A high heat transmission soldering iron tip suitable for soldering in small spaces

A soldering iron head and small space technology, applied in the direction of soldering iron, soldering station, welding equipment, etc., can solve the problems of unsatisfactory process, poor working conditions, long time, etc., meet reliability requirements, improve work efficiency, and ensure reasonable sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

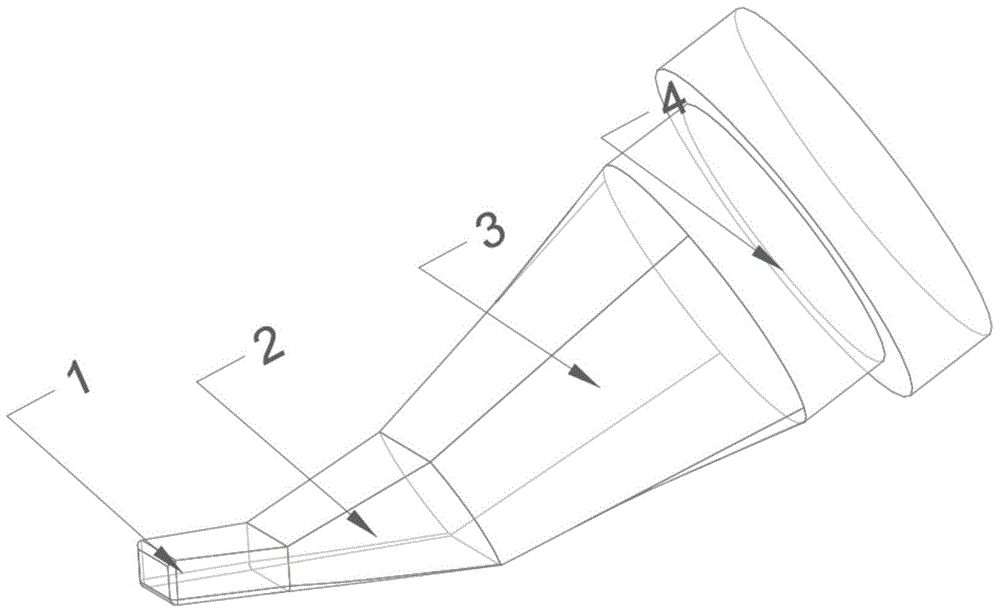

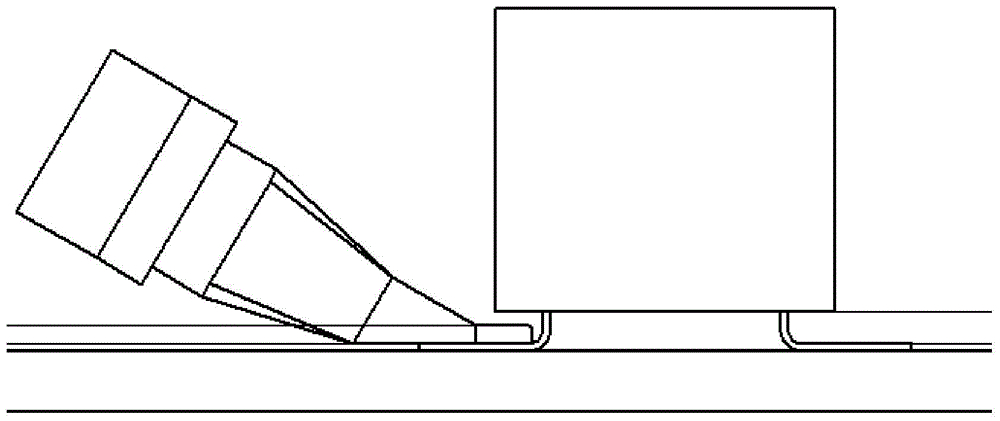

[0027] like figure 1 , 2 As shown, the present invention provides a high heat transmission soldering iron tip suitable for soldering in a small space, including: a tip 1, a first transition part 2, a second transition part 3 and a soldering iron assembly part 4;

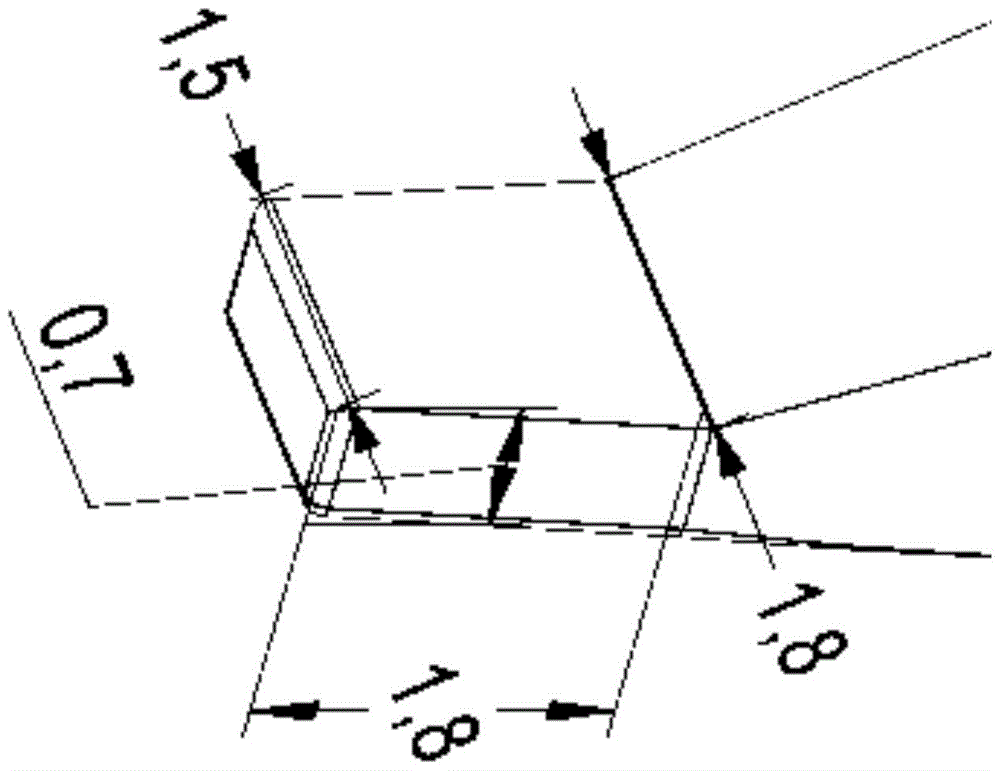

[0028] Both the head end face and the tail end face of the tip 1 are rectangular, the length of the long side of the head end rectangle is less than the length of the long side of the tail end rectangle, and the length of the wide side of the head end rectangle is equal to the width of the tail end rectangle, There is a uniform transition between the end surface of the head and the end surface of the tail, the shape of the bottom surface and the top surface of the tip 1 are the same, both are isosceles trapezoidal; the end surface of the tail of the tip 1 matches and is fixedly connected to the end surface of the head of the first transition part 2 , the tail of the first transition part 2 is connected to the head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com