A collapse self -determined heart flexion constraint support

A buckling restraint and self-centering technology, which is applied to building components, earthquake resistance, etc., can solve problems such as self-heaviness and stiffness mutation, and achieve the effect of reducing the self-weight of the support, reducing the weight, and reducing the horizontal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

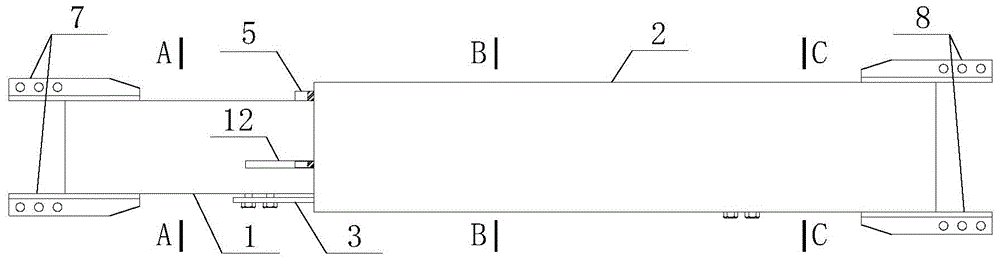

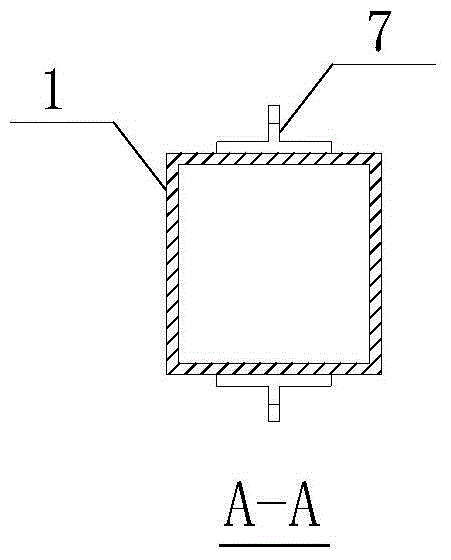

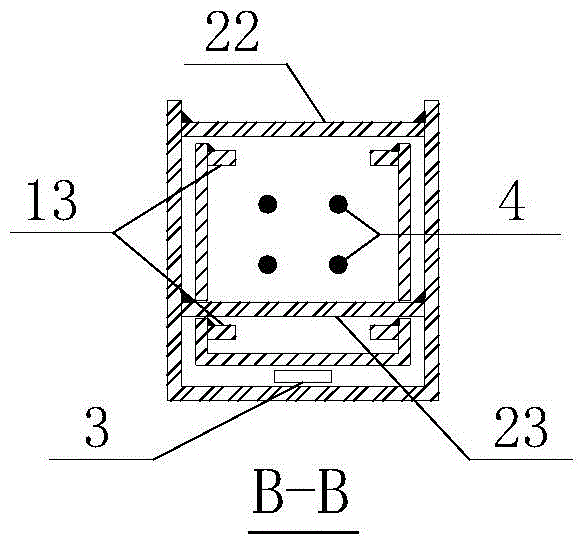

[0041] Such as Figure 1 to Figure 5 As shown, the overlapping self-centering buckling restraint support of the present invention includes a rectangular inner casing 1, a rectangular outer casing 2, an energy-dissipating core plate 3 connecting the bottom plate of the inner casing 1 and the bottom plate of the outer casing 2, and is arranged on the inner casing The first end plate 5 in the pipe 1, the second end plate 6 arranged in the outer casing 2, the pre-tension rod arranged in the inner casing 1 and anchored to the first end plate 5 and the second end plate 6 at both ends respectively 4. A part of the inner sleeve 1 is inserted into the outer sleeve 2 and overlapped with it. One end of the inner sleeve 1 inserted into the outer sleeve 2 is in contact with the second end plate 6, while the first end plate 5 is in contact with one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com