Special-shaped member turnover device and turnover device thereof

A turning device and a technology for special-shaped parts, which are applied in the field of turning over finished or semi-finished products, can solve the problems of complicated and time-consuming turning process of special-shaped parts, and achieve the effects of saving processing time, fast turning speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe in detail the overturning device for special-shaped parts and the overturning method provided by the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

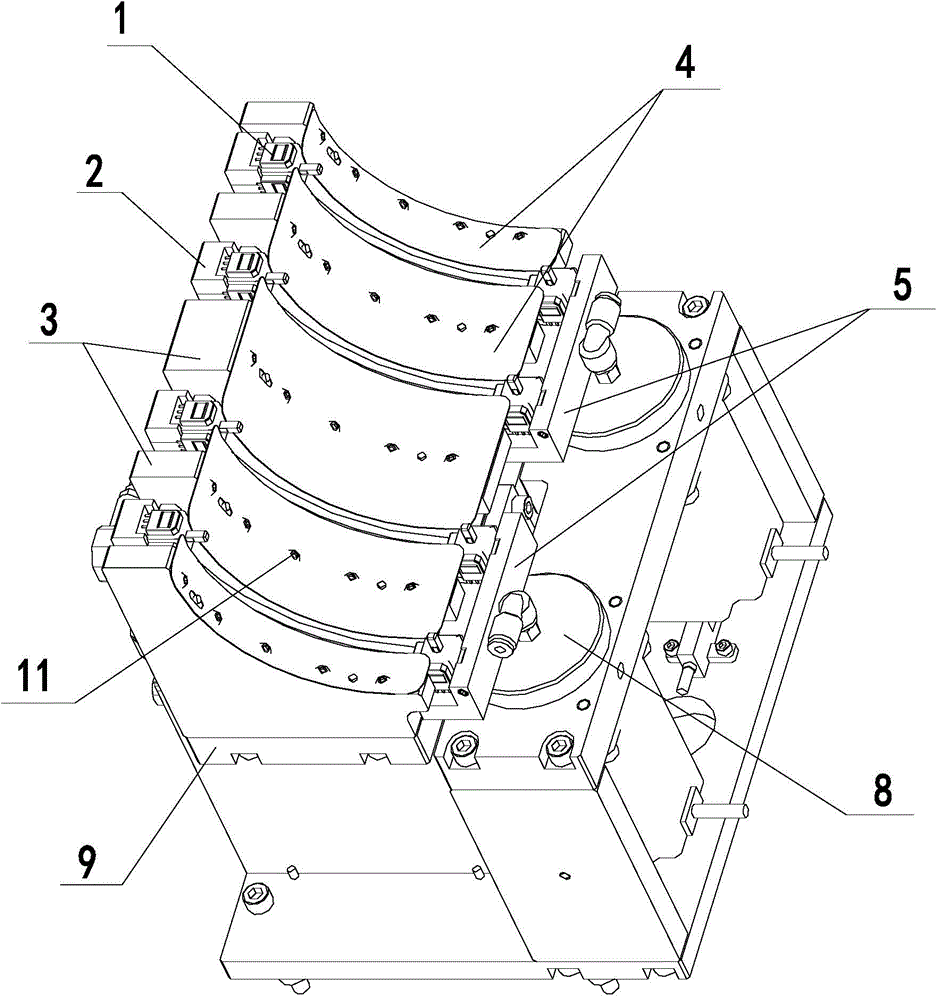

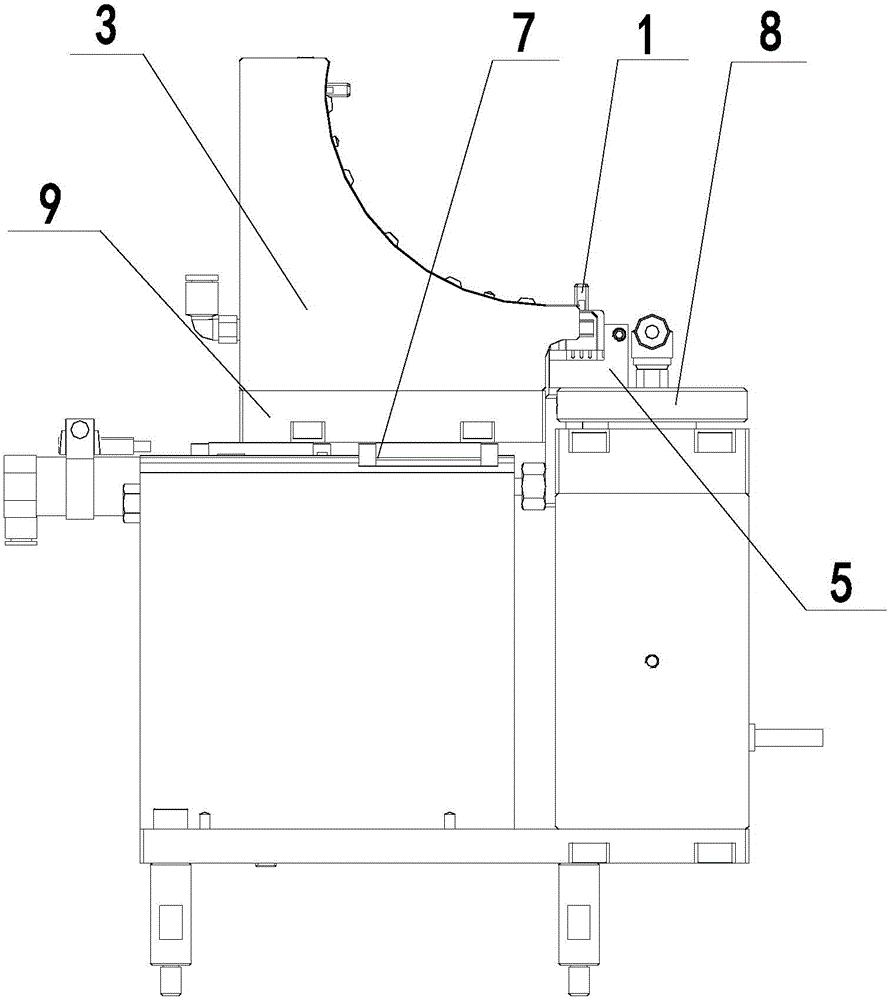

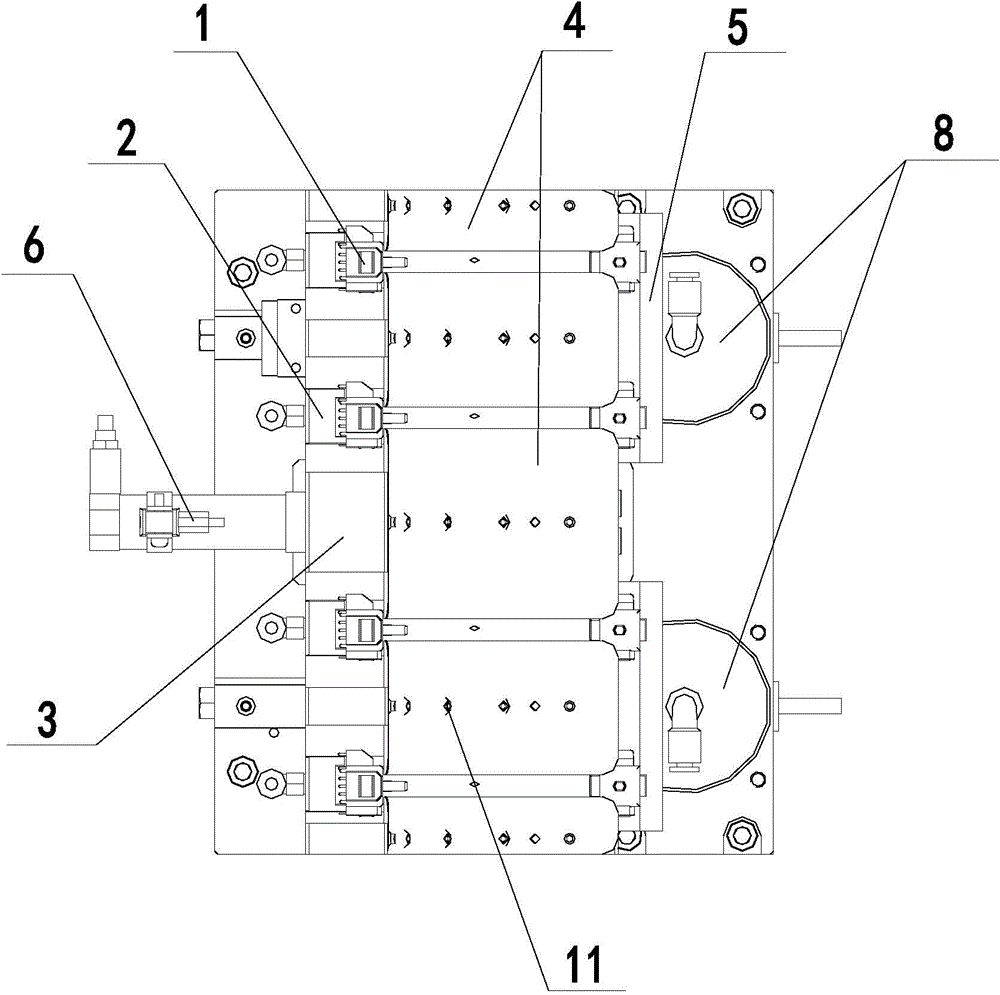

[0028] figure 1 The structure of the special-shaped piece turning device according to the embodiment of the present invention is shown.

[0029] Such as figure 1 As shown, the special-shaped piece turnover device provided by the present invention includes an arc guide rail 2, a support plate 3, a limit plate 4 and a positioning block 5; wherein, the arc guide rail 2 is an arc groove structure, and is spaced apart from the support plate 3 , the limit plate 4 is fixed on the support plate 3, and is used to limit the turning of the special-shaped piece 1; the positioning block 5 is arranged at the tail end of the arc guide rail 2, and is used for positioning the turned special-shaped piece 1; Part 1 is stu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com