Fully-automatic numerical control ball bearing inner ring groove grinder

A technology of inner ring groove and ball bearing, which is applied in the field of bearing processing to increase processing types and save money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

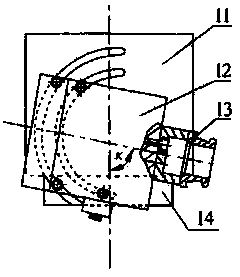

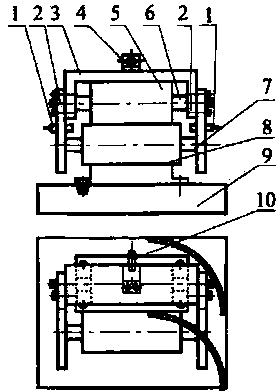

[0010] like figure 1 , figure 2 As shown, a fully automatic CNC ball bearing inner ring groove grinding machine includes a bed, a reciprocating table, a grinding wheel axle box, a workpiece axle box 12, a grinding wheel dresser, and a workpiece feeding mechanism. The reciprocating table is installed on the bed On the body, the grinding wheel axle box is installed on the bed at the rear side of the reciprocating workbench, the grinding wheel is installed on the grinding wheel axle box, the grinding wheel dresser and the workpiece axle box 12 are all installed on the reciprocating workbench, and the workpiece axle box seat 11 is provided with two Arc-shaped groove, sliding screw is installed in the groove, and the sliding screw is connected with the workpiece shaft box 12, so that the workpiece 13 axis forms an angle with the grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com