Self-circulating posterior grouting bored pile construction method

A technology of bored piles and construction methods, which can be applied to sheet pile walls, foundation structure engineering, construction, etc., and can solve the problems of mud pollution to the environment, and achieve the effects of saving soil and water resources, improving bearing capacity, and benefiting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

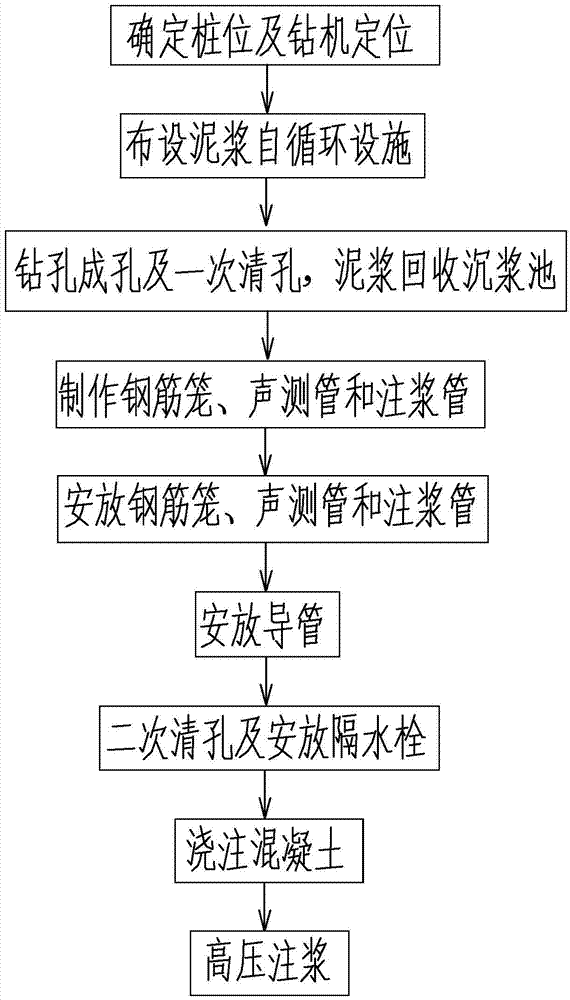

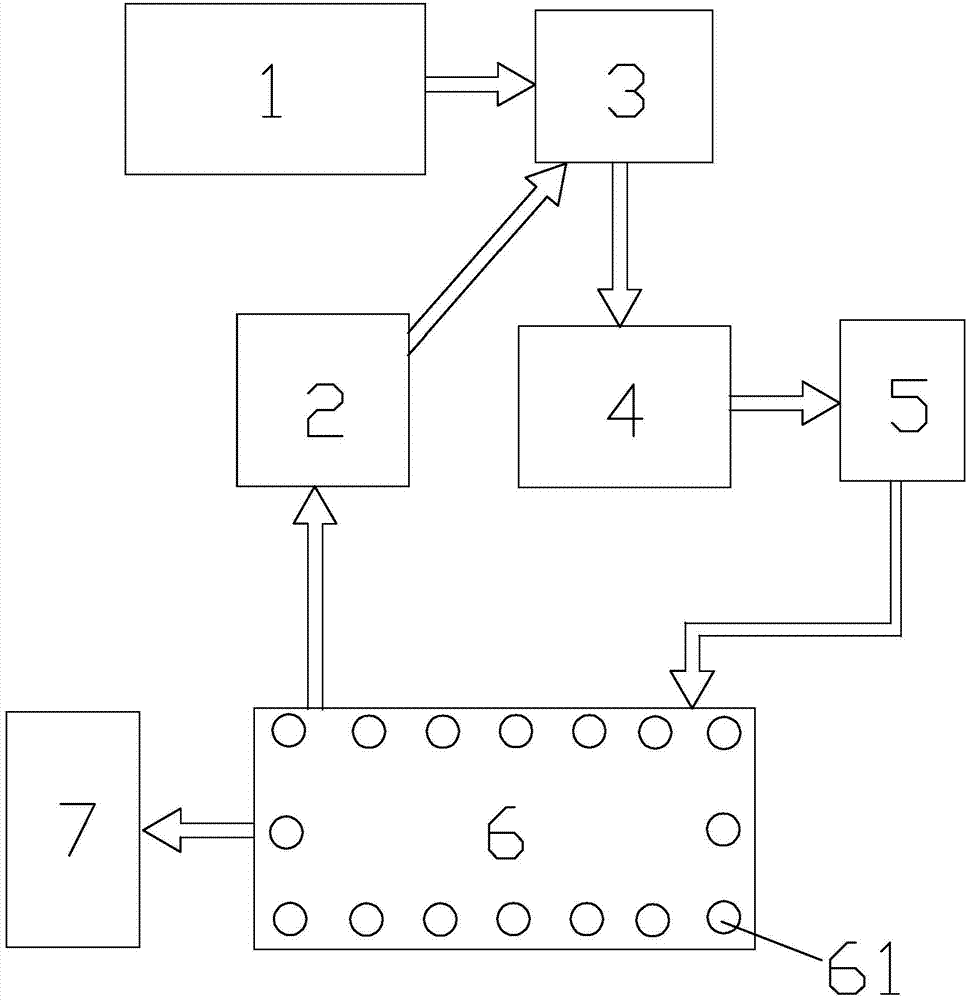

[0048] see Figure 1 to Figure 4 , The self-circulation post-grouting bored pile construction method of this embodiment is suitable for bored pile construction with a large construction site and high requirements for pile body quality.

[0049] The self-circulation post-grouting bored pile construction method of this embodiment mainly includes the following steps:

[0050] ①Determine the pile position and drilling rig positioning:

[0051] The first step: according to the master plan, coordinates and elevation reference points provided by the owner, measure and place the axis, pile position and elevation control points according to the drawings;

[0052] Step 2: Number each pile according to the pile position map, and control the coordinates according to the general plan, copy out the pile position coordinates of each pile one by one, use the total station to stake out on-site, and hang the stake out points on the spot Pile number plate;

[0053] Step 3: Re-test the pile position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com