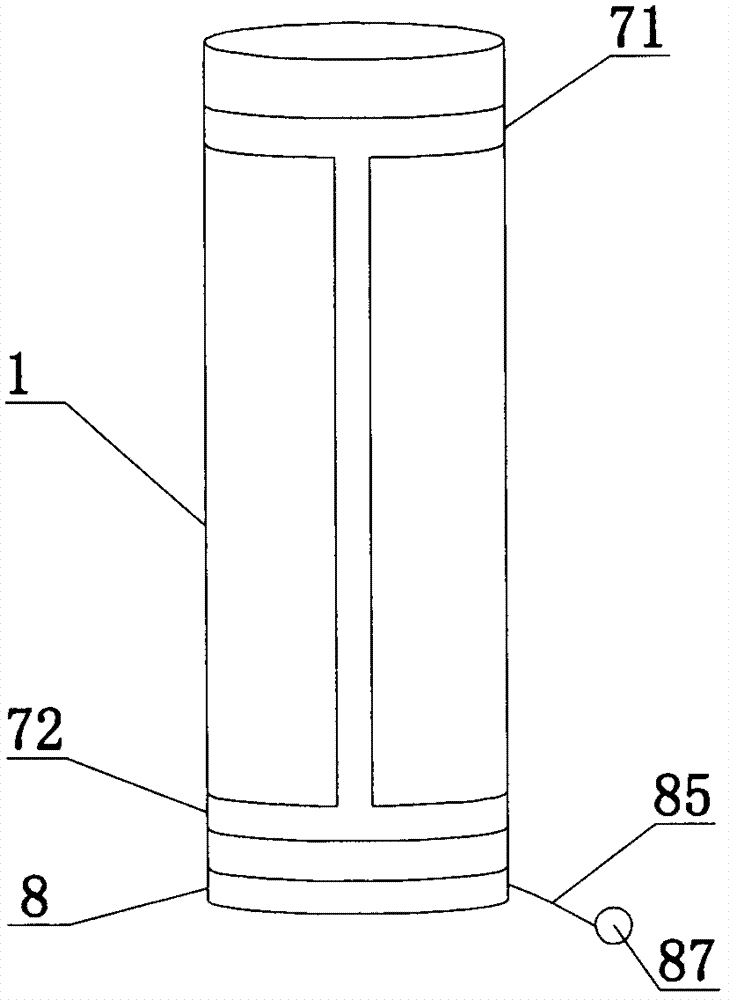

[0052] A high-voltage electroscope, comprising an electroscope body 1, a self-inspection device 14 is arranged in the electroscope body 1, the self-inspection device 14, a signal acquisition module, a signal processing module, a signal detection and analysis module 6 and a power supply 2, The power supply 2 is provided with a solar panel and an external power supply 2, and the electroscope body 1 is provided with a charging indicator light 13, which does not need to contact charged equipment, and can detect whether the circuit or equipment is charged at a long distance, and the circuit that may be charged Or the device collects and processes the signal, obtains the result, and determines whether the line or device is charged. The signal acquisition module includes a laser range finder and an ultraviolet sensor 32, the laser range finder is used to detect the distance from the electroscope to the object to be measured, and can also be used as a front sight of the electroscope, a...

Embodiment 2

[0054] A high-voltage electroscope, including an electroscope body 1, a signal acquisition module, a signal processing module, a signal detection and analysis module 6, and a power supply 2 are arranged in the electroscope body 1, and a long-distance detection line can be detected without contacting live equipment. Or whether the equipment is charged, collect and process the signal of the line or equipment that may be charged, get the result, and determine whether the line or equipment is charged. The signal acquisition module includes an ultrasonic rangefinder and an ultraviolet sensor 32. The ultrasonic rangefinder is used to detect the distance from the electroscope to the object to be measured, and the collected distance is input into the signal acquisition module, and the detected distance is calculated according to the set parameters. voltage value. The ultraviolet sensor 32 is provided with a capacitor 33, a drive circuit 34, a rectifier 35 and a filter 36. After the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com