High-voltage electroscope for robot

A technology of electroscope and robot, which is applied in the field of electroscope, can solve the problems of electric shock, inconvenient implementation, unfavorable robot extraction, etc., and achieve the effect of avoiding live operation and accurate electroscope results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

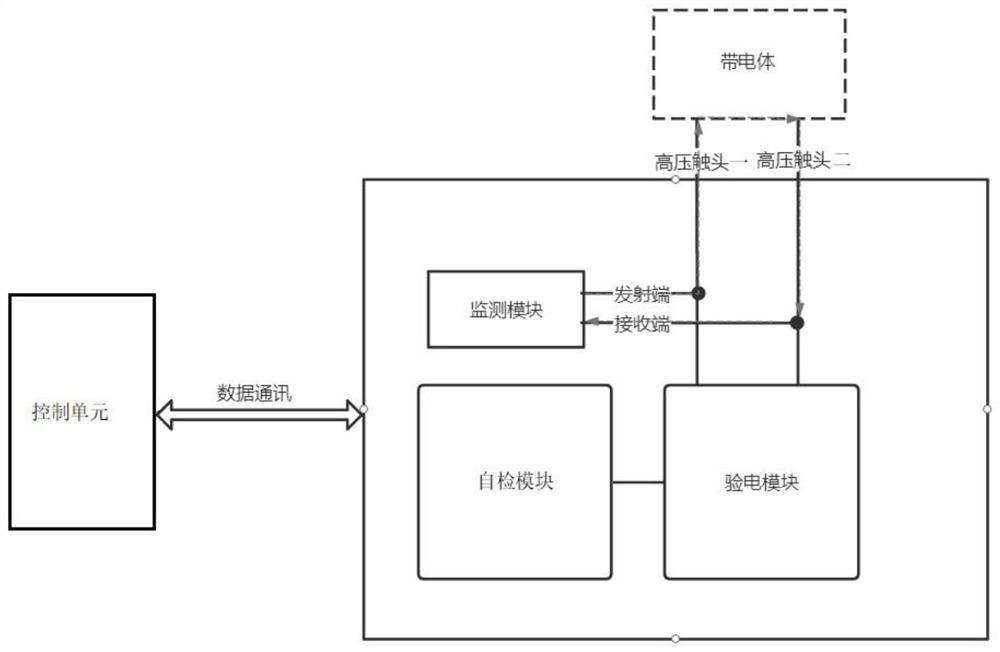

[0023] see figure 1 A high-voltage electroscope for a robot, comprising an electroscope module, a self-inspection module, a high-voltage contact body, a control unit, and a monitoring module; the electroscope module is respectively connected to the high-voltage contact body, the self-inspection module, and the control unit; The electric inspection module is also connected to the earth; the monitoring module is arranged between the electric inspection module and the high-voltage contact body; the control unit is respectively connected with the electric inspection module, the self-inspection module and the monitoring module; the high-voltage contact The head body is used to contact the electrified body; the self-inspection module can generate high-voltage signals at the same level as the electrified body; the control unit can control the self-inspection module to verify whether the electric test module is valid; the control unit can monitor the high-voltage through the monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com