[0004] 1. The on-line measurement of

coating thickness needs to use a thickness gauge. Due to the

process requirements of galvanizing production, the installation position of the thickness gauge is often far away from the

air knife, resulting in a large measurement lag in the

system. At the same time, in the actual plating In zinc production, affected by upstream and downstream production capacity, the speed of the galvanizing line changes at any time, so the measurement

lag time of the

system is not a fixed value, but time-varying (generally 70 seconds to 120 seconds), subject to Due to the influence of external disturbances, the thickness of the coating has been in a fluctuating state. Directly using the information of the thickness gauge for closed-

loop control of coating thickness feedback will result in a large overshoot and a long adjustment time, which further increases the difficulty of thickness control in galvanized production. , leading to large fluctuations in coating thickness and difficult to control product quality;

[0005] 2. The production process of galvanizing is affected by many complex physical factors such as

aerodynamic force and boundary flow layer. The final thickness of the zinc layer is the result of the

joint action of variables such as

air knife pressure,

air knife distance, and

production line speed. These variables The principle of influence on the thickness of the coating is relatively complex and there are many disturbance factors, which have strong nonlinearity. It is difficult to establish an accurate

system model by using the traditional mechanism modeling method;

[0006] 3. There are various external random disturbances in the actual

industrial site, such as: changes in the composition and temperature of the zinc liquid, changes in plate shape, fluctuations in air knife pressure, etc. These external disturbances will affect the thickness of the coating and cause a large quality fluctuations

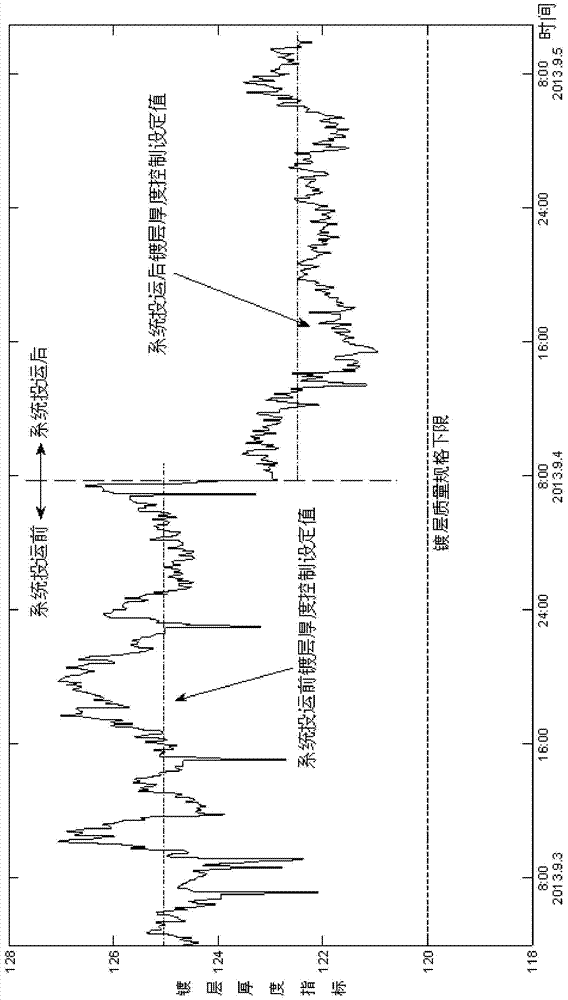

Due to the lack of effective control technology to overcome the above difficulties, coating thickness control has always been a difficult problem in galvanizing production. At present, most galvanizing lines in domestic iron and steel enterprises adopt manual control based on feedback information from thickness gauges. This method is restricted. Due to the operator's experience and sense of responsibility, the control accuracy is low, the anti-disturbance is poor, the

transition time is long when the product specification changes, and the quality fluctuates greatly. It is often impossible to obtain the expected product quality, and even irregular operations that violate the

process requirementsUneven coating and large fluctuations in thickness force manufacturers to artificially increase the setting value of coating thickness to ensure that product quality still meets the requirements of thickness control indicators when the working conditions fluctuate greatly. high cost

