Touch panel, method of manufacturing touch panel, optical film substrate and method of manufacturing same

A touch panel and substrate technology, applied in the input/output process of optics, optical components, data processing, etc., can solve problems such as deterioration of electric wave characteristics, unsatisfactory, reduced visibility, etc., to maintain shading performance, prevent visible Sex-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Next, a touch panel according to an embodiment of the present invention will be described with reference to the drawings.

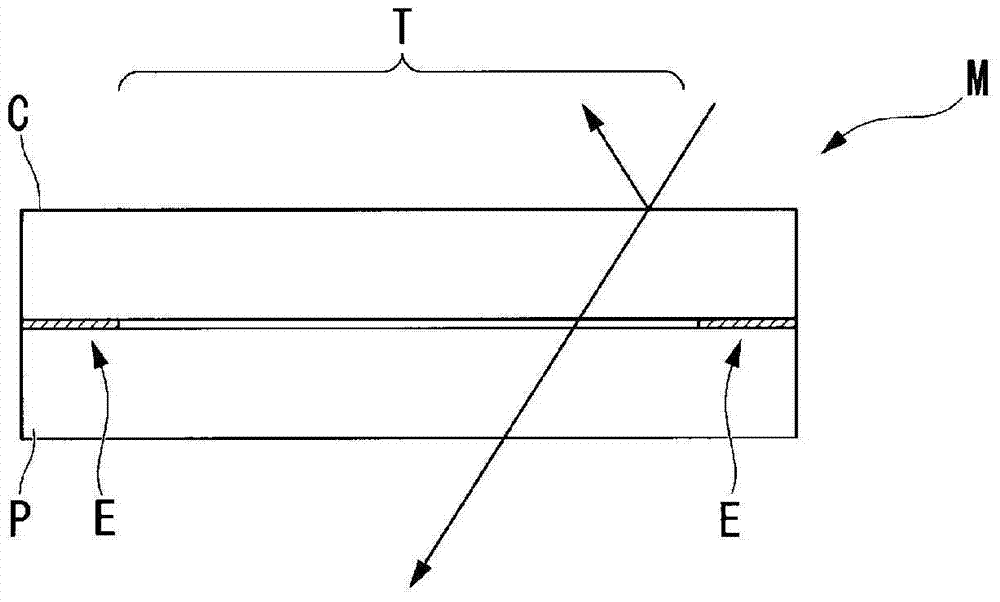

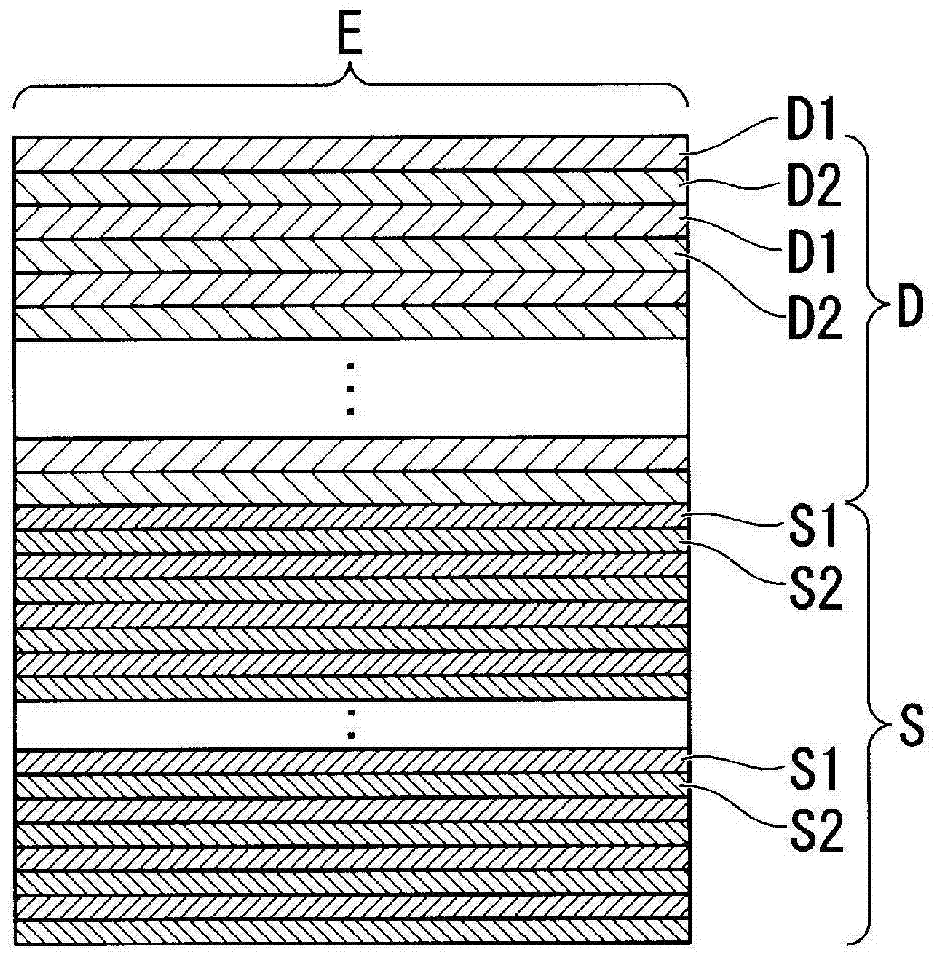

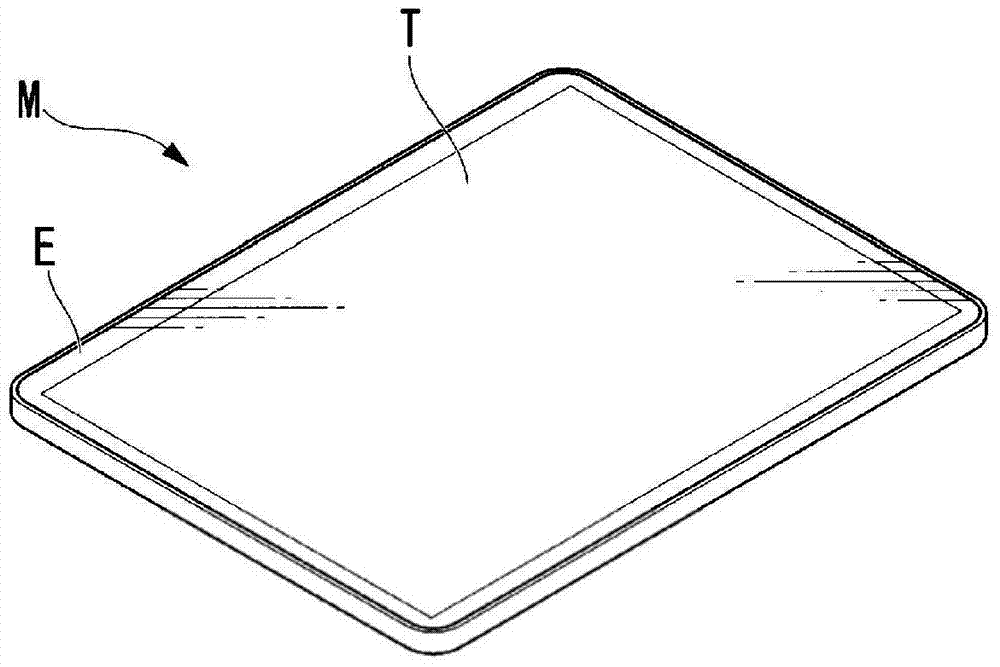

[0047] Figure 1A It is a sectional view showing the touch panel in this embodiment. Figure 1B It is an enlarged view of the edge of the touch panel in this embodiment. figure 2 It is a perspective view showing the touch panel in this embodiment. exist Figure 1A and figure 2 Among them, the symbol M is the touch panel.

[0048] In the touch panel M of the present embodiment, as Figure 1A , figure 2 As shown, a touch panel substrate P having a display region T capable of display and touch operations and a cover substrate C formed of a transmissive substrate such as glass are arranged to overlap. In addition, between the touch panel substrate P and the cover substrate C, in a region excluding the display region T, a connection portion is provided at an edge portion E around the display region T. As shown in FIG.

[0049] The touch panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com