Extrusion rod compressing apparatus for extruder

A technology of pressing device and extrusion rod, which is applied in the direction of metal extrusion, pressure head/punch rod, metal processing equipment, etc. It can solve the problems that it is difficult to fit the mating surface in place and the center positioning of the extrusion rod is unreliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

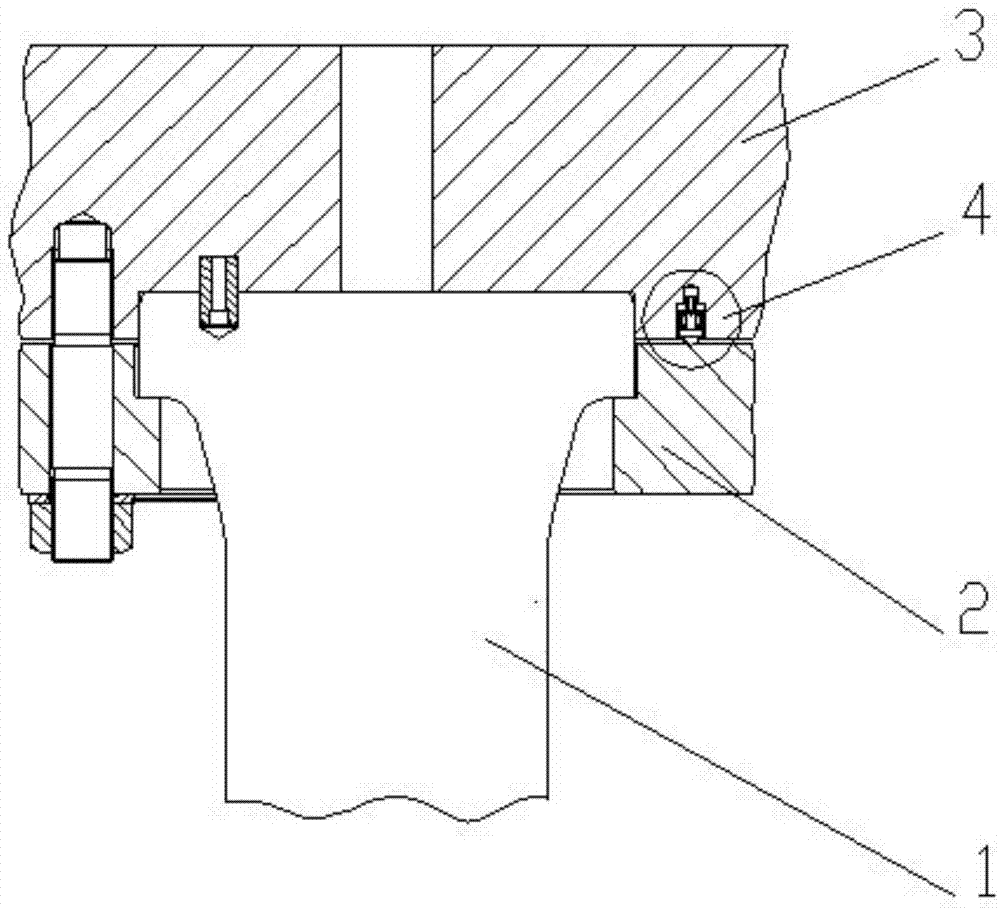

[0023] Such as figure 1 Shown is an extrusion rod pressing device for an extrusion machine, comprising an extrusion rod 1, an extrusion rod gland 2, an extrusion rod shaft pad 3 and an elastic bolt structure 4, and the extrusion rod gland 2 is screwed On the extruding rod 1 , the end of the extruding rod 1 is punched and fixed in the extruding rod shaft pad 3 ; the extruding rod gland 2 and the extruding rod shaft pad 3 are fixed by an elastic bolt structure 4 .