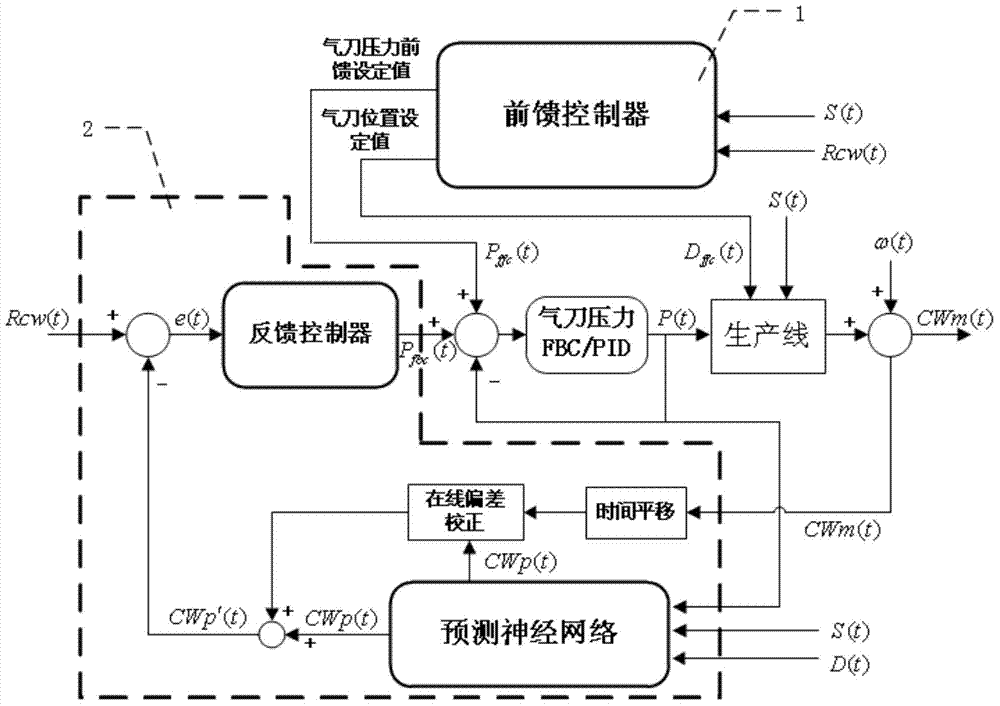

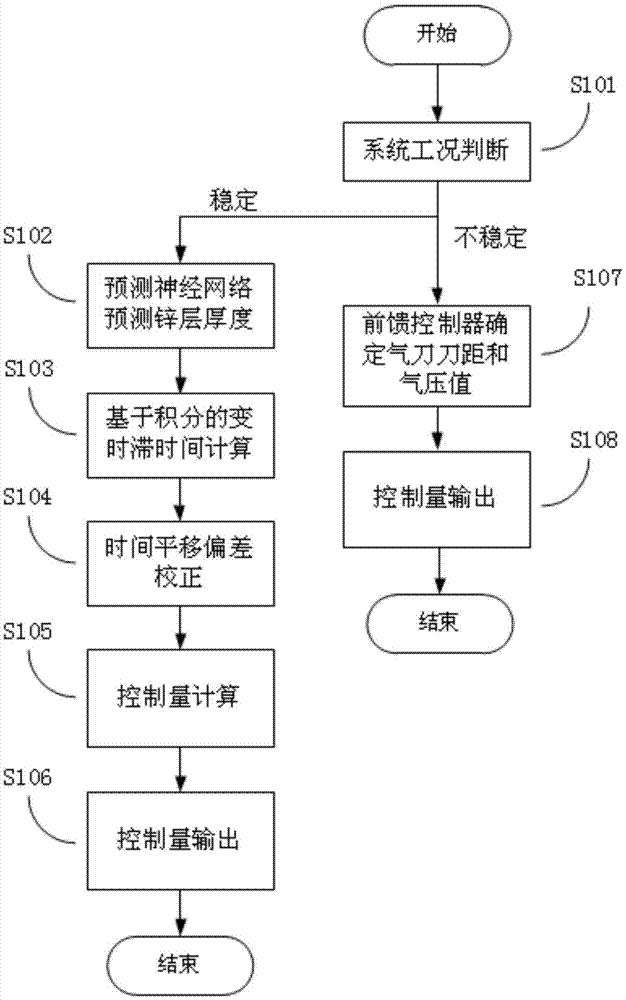

In order to solve the above problems, there are related domestic patents and literatures that propose a model-based feedforward /

feedback control system, such as the patent "An

Automatic Control System for Hot-dip Galvanizing Line

Coating Thickness" with the publication number CN102912275A, whose model is based on the mechanism , based on the production history data, the least square method and other methods are used to establish piecewise

linear fitting parameters. Due to the use of the feedforward + feedback design method, the method proposed in this invention has the advantages of overcoming the fluctuation of coating quality caused by measurable and uncontrollable disturbances. However, for the highly nonlinear production process of galvanizing, it is difficult for the linear segment model to accurately and comprehensively reflect the nonlinear characteristics of the system in the galvanizing process, and the prediction accuracy of the model is not high, which restricts the quality of system control At the same time, the

feedback controller proposed in this patent directly uses the information of the thickness gauge for

feedback control. As mentioned above, in the production process of galvanizing, the installation position of the thickness gauge is subject to the requirements of the process and the actual

production line layout It is often installed at a position far behind the

actuator (air knife). In addition, affected by the upstream and downstream production capacity, the speed of the galvanizing

production line changes at any time, resulting in a large time-varying measurement lag. The above method ignores the influence of time-varying coating thickness measurement and large pure lag factors, which will easily lead to the occurrence of system fluctuations, overshoot and longer

transition time; , Sichuan

Metallurgy, 2006: 28 (6)), introduced the coating thickness control system provided by VAI company. The feedforward controller of this system mainly compensates for the change of line speed by adjusting the air pressure of the air knife, while the

feedback controller takes priority Use air knife pressure adjustment, when it is saturated, use air knife distance to adjust

The calculation of feedforward and feedback control quantities mentioned in this document is based on sensitivity calculation, and the relationship between coating thickness and speed, air knife pressure, and air knife spacing is linearized near the current working point, and there is also a control The accuracy is low, the model cannot be corrected online, and the time-varying and large lag problem of feedback cannot be effectively solved.

Therefore, although the current

automatic control system for coating thickness in China adopts a feedforward + feedback architecture, the

control effect is not ideal due to factors such as the large lag in measurement and the limitations of the prediction model itself.

Login to View More

Login to View More  Login to View More

Login to View More