Device and method for ultrasonic impact strengthening of shaft type part welding seams

A shaft parts, ultrasonic impact technology, applied in the field of welding seam strengthening of parts, to achieve the effect of improving fatigue performance, less restrictions, and a wide range of process applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

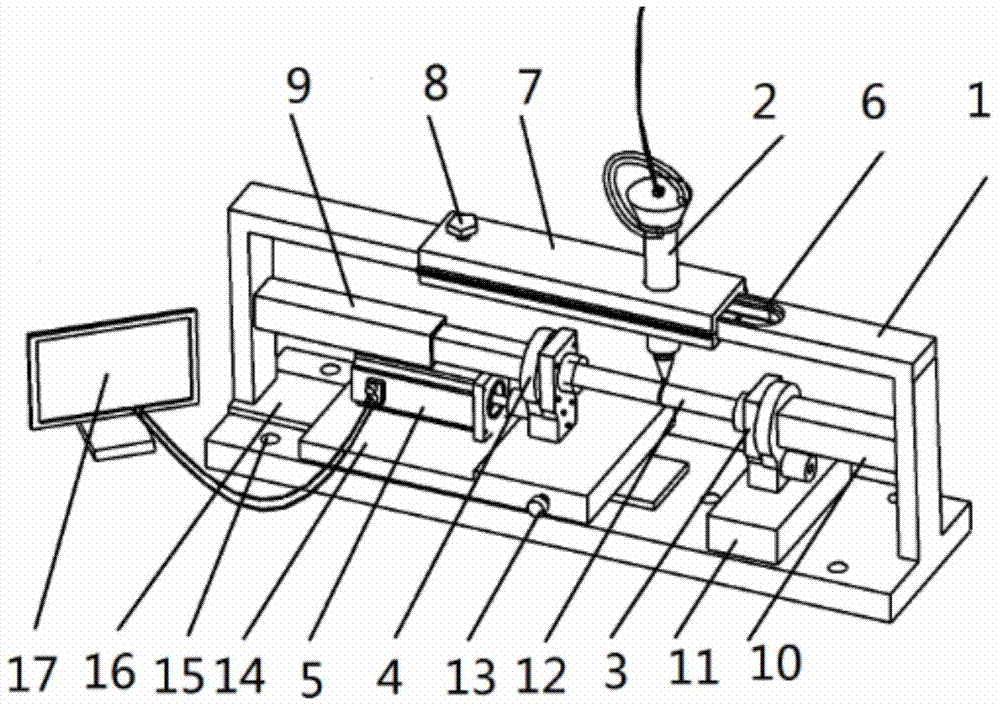

[0027] The workpiece is a hollow tube half shaft, which is composed of left and right connecting rods and a hollow tube in the middle. The materials are 55#, 40Cr, and 45# respectively, the shaft radius is Φ20mm, and the total length is 440mm. There are two welds. 6mm. Through the movement of the mobile platform 14 and the telescopic support beam 9, the position of the left hollow shaft rotating platform 4 is controlled to install and locate the half shaft of the hollow tube, which is connected by an elastic coupling. The detachable and movable slider 7 controls the movement of the ultrasonic impact gun 2 so that the impact needle is vertically located above the weld at the left end. The number of needles is 2, the diameter is 3mm, and the hardness is at least higher than HRC55; the specific parameters for selecting the ultrasonic impact gun are: impact The frequency is 15KHz, the output power is 500W, the output amplitude is 100um, the cooling method is air cooling, the volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com