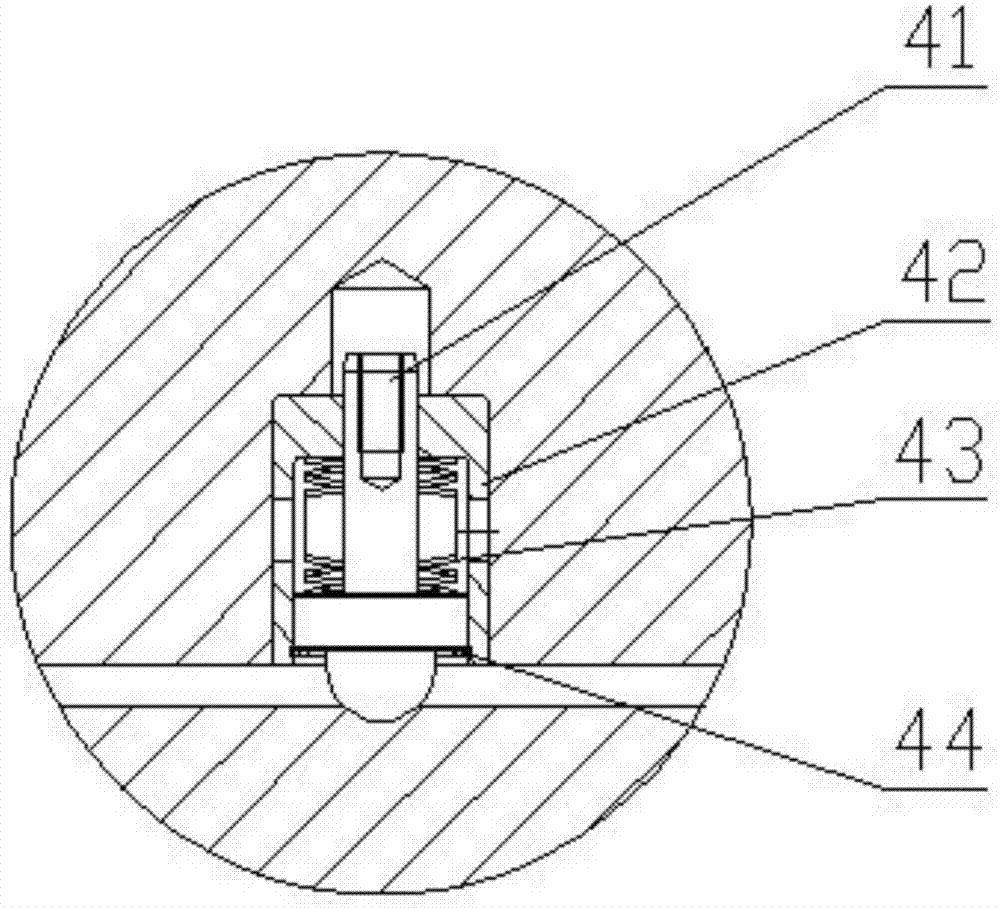

[0024] Such as figure 2 As shown, the elastic bolt structure 4 includes a jacking shaft 41, a fixed seat 42, a disc spring and a retaining ring 44, the jacking shaft 41 includes a first end and a second end, and the first end of the jacking shaft 41 is fixed on the extruded In the compression rod shaft pad 3, the second end of the top shaft 41 is fixed with a retaining ring 44, the second end of the top shaft 41 is connected to the extrusion rod gland 2, and the top shaft 41 and the retaining ring 44 are fixed on t...

Embodiment 2

[0027] Such as figure 1 Shown is an extrusion rod pressing device for an extrusion machine, comprising an extrusion rod 1, an extrusion rod gland 2, an extrusion rod shaft pad 3 and an elastic bolt structure 4, and the extrusion rod gland 2 is screwed On the extrusion rod 1 , the end of the extrusion rod 1 is welded and fixed in the extrusion rod shaft pad 3 ; the extrusion rod gland 2 and the extrusion rod shaft pad 3 are fixed by an elastic bolt structure 4 .

[0028] Such as figure 2 As shown, the elastic bolt structure 4 includes a jacking shaft 41, a fixed seat 42, a spring and a retaining ring 44, the jacking shaft 41 includes a first end and a second end, and the first end of the jacking shaft 41 is fixed on the extrusion In the rod shaft pad 3, the second end of the top shaft 41 is fixed with a retaining ring 44, the second end of the top shaft 41 is connected to the extruded rod gland 2, and the top shaft 41 and the retaining ring 44 are both fixed on the fixing sea...

Embodiment 3

[0031] Such as figure 1 Shown is an extrusion rod pressing device for an extrusion machine, comprising an extrusion rod 1, an extrusion rod gland 2, an extrusion rod shaft pad 3 and an elastic bolt structure 4, and the extrusion rod gland 2 is screwed On the extruding rod 1 , the end of the extruding rod 1 is punched and fixed in the extruding rod shaft pad 3 ; the extruding rod gland 2 and the extruding rod shaft pad 3 are fixed by an elastic bolt structure 4 .

[0032] Such as figure 2 As shown, the elastic bolt structure 4 includes a jacking shaft 41, a fixed seat 42, a spring and a retaining ring 44, the jacking shaft 41 includes a first end and a second end, and the first end of the jacking shaft 41 is fixed on the extrusion In the rod shaft pad 3, the second end of the top shaft 41 is fixed with a retaining ring 44, the second end of the top shaft 41 is connected to the extruded rod gland 2, and the top shaft 41 and the retaining ring 44 are both fixed on the fixing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com