Distributed type energy resource flue gas waste heat deep utilization system

A distributed energy and flue gas waste heat technology, applied in the field of energy systems, can solve problems such as high exhaust gas temperature of waste heat boilers, high heat consumption of energy stations, and insufficient utilization of flue gas waste heat, so as to reduce exhaust gas temperature and improve economic efficiency. Sexuality and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

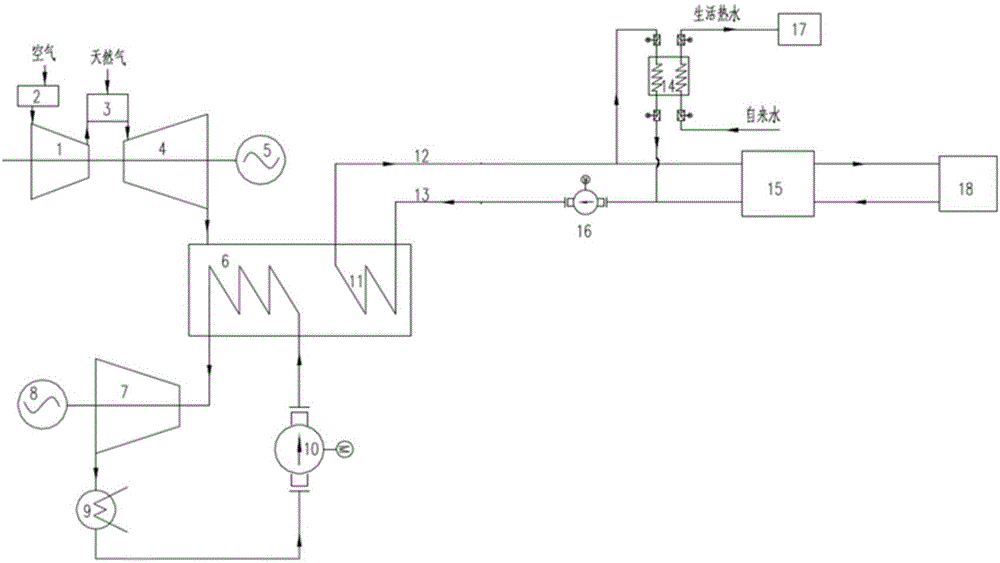

[0018] refer to figure 1 , this embodiment includes a gas turbine generator set, a steam turbine generator set, a waste heat boiler 6, a hot water heat exchanger 11 and water equipment, a gas turbine generator set includes a compressor 1, a combustion chamber 3, a gas turbine 4 and a gas turbine generator 5, The steam turbine generator set includes a steam turbine 7 and a steam turbine generator 8; the exhaust end of the gas turbine 4 is connected to the intake end of the waste heat boiler 6, and the exhaust gas from the waste heat boiler 6 is discharged into the atmosphere to form a waste heat utilization system of the gas turbine generator set; The steam output end of the waste heat boiler 6 is connected to the water inlet end of the waste heat boiler 6 through the steam turbine 7, the condenser 9, and the feed water pump 10 to form a steam engine Rankine cycle power generation circuit; the tail end of the waste heat boiler 6 is provided with a hot water exchange Heater 11, ...

specific Embodiment

[0025] The characteristics of other specific embodiments of the present invention are: on the basis of specific embodiment 1, one of the domestic hot water user 17 and the cold / heat user terminal 18 is omitted. All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com