Method for separating acetone/DMF/water ternary system by rectifying through high- and low- pressure towers

A rectification separation and ternary system technology, applied in the separation/purification of carboxylic acid amides, separation/purification of carbonyl compounds, organic chemistry, etc., can solve problems affecting product quality, complex process flow, and increased separation costs, etc., to achieve The effect of improving product purity, simple process and reasonable device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

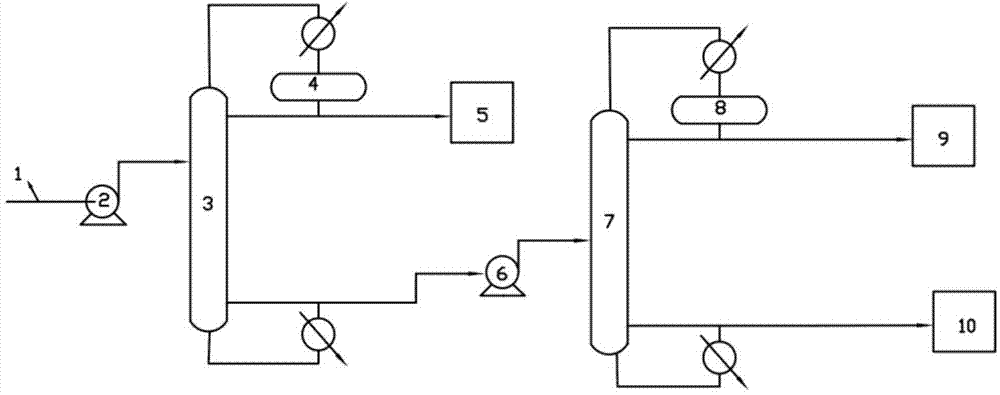

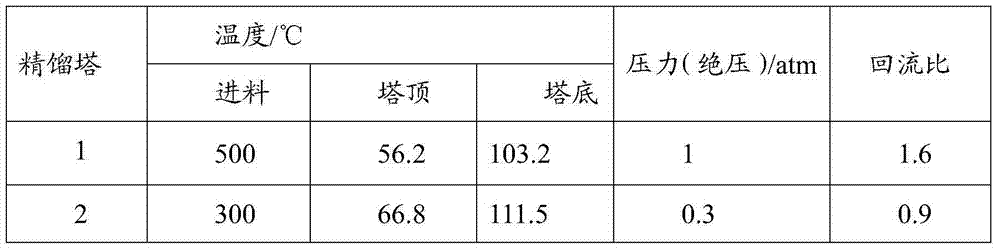

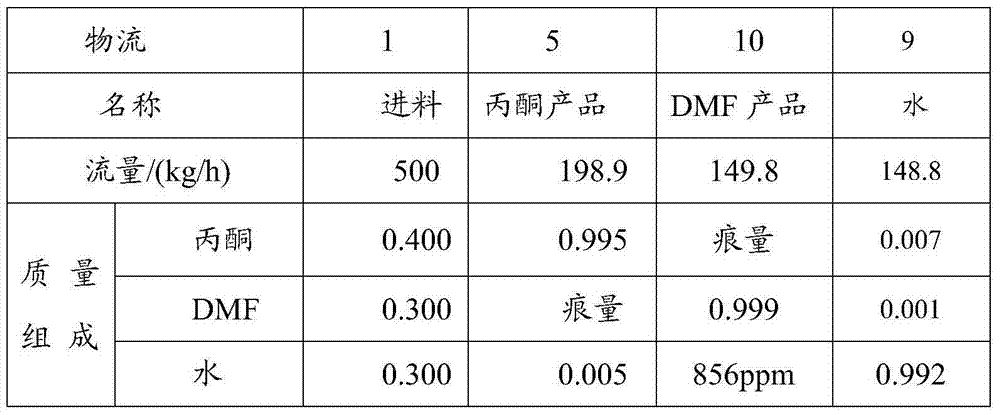

[0043]Feed flow rate is 500kg / h, temperature is 15°C, pressure is 1atm (absolute pressure), mass composition: acetone 40%, DMF 30%, water 30%. The diameter of the atmospheric tower is 395 mm, the number of theoretical plates is 30, and the feed position is 22; the diameter of the vacuum tower is 443 mm, the number of theoretical plates is 25, and the feed is at the 15th block.

[0044] The operating process parameters of the double-tower rectification system are shown in Table 1.1, and the system feed and product logistics are shown in Table 1.2. As can be seen from the data in the table, the double-tower rectification method of the present invention is adopted. After separation: the acetone product has a purity of 99.5%, DMF The product purity reaches 99.9%; the yield of acetone reaches 99.9%, and the yield of water reaches 99.2%.

[0045] Table 1.1 Process and operating parameters of the double-column distillation system

[0046]

[0047] Table 1.2 Feed and product flow ...

Embodiment 2

[0050] Feed flow rate is 600kg / h, temperature is 25°C, pressure is 1atm (absolute pressure), mass composition: acetone 50%, DMF 20%, water 30%. The diameter of the atmospheric tower is 460 mm, the number of theoretical plates is 35, and the feed is at the 22nd block; the diameter of the vacuum tower is 680 mm, the number of theoretical plates is 35, and the feed is at the 20th block.

[0051] The operating process parameters of the double-column distillation system are shown in Table 2.1, and the system feed and product logistics are shown in Table 2.2. As can be seen from the data in the table, adopt the double-tower rectification method of the present invention, after separation: the acetone product purity reaches 99.6%, the DMF product purity reaches 99.9%, the water purity reaches 99.6%; the yield of acetone reaches 99.5%, the DMF The yield reaches 99.9%, and the yield of water reaches 99.5%.

[0052] Table 2.1 Process and operating parameters of the double-column distill...

Embodiment 3

[0057] The feed flow rate is 600kg / h, the temperature is 15°C, the pressure is 1atm (absolute pressure), the mass composition: acetone 60%, DMF 20%, water 20%; the diameter of the atmospheric column is 470mm, the number of theoretical plates is 33, and the 21st block Feeding: The diameter of the vacuum tower is 650mm, the number of theoretical plates is 30, and the feed is at the 20th block.

[0058] The operating process parameters of the double-tower rectification system are shown in Table 3.1, and the system feed and product logistics are shown in Table 3.2. It can be seen from the data in the table that the double-tower rectification method of the present invention is adopted. After separation: the acetone product has a purity of 99.6%, DMF The purity of the product reaches 99.9%, the purity of water reaches 99.4%, the yield of acetone reaches 99.5%, the yield of DMF reaches 99.9%, and the yield of water reaches 99.3%.

[0059] Table 3.1. Process and operating parameters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com